Home » Bags & Pouches » Flat Bottom Pouches » 250g Flat Bottom Pouch

250g Flat Bottom Pouch

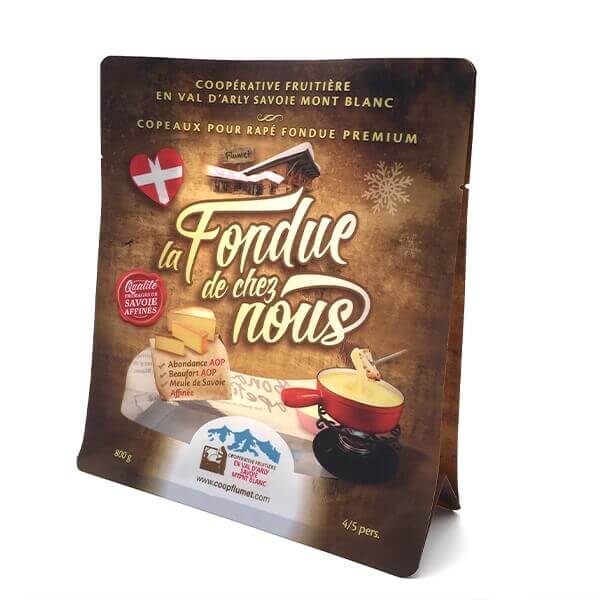

250g flat bottom pouches are pouches with the completely flat bottom, also called box pouches or quad seal pouches allow specialty food creators to proudly display their brands on store shelves.

Please note that we have a MOQ for our pouch. For pouches in stock, the MOQ is 500 pcs. For customized pouches, please see the MOQ as followed:

1, Digital Printing — 500 pcs

2, Gravure Printing — 5,000pcs

Rinpac assists you throughout your project: bag shape, material, thickness, capacity and printing options. Please contact us or mark your requirements on the inquiry quotation.

Order single or thousands of items at a time. Our warehouse and flexible shipping options are available for last-minute, deadline critical orders.

- Free Sample

*Customization is always available, please mark down your need in cart or just contact us.

Specification of 250g Flat Bottom Pouch

| Materials | Per customer’s packaging needs. Using materials such as clear poly, metalized films, foil laminations and kraft paper. All pouches are made of food grade solvent free packaging materials. |

| Sizes | Per customers’ needs. |

| Styles | Quad sealed flat bottom |

| Resealable Features | Press-to-close zippers: Economical and commonly used |

| Tin Ties: Available in Plastic and Kraft | |

| Additional Features | Tear notches |

| Degassing Valves | |

| Knocked out windows providing a sneak peek of what’s inside: clear window, frosted window, or matte finish with glossy clear window | |

| Laser scoring or laser perforation | |

| Printing | Glossy printing |

| Matte finish printing | |

| Glossy printing with spot matte finishes | |

| Per customer’s design and requirements. | |

| Accessories | Zipper for reclosure |

| Tin Tie for reclosure | |

| Degassing Valve |

Request A Quote - 250g Flat Bottom Pouch

Need something helped in a short time? We’ve got a plan for you.

Introduction to 250g Flat Bottom Pouch

In today’s dynamic market landscape, packaging plays a pivotal role in shaping consumer perceptions and driving purchasing decisions. Among the myriad packaging options available, 250g Flat Bottom Pouches stand out as a versatile and innovative solution. In this comprehensive guide, we delve into the intricacies of these pouches, exploring their features, benefits, applications, and more.

What are 250g Flat Bottom Pouches?

Definition and Design

250g Flat Bottom Pouches, as the name suggests, are pouches designed with a flat bottom base that provides stability and support, ensuring the pouch stands upright on shelves. This unique design eliminates the need for additional packaging support, such as boxes or trays, making it a cost-effective and space-efficient solution.

Features and Construction

Crafted from high-quality materials such as aluminum foil or multilayer laminates, 250g Flat Bottom Pouches offer superior barrier properties, protecting contents from moisture, oxygen, light, and external contaminants. The flat bottom design maximizes storage capacity, allowing for efficient packing and stacking of products. Additionally, these pouches often feature resealable zip closures for added convenience and freshness preservation.

Applications of 250g Flat Bottom Pouches

Food Packaging

250g Flat Bottom Pouches are widely used in the food industry for packaging various products such as coffee, snacks, nuts, dried fruits, granola, and more. Their airtight seal and protective barrier properties make them ideal for preserving the flavor, aroma, and freshness of food items.

Pet Food Packaging

The durability and resilience of 250g Flat Bottom Pouches make them suitable for packaging pet food and treats. Their resealable closures ensure convenient storage and dispensing, while their flat bottom design allows for easy stacking and display on retail shelves.

Pharmaceutical Packaging

In the pharmaceutical industry, 250g Flat Bottom Pouches are utilized for packaging powdered supplements, vitamins, nutraceuticals, and pharmaceutical powders. Their tamper-evident closures and protective barrier properties ensure product safety and integrity throughout the supply chain.

Rinpac offers top quality block bottom bags. Get a free quote now. Thanks

Uniqueness of 250g Flat Bottom Pouches

In the realm of packaging solutions, standing out from the crowd is essential to capture consumer attention and drive sales. 250g Flat Bottom Pouches offer a unique set of features and advantages that set them apart from traditional packaging formats. Let’s explore what makes these pouches truly unique:

1. Innovative Design

At the core of their uniqueness lies the innovative design of 250g Flat Bottom Pouches. Unlike conventional pouches or bags, these pouches are crafted with a flat bottom base, providing unmatched stability and support. This design not only ensures the pouches stand upright on shelves but also eliminates the need for additional packaging support, such as boxes or trays. The result? A sleek and professional presentation that grabs consumer attention and elevates brand perception.

2. Superior Barrier Properties

Another distinguishing feature of 250g Flat Bottom Pouches is their superior barrier properties. Crafted from high-quality materials such as aluminum foil or multilayer laminates, these pouches offer unparalleled protection against external elements. From moisture and oxygen to light and contaminants, these pouches create a protective shield around the packaged contents, ensuring long-lasting freshness and quality.

3. Space-Efficient Storage

Efficient space utilization is a hallmark of 250g Flat Bottom Pouches. Their flat bottom design maximizes storage capacity while minimizing the footprint, making them ideal for businesses looking to optimize shelf space and storage efficiency. Whether stacked on retail shelves or stored in warehouses, these pouches make the most of available space, reducing storage costs and enhancing operational efficiency.

4. Versatility Across Industries

From the food industry to pet care and pharmaceuticals, 250g Flat Bottom Pouches find applications across a wide range of industries. Their versatility and adaptability make them suitable for packaging various products, including coffee, snacks, pet food, supplements, and more. Whether used for retail packaging or bulk storage, these pouches offer unmatched flexibility and performance in diverse settings.

5. Eco-Friendly Options

In response to growing environmental concerns, many manufacturers now offer eco-friendly versions of 250g Flat Bottom Pouches. These pouches are crafted from sustainable materials and feature recyclable or compostable options, reducing environmental impact and aligning with eco-conscious consumer preferences. By choosing eco-friendly pouches, businesses can demonstrate their commitment to sustainability and appeal to environmentally conscious consumers.

In essence, what makes 250g Flat Bottom Pouches truly unique is their combination of innovative design, superior barrier properties, space-efficient storage, versatility across industries, and eco-friendly options. As businesses strive to differentiate themselves in the competitive market landscape, these pouches emerge as a standout packaging solution that delivers both practicality and performance.

Advantages of Using 250g Flat Bottom Pouches

In today’s competitive market landscape, packaging plays a pivotal role in shaping consumer perceptions and driving purchasing decisions. 250g Flat Bottom Pouches offer a multitude of advantages that make them a preferred choice for businesses across various industries. Let’s explore some of the key benefits:

1. Increased Shelf Presence

One of the primary advantages of 250g Flat Bottom Pouches is their ability to enhance shelf presence. The sleek and professional appearance of these pouches grabs consumer attention and stands out on crowded retail shelves. Their flat bottom design ensures stability and prevents tipping or collapsing, allowing products to remain prominently displayed, even in high-traffic areas of stores.

2. Enhanced Stability

Stability is paramount when it comes to packaging, especially for products that need to stand upright on shelves. 250g Flat Bottom Pouches excel in this aspect, thanks to their innovative design with a flat bottom base. Unlike traditional pouches or bags that may sag or topple over, these pouches provide reliable support, ensuring products remain upright and well-presented at all times.

3. Improved Brand Visibility

The packaging is often the first point of contact between a brand and its customers. With 250g Flat Bottom Pouches, businesses have the opportunity to showcase their brand identity and create a lasting impression. These pouches offer ample space for branding elements such as logos, graphics, and product information, allowing brands to communicate their message effectively and stand out from competitors.

4. Versatility in Design and Functionality

Another advantage of 250g Flat Bottom Pouches is their versatility in design and functionality. Whether used for packaging coffee, snacks, pet food, or pharmaceuticals, these pouches can be customized to meet specific product requirements and consumer preferences. From resealable zip closures to clear window panels, businesses have the flexibility to tailor the pouches to their unique needs, enhancing convenience and user experience.

5. Cost-Effective Packaging Solution

In addition to their aesthetic appeal and functional benefits, 250g Flat Bottom Pouches offer cost-effective packaging solutions for businesses. Their lightweight and flexible construction reduces packaging material and transportation costs, while their space-efficient design optimizes shelf space and storage capacity. By streamlining packaging processes and minimizing waste, businesses can achieve cost savings without compromising on quality or performance.

Design and Structure of 250g Flat Bottom Pouches

Materials Used

The design and structure of 250g Flat Bottom Pouches are engineered to provide optimal functionality and performance while ensuring product freshness and protection. These pouches are typically constructed using high-quality materials known for their durability, barrier properties, and versatility. Common materials used in the manufacturing of 250g Flat Bottom Pouches include:

Aluminum Foil: Known for its excellent barrier properties, aluminum foil is often used as a primary material in 250g Flat Bottom Pouches. It provides an effective barrier against moisture, oxygen, light, and external contaminants, preserving the freshness and quality of packaged products.

Multilayer Laminates: Multilayer laminates consist of multiple layers of different materials, each serving a specific purpose. These laminates may include materials such as polyester, polyethylene, nylon, and aluminum foil, combined to create a barrier that offers protection against external elements while maintaining product integrity.

Features

The design features of 250g Flat Bottom Pouches are tailored to meet the needs of various industries and applications. These pouches boast several key features that enhance functionality, convenience, and user experience. Some of the notable features include:

Flat Bottom Design: The defining feature of 250g Flat Bottom Pouches is their flat bottom base, which provides stability and support, allowing the pouches to stand upright on shelves. This design eliminates the need for additional packaging support, such as boxes or trays, making the pouches space-efficient and visually appealing.

Resealable Zip Closures: Many 250g Flat Bottom Pouches are equipped with resealable zip closures, allowing consumers to open and close the pouches multiple times while maintaining product freshness and integrity. The zip closures provide convenience and ease of use, allowing for effortless storage and portion control.

Clear Window Panels: Some 250g Flat Bottom Pouches feature clear window panels that offer visibility of the packaged contents, allowing consumers to see the product inside without having to open the pouch. This feature enhances product presentation and allows brands to showcase their products effectively, enticing consumers with visual appeal.

Tear Notches: Tear notches are small perforations located at the top of the pouch, facilitating easy opening by allowing consumers to tear the top of the pouch along a predetermined line. This feature enhances convenience and accessibility, making it effortless for consumers to access the packaged products.

Durability and Performance

In addition to their design features, 250g Flat Bottom Pouches are known for their durability and performance. These pouches are designed to withstand the rigors of handling, transportation, and storage, ensuring that the packaged products remain protected throughout the supply chain. Whether used for packaging coffee, snacks, pet food, or pharmaceuticals, 250g Flat Bottom Pouches deliver consistent performance and reliability, earning them a reputation as a trusted packaging solution in various industries.

Get top quality flat bottom pouches from Rinpac. Get a free quote now. Thanks

Cost-effectiveness of 250g Flat Bottom Pouches

Efficient Material Usage

250g Flat Bottom Pouches are renowned for their efficient utilization of materials, which contributes significantly to their cost-effectiveness. Unlike traditional rigid packaging options, such as glass jars or bottles, flat bottom pouches require minimal material for production. The streamlined design eliminates the need for additional components like caps or closures, reducing both material costs and waste.

Lightweight Construction

Another factor that enhances the cost-effectiveness of 250g Flat Bottom Pouches is their lightweight construction. Crafted from flexible materials like laminates or films, these pouches are significantly lighter than their rigid counterparts. This lightweight design translates to lower shipping costs, as less fuel is required to transport the pouches. Additionally, reduced shipping weight contributes to a smaller carbon footprint, aligning with sustainability goals while saving on transportation expenses.

Efficient Storage

The space-efficient nature of 250g Flat Bottom Pouches further underscores their cost-effectiveness. Their flexible structure allows them to be stored compactly, maximizing storage capacity in warehouses, distribution centers, and retail spaces. By optimizing storage efficiency, businesses can minimize storage costs and improve overall operational efficiency, leading to significant savings over time.

Customization Options

Despite their economical design, 250g Flat Bottom Pouches offer a range of customization options to suit diverse branding needs. From custom printing to specialized finishes, businesses can personalize pouch designs to enhance product visibility and brand recognition. While customization may entail additional upfront costs, the potential for increased consumer engagement and sales can outweigh these expenses, making it a cost-effective investment in the long run.

Long-term Benefits

In addition to their immediate cost savings, 250g Flat Bottom Pouches offer long-term benefits that contribute to their overall cost-effectiveness. Their durable construction and protective barrier properties help extend the shelf life of packaged products, reducing the risk of spoilage or damage. This can lead to fewer product losses and lower replacement costs, further bolstering the pouches’ cost-effectiveness over time.

Customization Options for 250g Flat Bottom Pouches

Printing Techniques

When it comes to customizing 250g Flat Bottom Pouches, businesses have a wide array of printing techniques at their disposal to create eye-catching designs and convey brand messaging effectively.

Flexographic Printing: Flexographic printing is a popular choice for printing high-quality, cost-effective designs on flat bottom pouches. This technique utilizes flexible relief plates to transfer ink onto the pouch surface, allowing for crisp and vibrant graphics.

Rotogravure Printing: Rotogravure printing, also known as gravure printing, is ideal for achieving intricate designs and photorealistic images on flat bottom pouches. This process involves etching the design onto a cylinder, which is then coated with ink and pressed onto the pouch surface, resulting in stunning, detailed prints.

Digital Printing: Digital printing offers versatility and quick turnaround times for customizing flat bottom pouches. This technique utilizes digital files to directly apply ink onto the pouch surface, making it suitable for short print runs and variable data printing.

Add-ons

In addition to printing techniques, businesses can enhance the visual appeal and functionality of 250g Flat Bottom Pouches through various add-ons and finishing options:

Matte or Glossy Finishes: Matte and glossy finishes add texture and shine to flat bottom pouches, elevating their appearance and enhancing shelf appeal. Businesses can choose between a matte finish for a soft, luxurious look or a glossy finish for a sleek and polished appearance.

Spot Varnishing: Spot varnishing involves applying a clear coating to specific areas of the pouch, such as logos or graphics, to create contrast and visual interest. This technique adds a tactile element to the design, making certain elements stand out and catch the eye.

Embossing or Debossing: Embossing and debossing techniques create raised or recessed impressions on the pouch surface, adding depth and dimension to the design. Businesses can use these techniques to create tactile logos or text that enhances brand recognition and consumer engagement.

Zipper Closures or Tear Notches: For added functionality, businesses can incorporate zipper closures or tear notches into their flat bottom pouch designs. Zipper closures allow for convenient resealing of the pouch, while tear notches facilitate easy opening, improving user experience and product accessibility.

By leveraging these customization options, businesses can create bespoke 250g Flat Bottom Pouches that reflect their brand identity, capture consumer attention, and differentiate their products in the competitive marketplace.

How to Choose the Right 250g Flat Bottom Pouch: Consideration Factors

Selecting the optimal 250g Flat Bottom Pouch for your packaging needs requires careful consideration of various factors to ensure that it aligns with your product requirements, brand image, and budget constraints. Here are key consideration factors to guide your decision-making process:

1. Product Type and Characteristics

Begin by assessing the specific characteristics of your product, including its size, shape, weight, and composition. Consider whether your product is dry, liquid, or semi-liquid, as well as any unique packaging requirements such as barrier properties or oxygen sensitivity. The chosen pouch should accommodate your product comfortably and provide adequate protection during storage and transportation.

2. Material Selection

Evaluate the material options available for 250g Flat Bottom Pouches and choose one that best suits your product and brand objectives. Common materials include polyethylene (PE), polypropylene (PP), polyester (PET), and aluminum foil laminates. Consider factors such as barrier properties, puncture resistance, and sustainability credentials when selecting the material for your pouches.

3. Closure Mechanism

Determine the most suitable closure mechanism for your flat bottom pouches based on your product’s packaging requirements and user convenience. Options may include zipper closures, resealable tapes, or heat-sealed closures. Ensure that the chosen closure mechanism maintains product freshness and prevents leakage or spillage throughout the product’s lifecycle.

4. Customization Options

Explore customization opportunities to tailor the design and branding of your 250g Flat Bottom Pouches to reflect your brand identity and appeal to your target audience. Consider printing techniques, add-ons, and finishing options such as matte or glossy finishes, spot varnishing, and embossing to create visually striking packaging that stands out on retail shelves.

5. Environmental Impact

Incorporate sustainability considerations into your decision-making process by opting for eco-friendly materials and manufacturing processes for your flat bottom pouches. Look for recyclable, compostable, or bio-based materials that align with your brand’s sustainability goals and appeal to environmentally conscious consumers.

6. Cost Considerations

Balance your desired features and customization options with budget constraints to ensure cost-effectiveness. Evaluate the total cost of ownership, including material costs, printing expenses, and any additional customization fees, to determine the most economical solution that meets your packaging requirements without compromising on quality or functionality.

Tips for Effective Utilization of 250g Flat Bottom Pouches

To maximize the benefits of 250g Flat Bottom Pouches and ensure optimal performance throughout their lifecycle, it’s essential to follow best practices for storage and handling. Here are some valuable tips to help you make the most of your pouches:

Proper Storage

Temperature Control: Store flat bottom pouches in a cool, dry environment away from direct sunlight and heat sources to prevent premature degradation of the materials and maintain product freshness.

Avoid Moisture: Keep pouches away from areas prone to moisture, such as kitchens or bathrooms, as excess moisture can compromise the integrity of the packaging and lead to mold or mildew growth.

Stacking: When storing multiple pouches, stack them carefully to avoid crushing or damaging the contents. Ensure that the weight is evenly distributed to prevent deformation or distortion of the pouches.

Vertical Orientation: Store pouches in a vertical position whenever possible to prevent bulging or deformation of the bottom gusset, which can affect the stability and integrity of the pouches.

Handling

Gentle Handling: Handle flat bottom pouches with care to avoid punctures, tears, or creases in the material. Avoid rough handling or excessive force when filling, sealing, or transporting the pouches.

Proper Filling: Fill pouches with the recommended product volume to prevent overfilling, which can strain the seams and compromise the pouch’s integrity. Use filling equipment or funnels to ensure accurate filling and minimize spills or leaks.

Sealing Techniques: Follow proper sealing techniques to ensure a secure closure and maintain product freshness. Apply consistent pressure along the seal to create a tight bond and prevent air or moisture ingress.

Labeling: Clearly label flat bottom pouches with product information, expiration dates, and handling instructions to provide essential information to consumers and facilitate inventory management.

Comparison with Other Packaging Solutions

When evaluating packaging options for your products, it’s essential to consider how 250g Flat Bottom Pouches stack up against other packaging solutions in terms of performance, versatility, and cost-effectiveness. Let’s explore how flat bottom pouches compare to alternative packaging solutions:

Flexible Packaging vs. Rigid Packaging

Flexibility and Versatility

250g Flat Bottom Pouches offer unparalleled flexibility and versatility compared to rigid packaging options such as glass jars, bottles, or cans. Their pliable structure allows them to conform to the shape of the packaged product, making them suitable for a wide range of products, including dry goods, snacks, pet food, and household items. In contrast, rigid packaging solutions are often limited in terms of shape and size, restricting their applicability to specific product types.

Space Efficiency

Flat bottom pouches excel in space efficiency, requiring minimal storage space when empty and maximizing shelf space when filled. Their lightweight construction and collapsible design make them ideal for shipping and storage, reducing transportation costs and storage footprint compared to bulky rigid containers.

Environmental Impact

From an environmental standpoint, flat bottom pouches have a lower environmental footprint compared to rigid packaging options. They typically use fewer materials during production, resulting in reduced packaging waste and lower transportation emissions due to their lightweight design. Additionally, many flat bottom pouches are made from recyclable or compostable materials, offering a more sustainable packaging solution compared to non-recyclable rigid containers.

Barrier Properties and Product Protection

Preservation of Freshness

One of the key advantages of 250g Flat Bottom Pouches is their excellent barrier properties, which help preserve the freshness and quality of packaged products. These pouches can be customized with multiple layers of materials, including aluminum foil, to provide optimal protection against moisture, oxygen, light, and odor infiltration, extending the shelf life of perishable goods.

Fragility and Breakage

While rigid packaging solutions may offer superior protection against physical damage and breakage, they are also more prone to shattering or cracking during handling and transportation. Flat bottom pouches, on the other hand, are more resilient and less susceptible to damage, making them a safer and more reliable option for shipping and storage.

Cost Considerations

Production Costs

In terms of production costs, 250g Flat Bottom Pouches often offer significant cost savings compared to rigid packaging alternatives. Their lightweight construction and efficient material usage result in lower manufacturing and material costs, making them a cost-effective choice for businesses looking to optimize their packaging expenses.

Transportation Costs

Flat bottom pouches also offer cost advantages when it comes to transportation. Their lightweight design reduces shipping weight and volume, resulting in lower freight costs compared to heavier rigid containers. Additionally, the collapsible nature of flat bottom pouches allows for more efficient palletization and storage, further reducing transportation expenses.

Conclusion

In conclusion, 250g Flat Bottom Pouches emerge as a versatile, practical, and cost-effective packaging solution that meets the diverse needs of modern businesses. With their innovative design, superior barrier properties, and customizable features, flat bottom pouches offer numerous advantages over traditional rigid packaging options.

From enhanced shelf presence and product protection to eco-friendly materials and space-efficient storage, flat bottom pouches excel on multiple fronts, making them the packaging solution of choice for a wide range of industries, including food and beverage, pet care, pharmaceuticals, and more.

By leveraging the benefits of 250g Flat Bottom Pouches, businesses can elevate their brand image, improve product visibility, and reduce packaging waste, ultimately driving greater customer satisfaction and loyalty.

As you consider your packaging options, remember to weigh the unique advantages of flat bottom pouches against other packaging solutions to make an informed decision that aligns with your product requirements, brand values, and budget considerations.

Choose flat bottom pouches for packaging that not only protects your products but also enhances their appeal and sustainability, setting your business apart in the competitive marketplace.

Rinpac offers top quality bags and pouches. Contact us today. Thanks

FAQs

What are the dimensions of a 250g stand up pouch?

The dimensions of a 250g stand-up pouch can vary depending on the specific design and manufacturer. However, common dimensions for such a pouch might be around 5 inches in width by 8 inches in height with a depth of approximately 2 inches.

What is a flat bottom pouch?

A flat bottom pouch is a type of flexible packaging characterized by its rectangular bottom that provides stability and allows the pouch to stand upright on its own. It is commonly used for packaging various products such as coffee, snacks, and pet food.

What size is a 100 grams stand up pouch?

The size of a 100g stand-up pouch can vary based on the specific design and manufacturer. However, a typical size for such a pouch might be around 4 inches in width by 6 inches in height with a depth of approximately 1.5 inches.

What is the use of flat pouch?

Flat pouches are versatile packaging solutions used for a wide range of products including food items like snacks, confectionery, and dried fruits, as well as non-food items like pharmaceuticals, cosmetics, and industrial components. They provide a sleek and convenient packaging option for both retail and wholesale applications.

What is the size of 200gm pouch?

The size of a 200g pouch can vary depending on the specific product requirements and manufacturer specifications. However, a common size for such a pouch might be around 5 inches in width by 7 inches in height with a depth of approximately 1.5 inches.

What is pouch measurement?

Pouch measurement refers to the dimensions and specifications of a pouch, including its width, height, depth, and any other relevant measurements such as the sealing area or volume capacity. These measurements are crucial for determining the suitability of the pouch for a particular product and packaging application.

What is the difference between a flat pouch and a stand-up pouch?

The main difference between a flat pouch and a stand-up pouch lies in their bottom design. Flat pouches have a sealed bottom and lay flat when filled, whereas stand-up pouches have a gusseted bottom that allows them to stand upright on their own, providing better visibility and shelf presence.

How do you size a stand-up pouch?

To size a stand-up pouch, you typically measure its width, height, and depth. The width is the distance across the front of the pouch, the height is the distance from the bottom seal to the top seal, and the depth is the measurement from the front to the back of the pouch. These dimensions help determine the pouch’s capacity and suitability for specific products.

What is the size of 1 kg pouch in inches?

The size of a 1 kg pouch can vary depending on the product being packaged and the specific requirements of the manufacturer. However, a rough estimate for such a pouch might be around 8 inches in width by 12 inches in height with a depth of approximately 3 inches.

What is the size of 1kg stand up pouch?

The size of a 1 kg stand-up pouch can vary based on the specific design and manufacturer. However, common dimensions for such a pouch might be around 8 inches in width by 12 inches in height with a depth of approximately 3 inches.