Home » Bags & Pouches » Flat Bottom Pouches » Flat Bottom Pouch With Zipper

Flat Bottom Pouch With Zipper

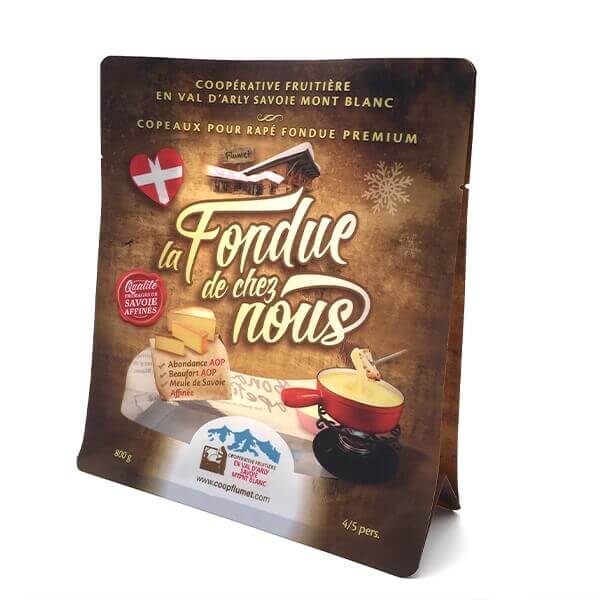

Flat bottom pouches with zipper are pouches with the completely flat bottom, also called box pouches or quad seal pouches allow specialty food creators to proudly display their brands on store shelves.

Please note that we have a MOQ for our pouch. For pouches in stock, the MOQ is 500 pcs. For customized pouches, please see the MOQ as followed:

1, Digital Printing — 500 pcs

2, Gravure Printing — 5,000pcs

Rinpac assists you throughout your project: bag shape, material, thickness, capacity and printing options. Please contact us or mark your requirements on the inquiry quotation.

Order single or thousands of items at a time. Our warehouse and flexible shipping options are available for last-minute, deadline critical orders.

- Free Sample

*Customization is always available, please mark down your need in cart or just contact us.

Specification of Flat Bottom Pouch With Zipper

| Materials | Per customer’s packaging needs. Using materials such as clear poly, metalized films, foil laminations and kraft paper. All pouches are made of food grade solvent free packaging materials. |

| Sizes | Per customers’ needs. |

| Styles | Quad sealed flat bottom |

| Resealable Features | Press-to-close zippers: Economical and commonly used |

| Tin Ties: Available in Plastic and Kraft | |

| Additional Features | Tear notches |

| Degassing Valves | |

| Knocked out windows providing a sneak peek of what’s inside: clear window, frosted window, or matte finish with glossy clear window | |

| Laser scoring or laser perforation | |

| Printing | Glossy printing |

| Matte finish printing | |

| Glossy printing with spot matte finishes | |

| Per customer’s design and requirements. | |

| Accessories | Zipper for reclosure |

| Tin Tie for reclosure | |

| Degassing Valve |

Request A Quote - Flat Bottom Pouch With Zipper

Need something helped in a short time? We’ve got a plan for you.

Related Products - Flat Bottom Pouch With Zipper

Introduction to Flat Bottom Pouches with Zipper

What are Flat Bottom Pouches with Zipper?

Flat bottom pouches with zipper closures are innovative packaging solutions designed to combine the stability of a flat bottom structure with the convenience of a resealable zipper closure. These pouches feature a flat base that allows them to stand upright on shelves, maximizing product visibility and shelf presence. The addition of a zipper closure provides easy access to the contents while preserving product freshness and integrity between uses.

Rinpac offers high quality standing pouch flat bottom. Get a free quote now.

Importance of Packaging in Product Presentation and Preservation

Packaging plays a crucial role in both product presentation and preservation. It serves as the first point of contact between consumers and products, influencing purchasing decisions and brand perception. A well-designed and visually appealing package can attract attention, communicate product features, and differentiate the product from competitors on crowded retail shelves.

Moreover, packaging serves as a protective barrier, shielding products from external elements such as moisture, light, air, and physical damage during storage, transportation, and handling. Proper packaging helps extend the shelf life of products, maintains product quality and freshness, and reduces the risk of spoilage or contamination.

Advantages of Flat Bottom Pouches with Zipper

Flat bottom pouches with zipper closures offer several advantages that make them an attractive packaging option for a variety of products. Here are some key benefits:

1. Enhanced Shelf Presence:

Flat bottom pouches with zipper closures feature a stable base that allows them to stand upright on retail shelves, maximizing product visibility and shelf space utilization. The flat bottom design creates a sleek and professional appearance, making products more appealing to consumers and increasing their chances of being noticed among competing brands.

2. Increased Product Protection:

These pouches provide superior protection for packaged products, thanks to their durable construction and zipper closure mechanism. The sturdy flat bottom base prevents tipping or spilling, reducing the risk of damage during storage, transportation, and display. Additionally, the resealable zipper closure ensures a secure seal, preserving product freshness and integrity between uses.

3. Convenient Storage and Resealing:

Flat bottom pouches with zipper closures offer convenience and ease of use for consumers. The resealable zipper allows for effortless opening and closing, enabling consumers to access the contents multiple times without compromising product quality. This feature makes the pouches ideal for storing snacks, dry goods, pet food, and other products that require convenient resealing for freshness.

Applications of Flat Bottom Pouches with Zipper

Flat bottom pouches with zipper closures are versatile packaging solutions suitable for a wide range of products across different industries. Here are some common applications of these pouches:

1. Food Packaging:

Flat bottom pouches with zipper closures are widely used for packaging various food products due to their excellent barrier properties, convenience, and shelf appeal. They are suitable for packaging snacks, dry fruits, candies, granola, coffee beans, tea leaves, and other dry goods. The resealable zipper closure helps maintain product freshness and extends shelf life, making them ideal for on-the-go snacking and pantry storage.

2. Pet Food Packaging:

These pouches are also popular for packaging pet food and treats for dogs, cats, and other pets. The flat bottom design ensures stability and prevents spillage, while the zipper closure allows pet owners to easily access and reseal the contents, keeping them fresh and flavorful. Flat bottom pouches with zipper closures are available in various sizes to accommodate different pet food quantities, from single servings to bulk purchases.

3. Pharmaceutical Packaging:

In the pharmaceutical industry, flat bottom pouches with zipper closures are used for packaging a wide range of products, including vitamins, supplements, over-the-counter medications, and first aid supplies. The secure zipper closure provides tamper-evident packaging and helps protect the contents from moisture, light, and contamination. These pouches are available in child-resistant designs for added safety and compliance with regulatory requirements.

Materials Used in Flat Bottom Pouches with Zipper

Flat bottom pouches with zipper closures are crafted from a variety of materials, each offering unique characteristics and benefits. Here are some types of materials suitable for these pouches and considerations for selecting the right material:

1. Polyester (PET):

Suitability: Polyester is a durable and lightweight material with excellent barrier properties against moisture, oxygen, and light. It provides a glossy surface for high-quality printing and branding.

Considerations: PET is ideal for products requiring premium packaging presentation and extended shelf life. However, it may not be suitable for products requiring high-temperature resistance.

2. Polyethylene (PE):

Suitability: Polyethylene is a versatile material available in various forms, including low-density (LDPE) and high-density (HDPE) options. It offers good puncture resistance and seal strength.

Considerations: PE is suitable for packaging a wide range of products, including snacks, dry goods, and pet food. It is cost-effective and can be customized with different thicknesses for specific packaging needs.

3. Aluminum Foil:

Suitability: Aluminum foil provides superior barrier properties against moisture, oxygen, light, and odors. It offers excellent heat resistance, making it suitable for products requiring extended shelf life and protection against external elements.

Considerations: Aluminum foil is commonly used in flat bottom pouches for packaging coffee, tea, nuts, and dried fruits. It provides a metallic appearance and can be laminated with other materials for added strength and barrier protection.

4. Nylon (PA):

Suitability: Nylon is a strong and flexible material known for its puncture resistance and barrier properties. It enhances the overall strength and durability of flat bottom pouches.

Considerations: Nylon is often used as a component in multilayer laminates to improve the mechanical properties and barrier performance of pouches. It is suitable for packaging products such as snacks, frozen foods, and pharmaceuticals.

Considerations for Selecting the Right Material:

Product Compatibility: Choose a material that is compatible with the specific requirements of the packaged product, including its composition, sensitivity to external factors, and shelf life.

Barrier Properties: Consider the desired level of protection against moisture, oxygen, light, and odors to select a material with appropriate barrier properties.

Printing and Branding: Evaluate the printing capabilities and surface finish of the material to ensure it can effectively showcase branding, product information, and graphics.

Environmental Impact: Assess the environmental sustainability of the material, including its recyclability, biodegradability, and overall environmental footprint.

Rinpac also offer top quality flat bottom pouches. Get connected to get a free quote now. Thanks

Design and Customization of Flat Bottom Pouches with Zipper

Flat bottom pouches with zipper closures offer versatile design and customization options, providing ample opportunities for branding and product differentiation. Here are some key aspects of design and customization:

1. Branding Opportunities:

Logo Placement: The front surface of flat bottom pouches provides a prominent space for displaying brand logos, slogans, and graphics, effectively communicating brand identity and values to consumers.

Color Selection: Choose colors that reflect your brand’s aesthetic and resonate with your target audience. Vibrant and eye-catching color schemes can enhance shelf presence and attract consumer attention.

Font Styles: Select legible and visually appealing font styles for text elements such as product names, descriptions, and call-to-action statements. Consistent typography reinforces brand recognition and reinforces brand messaging.

2. Customization Options:

Size and Shape: Flat bottom pouches with zipper closures are available in various sizes and shapes to accommodate different product volumes and packaging requirements. Custom sizing allows for precise fitment of products and maximizes shelf space utilization.

Window Inserts: Incorporate clear window inserts into the pouch design to showcase the packaged product, allowing consumers to see the contents while preserving product freshness and integrity.

Special Finishes: Add special finishes such as matte or glossy coatings, embossing, or metallic accents to enhance visual appeal and tactile experience. These finishes can elevate the perceived value of the product and differentiate it from competitors.

Additional Features: Explore additional features such as tear notches, hang holes, or spouts to enhance functionality and convenience for consumers. These features improve ease of use and contribute to overall consumer satisfaction.

Sustainability of Flat Bottom Pouches with Zipper

In response to growing environmental concerns, the packaging industry is increasingly prioritizing sustainability. Flat bottom pouches with zipper closures can be made more eco-friendly through the use of sustainable materials and recycling options. Here’s how:

1. Eco-Friendly Materials:

Biodegradable Options: Manufacturers can opt for biodegradable materials such as bio-based plastics or compostable films to reduce the environmental impact of flat bottom pouches. These materials break down naturally over time, minimizing pollution and waste accumulation.

Recycled Content: Utilizing recycled materials in pouch production helps reduce the demand for virgin resources and encourages the circular economy. Recycled plastics, paper, and aluminum can be incorporated into pouch construction to lessen environmental strain.

Plant-Based Alternatives: Plant-based materials such as PLA (polylactic acid) derived from renewable sources like corn starch offer a sustainable alternative to traditional petroleum-based plastics. These materials are compostable and reduce reliance on fossil fuels.

2. Recycling Options:

Recyclability: Designing pouches for recyclability ensures they can be easily sorted, collected, and processed in existing recycling streams. Clear labeling and standardized materials facilitate recycling efforts and promote consumer participation.

Collaborative Initiatives: Industry partnerships and collaborations can drive innovation in recycling technologies and infrastructure. Participating in recycling programs and supporting extended producer responsibility (EPR) schemes can enhance recycling rates and reduce environmental impact.

Consumer Education: Educating consumers about the recyclability of flat bottom pouches and providing clear recycling instructions on packaging encourages proper disposal practices. Promoting the benefits of recycling and highlighting the environmental advantages of sustainable packaging fosters eco-conscious consumer behavior.

Manufacturing Process of Flat Bottom Pouches with Zippers

The production of flat bottom pouches with zippers involves several steps to ensure quality, functionality, and efficiency. Here’s an overview of the manufacturing process:

1. Material Selection:

The process begins with selecting suitable materials for the pouch construction, considering factors such as barrier properties, strength, and compatibility with printing and sealing processes. Common materials include laminated films, aluminum foil, and barrier plastics.

2. Printing:

Once the materials are selected, they undergo the printing process to apply graphics, branding, and product information onto the surface of the film. Printing techniques such as flexography, gravure, or digital printing are used to achieve high-quality, vibrant designs.

3. Lamination:

The printed film is then laminated with additional layers, such as barrier films or adhesives, to enhance strength, durability, and barrier properties. Lamination ensures that the pouches maintain product freshness and integrity throughout their lifecycle.

4. Bag Forming:

The laminated film is fed into a bag making machine, where it undergoes a series of folding and sealing operations to form the flat bottom pouch shape. Precision is crucial to ensure consistent dimensions and proper alignment of the pouch components.

5. Bottom Gusset Formation:

To create the flat bottom shape, the bottom gussets of the pouch are formed using specialized equipment. This process involves folding and sealing the film to create a stable base that allows the pouch to stand upright on shelves.

6. Zipper Application:

After forming the pouch shape, the zipper closure is applied to the top of the pouch. The zipper is attached securely using heat sealing or ultrasonic welding techniques, ensuring a reliable and airtight seal for easy opening and resealing.

7. Quality Control:

Throughout the manufacturing process, quality control measures are implemented to inspect the pouches for defects, inconsistencies, and adherence to specifications. This includes visual inspections, seal integrity tests, and dimensional checks to ensure product quality and customer satisfaction.

8. Packaging and Shipping:

Once the pouches are manufactured and inspected, they are packaged into cartons or pallets for shipping to customers or distribution centers. Proper packaging ensures that the pouches are protected during transit and arrive in optimal condition.

Cost Considerations for Flat Bottom Pouches with Zippers

When evaluating the cost of flat bottom pouches with zippers, several factors come into play, impacting the overall pricing and cost-effectiveness of the packaging solution. Here’s a breakdown of key considerations:

1. Material Selection:

The choice of materials significantly influences the cost of flat bottom pouches. High-quality, specialized materials with enhanced barrier properties or sustainable features may come at a higher cost compared to standard options. Factors such as material thickness, recyclability, and availability also affect material costs.

2. Printing Complexity:

The complexity of printing requirements, including the number of colors, graphics, and special finishes, can impact printing costs. Advanced printing techniques and customization options may incur additional charges but contribute to enhanced branding and shelf appeal.

3. Manufacturing Process:

The complexity of the manufacturing process, including bag forming, zipper application, and quality control measures, affects production costs. Efficient production methods and automation can help streamline processes and reduce labor costs, ultimately influencing the overall cost of the pouches.

4. Quantity and Order Size:

Volume discounts and economies of scale apply to packaging production. Ordering larger quantities of flat bottom pouches with zippers typically results in lower unit costs, as fixed costs such as setup and tooling are spread across a higher number of units. However, smaller order sizes may incur higher per-unit costs.

5. Transportation and Logistics:

Shipping and logistics costs associated with transporting pouches from the manufacturing facility to the point of distribution or retail can impact overall costs. Factors such as distance, shipping method, and packaging requirements contribute to transportation expenses.

Cost Comparison with Other Packaging Options:

Flat bottom pouches with zippers offer cost advantages compared to traditional packaging options such as rigid containers or glass jars in several ways:

Material Efficiency: Pouch packaging requires less material compared to rigid containers, resulting in lower material costs and reduced shipping weight.

Storage Space: Pouches are lightweight and flexible, requiring less storage space compared to bulky containers, which can lead to cost savings in warehousing and distribution.

Shipping Costs: The lightweight nature of pouches reduces shipping costs compared to heavier packaging options, especially for long-distance transportation.

Customization: Pouches offer customizable printing options at a lower cost compared to embossing or labeling rigid containers, allowing for branding and product differentiation without significant additional expenses.

Market Trends and Growth of Flat Bottom Pouches with Zippers

Flat bottom pouches with zippers have witnessed a surge in popularity in recent years, driven by changing consumer preferences, industry innovations, and market trends. Here are some key factors contributing to the growth of this packaging format and its future prospects:

1. Consumer Demand for Convenience:

Consumers increasingly seek convenient and practical packaging solutions that offer ease of use, portability, and resealability. Flat bottom pouches with zippers cater to these preferences, providing hassle-free storage, transportation, and consumption experiences for a wide range of products.

2. Retail Shelf Appeal:

The sleek and modern design of flat bottom pouches with zippers enhances product visibility and shelf presence, making them stand out on crowded retail shelves. Brands leverage eye-catching graphics, vibrant colors, and customizable printing options to attract consumer attention and drive purchase decisions.

3. Sustainability Initiatives:

Growing environmental awareness has led to a shift towards sustainable packaging solutions. Flat bottom pouches with zippers offer eco-friendly options, such as recyclable materials, compostable films, and reduced material usage compared to traditional packaging formats. Brands that prioritize sustainability benefit from enhanced brand reputation and consumer loyalty.

4. Versatility Across Industries:

Flat bottom pouches with zippers find applications across various industries, including food and beverage, pet care, household products, pharmaceuticals, and personal care. Their adaptability to different product types, sizes, and storage requirements makes them a preferred packaging choice for a diverse range of products.

5. Technological Advancements:

Advancements in packaging technology and machinery have improved the efficiency, quality, and customization capabilities of flat bottom pouch production. Innovations in printing techniques, barrier materials, and zipper closures enable manufacturers to meet evolving consumer demands and industry standards.

Future Prospects:

The future outlook for flat bottom pouches with zippers remains promising, driven by ongoing advancements in packaging materials, design innovations, and sustainability initiatives. Key trends shaping the future of this packaging format include:

Smart Packaging: Integration of smart features such as QR codes, NFC tags, and interactive packaging elements to enhance consumer engagement and product traceability.

Personalization: Customized packaging solutions tailored to specific consumer preferences, demographics, and market segments to drive brand differentiation and consumer loyalty.

Circular Economy: Emphasis on closed-loop recycling systems, renewable materials, and waste reduction strategies to minimize environmental impact and promote a circular economy approach to packaging.

Maintenance and Handling of Flat Bottom Pouches with Zippers

Proper storage and handling practices are essential for maintaining the quality, integrity, and functionality of flat bottom pouches with zippers. Here are some tips to ensure effective maintenance and handling:

1. Storage Conditions:

Avoid Direct Sunlight: Store flat bottom pouches in a cool, dry place away from direct sunlight and heat sources. Exposure to UV radiation and high temperatures can degrade the packaging material and compromise product quality.

Optimal Temperature: Maintain storage temperatures within the recommended range specified by the packaging manufacturer. Extreme temperatures can affect the integrity of the pouch material and seal, leading to potential leakage or spoilage of the packaged contents.

Humidity Control: Prevent moisture ingress by storing pouches in low humidity environments. Excessive moisture can cause condensation inside the pouches, affecting product freshness and shelf life.

2. Handling Guidelines:

Avoid Sharp Objects: Handle flat bottom pouches with care to prevent punctures or tears in the packaging material. Avoid contact with sharp objects or abrasive surfaces that could damage the pouches and compromise their protective barrier.

Use Proper Lifting Techniques: When transporting or stacking pouches, use proper lifting techniques to avoid overloading or causing damage to the packaging. Support the bottom of the pouches to distribute weight evenly and prevent distortion or deformation.

Mindful Opening and Closing: When opening and closing the zipper closure, ensure proper alignment and gentle handling to prevent damage to the zipper tracks or sealing area. Avoid excessive force or rough handling that could compromise the integrity of the seal.

3. Regular Inspection:

Visual Checks: Periodically inspect flat bottom pouches for signs of damage, wear, or deterioration. Look for any visible tears, leaks, or compromised seals that may indicate packaging defects or storage issues.

Seal Integrity: Check the integrity of the zipper closure and heat seals to ensure airtight and leak-proof packaging. Perform seal integrity tests or leak detection methods as part of quality assurance protocols to identify any potential issues early on.

Conclusion

In conclusion, flat bottom pouches with zippers offer a versatile and efficient packaging solution for a wide range of products across industries. With their sleek design, convenient features, and customizable options, these pouches cater to evolving consumer preferences and industry trends. From food and beverage packaging to pharmaceuticals and personal care products, flat bottom pouches with zippers provide optimal protection, shelf appeal, and sustainability benefits.

As market demand continues to grow, driven by factors such as convenience, sustainability, and technological advancements, the future prospects for flat bottom pouches remain promising. By embracing innovation, adopting sustainable practices, and prioritizing consumer needs, businesses can capitalize on the opportunities presented by this packaging format and drive growth in the packaging industry.

In summary, flat bottom pouches with zippers represent a modern and efficient packaging solution that meets the demands of today’s consumers and businesses. By leveraging their benefits and staying attuned to market trends, companies can enhance brand recognition, improve product differentiation, and contribute to a more sustainable future.

Rinpac offer top quality bags and pouches. Contact us today. Thanks

FAQs

What is the difference between a flat pouch and a stand-up pouch?

A flat pouch lies flat and typically does not have a gusset, while a stand-up pouch has a gusseted bottom that allows it to stand upright on its own.

What is a flat bottom pouch?

A flat bottom pouch is a type of flexible packaging with a flat bottom gusset, providing stability and space for product display.

What are zipper pouches used for?

Zipper pouches are commonly used for storing and organizing small items such as cosmetics, toiletries, stationery, snacks, or travel essentials. They provide easy access and secure closure with a zipper mechanism.

What do you put in a small zipper pouch?

Small zipper pouches are versatile and can be used to store various items such as coins, keys, earphones, USB drives, makeup, medication, or first aid supplies.

Is a quad seal bag better than a flat bottom bag?

The superiority of a quad seal bag or a flat bottom bag depends on the specific needs of the product and the preferences of the manufacturer. Quad seal bags offer versatility, while flat bottom bags provide stability and aesthetic appeal.

What is a Japanese pouch?

A Japanese pouch, also known as a furoshiki, is a traditional Japanese wrapping cloth used to carry and wrap items, often as an eco-friendly alternative to disposable packaging.

What do you call a plastic bag with a zipper?

A plastic bag with a zipper closure is commonly referred to as a zipper pouch or a resealable bag.

What is a stand-up zipper pouch?

A stand-up zipper pouch is a type of flexible packaging with a gusseted bottom that allows it to stand upright on its own, combined with a zipper closure for easy opening and resealing.

What is the point of a double zipper?

A double zipper provides additional versatility and convenience by allowing the pouch to be opened and closed from either end. It offers more control over the opening size and direction of access to the contents.

What is a K seal bag?

A K seal bag is a type of flexible packaging with side seals that form a “K” shape when viewed from the top, providing extra strength and stability to the package.

What is a star seal bottom bag?

A star seal bottom bag is a type of plastic bag with a unique sealed bottom that forms a star-like pattern when viewed from the outside. This design helps to evenly distribute the weight of the contents and prevents leaks.

What is a pinch bottom bag?

A pinch bottom bag is a type of paper bag with a folded and pinched bottom closure, typically used for packaging dry goods such as flour, sugar, or grains.

What is a kissing zipper?

A kissing zipper refers to two zipper tracks that meet or nearly meet in the middle when closed, resembling a “kiss.” This design is commonly used in double-slider zippers for bags and jackets.

Why do you put a zipper on the bottom of your pants?

A zipper on the bottom of pants, often called ankle zippers or leg zippers, allows for easy adjustment of the pant leg opening. It can facilitate putting on and taking off the pants, as well as provide ventilation or accommodate wearing over boots.

What is a reverse zipper?

A reverse zipper, also known as an inverted zipper, is a zipper that opens and closes in the opposite direction compared to a standard zipper. This design is sometimes used for aesthetic purposes or for added security.