Home » Bags & Pouches » Flat Bottom Pouches » Standing Pouch Flat Bottom

Standing Pouch Flat Bottom

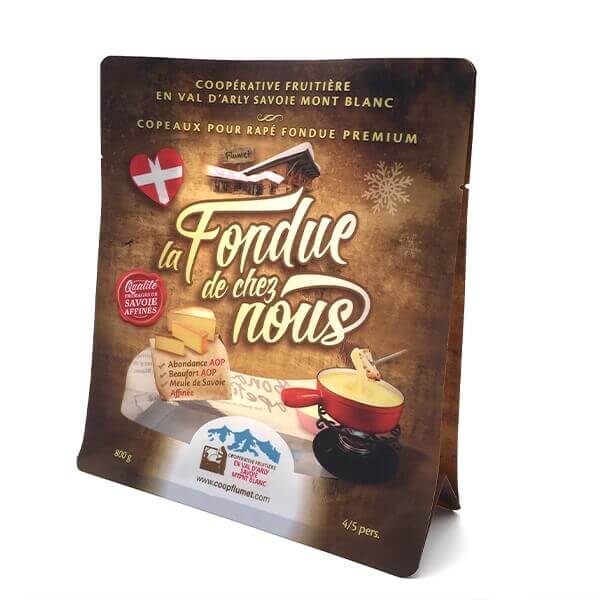

Standing pouches flat bottom are pouches with the completely flat bottom, also called box pouches or quad seal pouches allow specialty food creators to proudly display their brands on store shelves.

Please note that we have a MOQ for our pouch. For pouches in stock, the MOQ is 500 pcs. For customized pouches, please see the MOQ as followed:

1, Digital Printing — 500 pcs

2, Gravure Printing — 5,000pcs

Rinpac assists you throughout your project: bag shape, material, thickness, capacity and printing options. Please contact us or mark your requirements on the inquiry quotation.

Order single or thousands of items at a time. Our warehouse and flexible shipping options are available for last-minute, deadline critical orders.

- Free Sample

*Customization is always available, please mark down your need in cart or just contact us.

Specification of Flat Bottom Stand Up Pouches

| Materials | Per customer’s packaging needs. Using materials such as clear poly, metalized films, foil laminations and kraft paper. All pouches are made of food grade solvent free packaging materials. |

| Sizes | Per customers’ needs. |

| Styles | Quad sealed flat bottom |

| Resealable Features | Press-to-close zippers: Economical and commonly used |

| Tin Ties: Available in Plastic and Kraft | |

| Additional Features | Tear notches |

| Degassing Valves | |

| Knocked out windows providing a sneak peek of what’s inside: clear window, frosted window, or matte finish with glossy clear window | |

| Laser scoring or laser perforation | |

| Printing | Glossy printing |

| Matte finish printing | |

| Glossy printing with spot matte finishes | |

| Per customer’s design and requirements. | |

| Accessories | Zipper for reclosure |

| Tin Tie for reclosure | |

| Degassing Valve |

Request A Quote - Flat Bottom Stand Up Pouches

Need something helped in a short time? We’ve got a plan for you.

Related Products - Flat Bottom Stand Up Pouches

Introduction to Flat Bottom Stand Up Pouches

Flat bottom stand up pouches are innovative packaging solutions designed to combine the stability of a flat bottom with the convenience of a stand-up pouch. These pouches feature a unique flat bottom design that allows them to stand upright on store shelves, countertops, or display racks, making them highly versatile for packaging various products.

Definition:

Flat bottom stand up pouches, also known as box pouches or block bottom pouches, are flexible packaging containers with a flat base and gusseted sides that expand when filled with product. They typically feature a resealable zipper closure and are made from high-quality materials such as laminated films or barrier films to provide excellent protection and preservation for packaged goods.

Purpose:

The primary purpose of flat bottom stand up pouches is to provide a visually appealing and functional packaging solution for a wide range of products, including snacks, pet food, coffee, tea, nuts, grains, confectionery, and more. These pouches offer several key benefits:

Enhanced Shelf Presence: The flat bottom design allows the pouches to stand upright on store shelves, maximizing product visibility and attracting consumer attention with their sleek and professional appearance.

Increased Stability: Unlike traditional stand-up pouches, which can sometimes tip over when placed on flat surfaces, flat bottom stand up pouches offer superior stability and balance, ensuring that the contents remain upright and secure during storage, transportation, and display.

Space-saving Design: The compact and stackable nature of flat bottom stand up pouches makes them ideal for efficient storage and transportation, minimizing space requirements and reducing packaging waste.

Extended Shelf Life: Flat bottom stand up pouches are often equipped with high barrier properties to protect the contents from moisture, oxygen, light, and other external factors that can compromise product freshness and quality, thereby extending shelf life and preserving product integrity.

Convenient Resealability: Many flat bottom stand up pouches feature a resealable zipper closure or tear notch for easy opening and reclosing, allowing consumers to conveniently access the contents multiple times while keeping them fresh and secure.

Advantages of Flat Bottom Stand Up Pouches

Flat bottom stand up pouches offer several key advantages over traditional packaging options, making them a popular choice for manufacturers and consumers alike. Here are some of the main benefits:

1. Shelf Presence:

Flat bottom stand up pouches provide superior shelf presence compared to other packaging formats. Their unique flat base and upright stance ensure maximum visibility on store shelves, allowing products to stand out and attract the attention of consumers. The sleek and professional appearance of these pouches enhances brand image and encourages impulse purchases.

2. Space Utilization:

One of the significant advantages of flat bottom stand up pouches is their efficient use of space. The flat base and gusseted sides allow the pouches to stand upright without the need for additional support, maximizing the use of shelf space and optimizing product display. This space-saving design is particularly beneficial for retailers with limited shelf space or those looking to maximize product assortment.

3. Durability:

Flat bottom stand up pouches are constructed from high-quality materials such as laminated films or barrier films, which offer excellent durability and protection for packaged goods. These pouches are resistant to punctures, tears, and leaks, ensuring that products remain intact and secure during handling, transportation, and storage. Additionally, their robust construction helps prevent damage or spoilage, resulting in reduced product loss and improved customer satisfaction.

4. Extended Shelf Life:

Many flat bottom stand up pouches are equipped with advanced barrier properties that provide superior protection against moisture, oxygen, light, and other environmental factors. This extended shelf life helps preserve the freshness, flavor, and quality of packaged products for longer periods, reducing the need for preservatives and additives. As a result, manufacturers can offer products with longer shelf lives, while consumers can enjoy fresher and more flavorful products.

5. Eco-Friendly:

Flat bottom stand up pouches are often made from lightweight and recyclable materials, making them an eco-friendly packaging option compared to traditional rigid containers or bottles. Additionally, their compact and lightweight design reduces packaging waste and transportation costs, contributing to environmental sustainability and reducing carbon footprint.

Materials Used in Flat Bottom Stand Up Pouches

Flat bottom stand up pouches are available in a variety of materials, each offering unique properties and benefits to suit different packaging needs. Here are some common materials used in the manufacturing of flat bottom stand up pouches:

1. Plastic:

Plastic is one of the most commonly used materials for flat bottom stand up pouches due to its versatility, durability, and cost-effectiveness. Polyethylene (PE), polypropylene (PP), and polyester (PET) are popular choices for plastic pouches. These materials provide excellent barrier properties against moisture, oxygen, and light, ensuring the freshness and integrity of packaged products. Plastic pouches are also lightweight, flexible, and resistant to punctures and tears, making them ideal for a wide range of applications, including food, beverages, household products, and more.

2. Paper:

Paper-based flat bottom stand up pouches are an eco-friendly alternative to traditional plastic pouches, offering biodegradability and recyclability. These pouches are typically made from kraft paper or paperboard materials, which are sourced from sustainable forests and have a lower environmental impact compared to plastics. Paper pouches can be laminated with a thin layer of plastic or aluminum foil to enhance barrier properties and protect contents from moisture and grease. They are commonly used for dry food products, snacks, grains, and powders.

3. Foil:

Foil or metalized films are often used in the construction of flat bottom stand up pouches to provide superior barrier properties and protection against light, moisture, and oxygen. Foil pouches offer excellent moisture resistance and oxygen barrier, making them ideal for preserving the freshness and flavor of sensitive products such as coffee, tea, spices, and snacks. Foil pouches also provide a high level of opacity, which helps protect light-sensitive ingredients from degradation. Additionally, foil pouches can be customized with metallic finishes or printed designs to enhance product visibility and brand aesthetics.

These are just a few examples of the materials used in the production of flat bottom stand up pouches. Manufacturers can also utilize combinations of different materials to achieve specific performance requirements and create customized packaging solutions tailored to their unique needs and preferences.

Applications of Flat Bottom Stand Up Pouches

Flat bottom stand up pouches are versatile packaging solutions that find applications across various industries due to their practical design, flexibility, and protective properties. Here are some common applications of flat bottom stand up pouches:

1. Food Industry:

Flat bottom stand up pouches are widely used in the food industry for packaging a diverse range of products, including:

- Snacks: Such as chips, nuts, dried fruits, and trail mixes.

- Bakery Items: Like cookies, biscuits, granola bars, and pastries.

- Coffee and Tea: Ground coffee, whole beans, loose leaf tea, and tea blends.

- Confectionery: Chocolates, candies, gummies, and other sweet treats.

- Frozen Foods: Pre-packaged meals, fruits, vegetables, and seafood.

These pouches offer excellent barrier properties to protect food products from moisture, oxygen, light, and other environmental factors, ensuring freshness and extending shelf life. They are also lightweight, portable, and resealable, making them convenient for consumers and suitable for on-the-go snacking.

2. Pharmaceutical Industry:

In the pharmaceutical industry, flat bottom stand up pouches are utilized for packaging various healthcare and medical products, including:

- Nutritional Supplements: Such as vitamins, minerals, and protein powders.

- Pharmaceuticals: Over-the-counter medications, capsules, tablets, and powders.

- Personal Care Products: Lotions, creams, ointments, and topical treatments.

These pouches provide a secure and hygienic packaging solution for pharmaceutical products, protecting them from contamination, tampering, and degradation. They can be customized with child-resistant closures, tamper-evident seals, and clear windows for product visibility and compliance with regulatory requirements.

3. Pet Food Industry:

In the pet food industry, flat bottom stand up pouches are used for packaging various pet food and treats, including:

- Dry Pet Food: Kibble, pellets, and crunchy treats for dogs, cats, and other pets.

- Pet Treats: Soft treats, jerky, dental chews, and training rewards.

- Pet Supplements: Vitamins, joint supplements, and digestive aids for pets.

These pouches offer durable and convenient packaging solutions for pet food products, keeping them fresh, flavorful, and free from moisture and pests. They are available in different sizes and formats to accommodate various pet food formulations and packaging requirements, making them popular among pet owners and pet food manufacturers alike.

Overall, flat bottom stand up pouches offer versatile packaging solutions for the food, pharmaceutical, and pet food industries, providing excellent protection, convenience, and shelf appeal for a wide range of products.

Design Features of Flat Bottom Stand Up Pouches

Flat bottom stand up pouches are designed with several key features that enhance their functionality, convenience, and visual appeal. Here are some common design features of flat bottom stand up pouches:

1. Flat Bottom Design:

The distinctive flat bottom design of these pouches provides stability and balance, allowing them to stand upright on store shelves, countertops, or display racks without the need for additional support. This unique feature maximizes product visibility and enhances shelf presence, making the pouches more attractive to consumers and facilitating easy merchandising.

2. Zipper Closure:

Many flat bottom stand up pouches are equipped with a resealable zipper closure mechanism, allowing consumers to open and close the pouches multiple times while keeping the contents fresh and secure. The zipper closure provides convenience and ease of use, enabling consumers to portion out the product as needed and reseal the pouch for future consumption, extending the shelf life of the contents.

3. Clear Windows:

Some flat bottom stand up pouches feature clear windows or panels that allow consumers to see the contents inside the pouch without opening it. Clear windows provide transparency and visibility, allowing consumers to inspect the product quality, quantity, and appearance before making a purchase decision. This feature is particularly beneficial for products with visually appealing or premium-quality contents, such as snacks, confectionery, or gourmet foods.

4. Custom Printing and Branding:

Flat bottom stand up pouches offer ample surface area for custom printing, branding, and product labeling. Manufacturers can customize the pouches with vibrant graphics, logos, product information, and marketing messages to create eye-catching packaging designs that resonate with consumers and reinforce brand identity. Custom printing allows brands to differentiate themselves in the competitive marketplace and effectively communicate product features and benefits to target audiences.

5. Tear Notches and Hang Holes:

Many flat bottom stand up pouches are equipped with tear notches or perforations that facilitate easy opening and access to the contents inside the pouch. Tear notches allow consumers to tear open the pouches without the need for scissors or other tools, providing convenience and user-friendly packaging. Additionally, some pouches feature hang holes or Euro slots that enable retailers to display the pouches on peg hooks or hang strips for efficient merchandising and space optimization.

Environmental Impact of Flat Bottom Stand Up Pouches

Flat bottom stand up pouches offer several environmental advantages compared to traditional packaging options, but their impact depends on factors such as material composition, recycling infrastructure, and sustainable practices. Here’s an overview of the environmental impact of flat bottom stand up pouches:

1. Recyclability:

The recyclability of flat bottom stand up pouches depends on the materials used in their construction. While some pouches are made from recyclable materials such as polyethylene (PE), polypropylene (PP), or paper, others may incorporate multiple layers of different materials, making recycling more challenging. Additionally, pouches with metalized or foil layers may not be accepted by all recycling facilities.

To improve recyclability, manufacturers are increasingly using mono-material or recyclable barrier films in flat bottom stand up pouches. These materials are designed to be compatible with existing recycling streams, enabling pouches to be recycled along with other plastic or paper products. However, consumers must ensure proper separation and disposal of pouches to maximize recycling rates and minimize contamination.

2. Sustainability Initiatives:

Many companies are implementing sustainability initiatives to minimize the environmental impact of flat bottom stand up pouches throughout their lifecycle. These initiatives may include:

Material Reduction: Reducing the amount of packaging material used in pouch construction to minimize resource consumption and waste generation.

Bio-Based Materials: Incorporating bio-based or renewable materials into pouch construction to reduce reliance on fossil fuels and lower carbon emissions.

Recycling Programs: Partnering with recycling facilities and organizations to promote pouch recycling and increase recycling rates among consumers.

Circular Economy: Adopting circular economy principles by designing pouches for recyclability, reuse, or compostability, and participating in closed-loop recycling systems.

By implementing these sustainability initiatives, manufacturers can minimize the environmental impact of flat bottom stand up pouches and contribute to a more sustainable packaging industry. Additionally, consumer education and engagement play a crucial role in encouraging responsible disposal practices and supporting recycling efforts.

Cost Considerations of Flat Bottom Stand Up Pouches

When evaluating the cost of flat bottom stand up pouches, it’s essential to consider both the initial investment and the long-term savings associated with these packaging solutions. Here’s an overview of the cost considerations:

1. Initial Investment:

The initial investment in flat bottom stand up pouches includes expenses related to design, material procurement, printing, and production. Factors that influence the initial cost of pouches include:

Material Type: The cost of materials used in pouch construction can vary depending on factors such as material composition, thickness, and barrier properties. High-quality barrier films or specialty materials may incur higher costs compared to standard options.

Printing and Design: Custom printing and branding features add to the initial cost of pouches. Complex graphics, multiple colors, or special finishes may increase printing costs.

Production Volume: Economies of scale apply to pouch production, with larger production volumes typically resulting in lower unit costs. However, smaller production runs may incur higher setup costs per unit.

Additional Features: Features such as zipper closures, tear notches, clear windows, and hang holes may add to the initial cost of pouches.

2. Long-Term Savings:

While flat bottom stand up pouches may have higher initial costs compared to some traditional packaging options, they offer potential long-term savings and cost efficiencies, including:

Reduced Material Usage: Flat bottom stand up pouches often require less material compared to rigid packaging formats such as cans or jars, resulting in material savings and reduced shipping costs due to lighter weight.

Space Efficiency: The compact and stackable nature of pouches reduces storage space requirements during transportation and warehousing, potentially lowering storage costs.

Extended Shelf Life: High-quality barrier films used in pouch construction help extend the shelf life of packaged products, reducing food waste and potential losses due to spoilage or damage.

Brand Differentiation: Innovative packaging designs and custom printing options can enhance brand visibility, customer engagement, and product appeal, potentially leading to increased sales and revenue.

Customization Options for Flat Bottom Stand Up Pouches

Flat bottom stand up pouches offer a wide range of customization options to meet the unique branding and packaging requirements of different products and industries. Here are some common customization options available for flat bottom stand up pouches:

1. Printing Capabilities:

Flat bottom stand up pouches can be fully customized with high-quality printing to showcase brand logos, product images, promotional messages, and nutritional information. Printing capabilities include:

Flexographic Printing: Ideal for simple designs and large print runs, flexographic printing offers cost-effective solutions for basic branding and product labeling.

Rotogravure Printing: Suitable for intricate designs, fine details, and vibrant colors, rotogravure printing delivers premium-quality graphics and enhanced shelf appeal.

Digital Printing: With variable data printing capabilities, digital printing enables on-demand customization, short print runs, and personalization for targeted marketing campaigns.

2. Size Variations:

Flat bottom stand up pouches are available in a wide range of sizes and dimensions to accommodate different product volumes and packaging requirements. Size variations include:

Small Sizes: Ideal for single-serve portions, sample packs, and trial sizes, small pouches offer convenience and portability for on-the-go consumption.

Medium Sizes: Suitable for standard packaging needs, medium-sized pouches are versatile and widely used for a variety of products across industries.

Large Sizes: Designed for bulk packaging and family-sized portions, large pouches provide ample storage capacity and value for consumers.

3. Additional Features:

In addition to printing capabilities and size variations, flat bottom stand up pouches can be customized with various additional features to enhance functionality and consumer convenience. These features include:

Zipper Closures: Resealable zipper closures provide easy opening and reclosing for multiple uses, ensuring product freshness and extending shelf life.

Tear Notches: Perforated tear notches allow for easy opening without the need for scissors or other tools, enhancing user experience and convenience.

Clear Windows: Transparent windows or panels offer product visibility and showcase the contents inside the pouch, allowing consumers to inspect the product before purchase.

Factors to Consider When Choosing Flat Bottom Stand Up Pouches

When selecting flat bottom stand up pouches for packaging needs, it’s essential to consider several factors to ensure the pouches meet the specific requirements and goals of the product and brand. Here are key factors to consider:

1. Product Type:

Different products have unique characteristics and packaging requirements that influence the choice of flat bottom stand up pouches. Considerations include:

Product Composition: Determine if the product is dry, liquid, or semi-liquid, as well as its texture, viscosity, and shelf stability.

Product Size and Shape: Choose pouch sizes and dimensions that accommodate the product volume and shape without excess space or overfilling.

Product Sensitivity: Assess the product’s sensitivity to light, moisture, oxygen, and external contaminants, and select pouch materials with suitable barrier properties.

2. Packaging Requirements:

Understanding the specific packaging requirements is crucial for selecting flat bottom stand up pouches that meet functional and logistical needs. Factors to consider include:

Barrier Properties: Evaluate the desired level of protection against moisture, oxygen, light, and other environmental factors, and choose pouch materials with appropriate barrier properties.

Resealability: Determine if resealable features such as zipper closures or tear notches are necessary for multiple uses and product freshness.

Storage and Transportation: Consider space efficiency, stackability, and durability for storage, transportation, and display purposes.

3. Branding Goals:

Flat bottom stand up pouches offer ample opportunities for branding and customization to align with brand identity and marketing objectives. Considerations include:

Printing and Design: Assess printing capabilities, including color options, graphics quality, and customization features such as matte or glossy finishes.

Visual Appeal: Choose pouch designs and features that enhance shelf presence, attract consumer attention, and differentiate the product from competitors.

Consumer Engagement: Identify opportunities for interactive packaging elements such as clear windows, QR codes, or augmented reality experiences to engage consumers and communicate brand stories.

Tips for Using Flat Bottom Stand Up Pouches Effectively

To maximize the effectiveness of flat bottom stand up pouches for packaging, it’s essential to follow proper filling techniques and storage recommendations. Here are some tips to ensure optimal performance and product integrity:

1. Proper Filling Techniques:

Uniform Filling: Ensure consistent and uniform filling of pouches to avoid overfilling or underfilling, which can affect product presentation and seal integrity.

Avoid Air Entrapment: Minimize air pockets or bubbles within the pouch during filling to prevent bulging, distortion, or compromised seal integrity.

Seal Area Clearance: Maintain clear margins along the seal area to prevent product contamination and ensure proper sealing during the heat sealing process.

Seal Quality Inspection: Regularly inspect seal quality to detect any defects or inconsistencies that may compromise product freshness and shelf life.

2. Storage Recommendations:

Temperature Control: Store filled pouches in a controlled environment with stable temperatures to prevent exposure to heat, cold, or fluctuations that may affect product quality.

Avoid Direct Sunlight: Keep pouches away from direct sunlight or UV radiation, which can degrade product ingredients and packaging materials over time.

Dry Environment: Store pouches in a dry environment to prevent moisture absorption, condensation, or mold growth, particularly for moisture-sensitive products.

Stacking and Handling: Avoid stacking heavy objects on top of pouches during storage or transportation to prevent crushing, deformation, or damage to the packaging and contents.

By following these tips for proper filling techniques and storage recommendations, businesses can ensure the effective use of flat bottom stand up pouches for packaging various products while maintaining product quality and integrity throughout the supply chain.

Common Misconceptions About Flat Bottom Stand Up Pouches

Despite their numerous advantages, flat bottom stand up pouches are sometimes subject to misconceptions that may overlook their versatility and durability. Here are two common misconceptions and the realities behind them:

1. Limited Applications:

Misconception: Some believe that flat bottom stand up pouches are suitable only for specific types of products or industries, such as snacks or pet food.

Reality: Flat bottom stand up pouches are highly versatile and can accommodate a wide range of products across various industries, including food, pharmaceuticals, cosmetics, and household goods. Their customizable design, barrier properties, and printing capabilities make them suitable for packaging dry goods, liquids, powders, and more. With proper customization and material selection, flat bottom stand up pouches can meet the packaging needs of diverse product categories, from food and beverage to personal care and industrial applications.

2. Lack of Durability:

Misconception: Some believe that flat bottom stand up pouches lack durability compared to rigid packaging formats such as bottles or cans, leading to concerns about product protection and shelf stability.

Reality: Flat bottom stand up pouches are constructed from durable materials such as laminated films, which provide excellent protection against punctures, tears, and environmental factors. Additionally, their flat bottom design enhances stability and prevents tipping or spilling, even when filled with liquids or heavy contents. With proper sealing and storage, flat bottom stand up pouches can maintain product freshness and integrity throughout the supply chain, ensuring a longer shelf life and minimizing product waste.

By dispelling these common misconceptions, businesses can recognize the full potential of flat bottom stand up pouches as versatile, durable, and effective packaging solutions for a wide range of products and applications.

Comparison with Other Packaging Options: Flat Bottom Stand Up Pouches vs. Flexible and Rigid Packaging

When evaluating packaging options for products, businesses often consider the advantages and limitations of various packaging formats, including flat bottom stand up pouches, flexible packaging, and rigid packaging. Here’s a comparison of these options:

1. Flat Bottom Stand Up Pouches:

Advantages:

- Versatility: Suitable for a wide range of products, including dry goods, liquids, and powders.

- Space Efficiency: Compact design reduces storage space and shipping costs compared to rigid packaging formats.

- Customization: Offers extensive printing capabilities and customizable features for branding and product differentiation.

- Barrier Properties: Provides excellent protection against moisture, oxygen, and light to maintain product freshness and integrity.

- Sustainability: Lightweight design and materials contribute to reduced carbon footprint and environmental impact compared to some rigid packaging options.

Disadvantages:

- Limited Rigidity: While more rigid than traditional flexible packaging, flat bottom stand up pouches may not offer the same level of structural integrity as rigid containers for certain products.

2. Flexible Packaging:

Advantages:

- Lightweight: Lightweight materials and flexible design reduce packaging weight and shipping costs.

- Space Savings: Flexible packaging can be compressed or flattened, saving storage space during transportation and warehousing.

- Versatility: Suitable for a wide range of products, including snacks, beverages, and personal care items.

- Customization: Offers printing capabilities for branding and product information, although less extensive than flat bottom stand up pouches.

Disadvantages:

- Limited Rigidity: May lack sufficient structural support for heavier or bulkier products compared to rigid packaging formats.

- Perceived Quality: Some consumers perceive flexible packaging as less premium or durable compared to rigid containers.

3. Rigid Packaging:

Advantages:

- Durability: Offers superior structural integrity and protection for fragile or heavy products.

- Premium Perception: Rigid containers convey a sense of quality and luxury, enhancing brand perception and consumer appeal.

- Shelf Presence: Sturdy construction and clear visibility showcase products effectively on retail shelves.

Disadvantages:

- Weight and Size: Rigid packaging is heavier and bulkier than flexible options, increasing shipping costs and storage space requirements.

- Environmental Impact: Some rigid materials, such as glass or certain plastics, have a higher environmental footprint compared to flexible or sustainable packaging alternatives.

- Limited Versatility: Rigid containers may be less versatile and adaptable to different product types compared to flexible or customizable pouch formats.

Future Trends in Flat Bottom Stand Up Pouches

As the packaging industry continues to evolve, flat bottom stand up pouches are poised to embrace future trends driven by technological advancements and sustainable innovations. Here are some anticipated trends shaping the future of flat bottom stand up pouches:

1. Technological Advancements:

Smart Packaging Solutions: Integration of smart technologies such as QR codes, NFC tags, or RFID sensors into flat bottom stand up pouches to enable product tracking, authentication, and interactive consumer experiences.

Augmented Reality Packaging: Utilization of augmented reality (AR) technology to enhance consumer engagement by providing immersive digital content or virtual product demonstrations directly on pouch packaging.

Anti-Counterfeiting Measures: Implementation of advanced authentication features such as tamper-evident seals, holographic labels, or invisible ink markings to combat counterfeit products and ensure product integrity.

2. Sustainable Innovations:

Biodegradable Materials: Adoption of biodegradable or compostable materials for flat bottom stand up pouches to reduce environmental impact and address concerns about plastic pollution and waste.

Recyclable Barrier Films: Development of recyclable barrier films with enhanced barrier properties to improve the recyclability of pouches while maintaining product freshness and shelf life.

Circular Economy Initiatives: Collaboration across the packaging value chain to implement circular economy principles, including closed-loop recycling systems and sustainable sourcing of materials, to minimize waste and promote resource efficiency.

Life Cycle Assessments: Integration of life cycle assessments (LCAs) into packaging design processes to evaluate the environmental impact of flat bottom stand up pouches across their entire life cycle, from raw material extraction to end-of-life disposal.

Conclusion

In conclusion, flat bottom stand up pouches offer a versatile, efficient, and sustainable packaging solution for a wide range of products across industries. With their customizable design, excellent barrier properties, and space-saving features, these pouches meet the evolving needs of businesses and consumers alike. By considering factors such as product type, packaging requirements, and branding goals, businesses can make informed decisions when choosing flat bottom stand up pouches for their packaging needs.

Additionally, as the packaging industry continues to evolve, technological advancements and sustainable innovations are shaping the future of flat bottom stand up pouches, paving the way for smart packaging solutions, biodegradable materials, and circular economy initiatives. By embracing these trends, manufacturers and brands can drive positive change in the packaging industry while delivering innovative and environmentally friendly packaging solutions. Overall, flat bottom stand up pouches represent a forward-thinking approach to packaging that prioritizes functionality, sustainability, and consumer satisfaction.