Home » Bags & Pouches » Flat Bottom Pouches » Block Bottom Bag

Block Bottom Bag

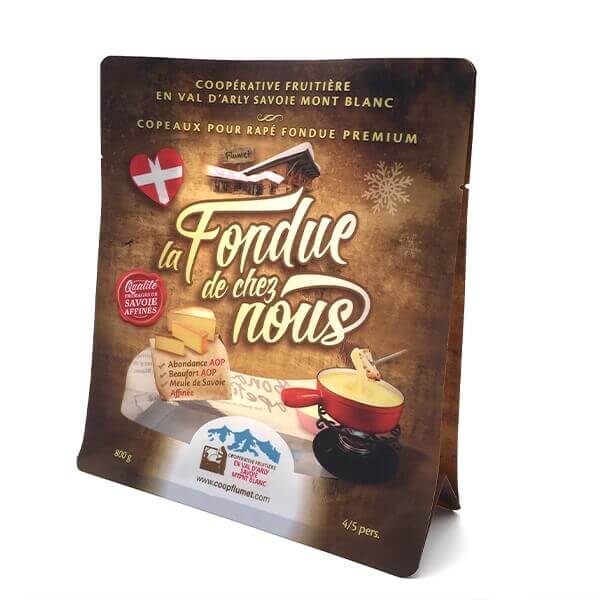

Block bottom bags are pouches with the completely flat bottom, also called box pouches or quad seal pouches allow specialty food creators to proudly display their brands on store shelves.

Please note that we have a MOQ for our pouch. For pouches in stock, the MOQ is 500 pcs. For customized pouches, please see the MOQ as followed:

1, Digital Printing — 500 pcs

2, Gravure Printing — 5,000pcs

Rinpac assists you throughout your project: bag shape, material, thickness, capacity and printing options. Please contact us or mark your requirements on the inquiry quotation.

Order single or thousands of items at a time. Our warehouse and flexible shipping options are available for last-minute, deadline critical orders.

- Free Sample

*Customization is always available, please mark down your need in cart or just contact us.

Specification of Block Bottom Bag

| Materials | Per customer’s packaging needs. Using materials such as clear poly, metalized films, foil laminations and kraft paper. All pouches are made of food grade solvent free packaging materials. |

| Sizes | Per customers’ needs. |

| Styles | Quad sealed flat bottom |

| Resealable Features | Press-to-close zippers: Economical and commonly used |

| Tin Ties: Available in Plastic and Kraft | |

| Additional Features | Tear notches |

| Degassing Valves | |

| Knocked out windows providing a sneak peek of what’s inside: clear window, frosted window, or matte finish with glossy clear window | |

| Laser scoring or laser perforation | |

| Printing | Glossy printing |

| Matte finish printing | |

| Glossy printing with spot matte finishes | |

| Per customer’s design and requirements. | |

| Accessories | Zipper for reclosure |

| Tin Tie for reclosure | |

| Degassing Valve |

Request A Quote - Block Bottom Bag

Need something helped in a short time? We’ve got a plan for you.

Introduction to Block Bottom Bags

Block Bottom Bags, also known as flat bottom bags or box pouches, are innovative packaging solutions designed to provide stability, convenience, and optimal shelf presentation for a wide range of products. Unlike traditional flat pouches, block bottom bags feature a unique construction that includes gussets on both sides and a flat bottom panel, allowing them to stand upright on store shelves and countertops.

These bags are constructed using high-quality flexible materials such as plastic films, paper, or laminates, which provide excellent barrier properties to protect the contents from moisture, oxygen, light, and other external factors. Block bottom bags are widely used in various industries, including food and beverage, pet care, pharmaceuticals, and household products, due to their versatility and practicality.

With their distinctive block bottom design, these bags offer several advantages over traditional packaging options, including improved stability, increased branding opportunities, and enhanced consumer convenience. As such, block bottom bags have become a popular choice for businesses looking to differentiate their products, attract consumer attention, and optimize their packaging performance.

In this comprehensive guide, we will explore the features, benefits, applications, and customization options of block bottom bags, as well as provide valuable tips for effective utilization and storage. Whether you’re packaging snacks, coffee, pet food, or household items, block bottom bags offer a versatile and efficient packaging solution that meets the demands of modern consumers and businesses alike.

Rinpac offers top quality flat bottom pouch coffee. Get a free quote now. Thanks

Advantages of Block Bottom Bags

Block bottom bags offer a multitude of advantages that make them an ideal packaging choice for various products across different industries. Here are some key benefits of using block bottom bags:

1. Durability

Block bottom bags are constructed using high-quality materials and feature a sturdy design that ensures durability and resilience. The reinforced gussets and flat bottom panel provide structural integrity, preventing the bag from collapsing or deforming during storage, transportation, or handling. This durability protects the contents from damage, ensuring that products reach consumers in optimal condition.

2. Shelf Appeal

The unique block bottom design of these bags allows them to stand upright on store shelves, creating an attractive and eye-catching display for products. The flat bottom panel provides stability and support, preventing the bag from tipping over and enhancing its visual presence. Additionally, block bottom bags offer ample surface area for branding, product information, and eye-catching graphics, further increasing shelf appeal and attracting consumer attention.

3. Versatility

Block bottom bags are incredibly versatile and suitable for packaging a wide range of products, including dry goods, snacks, coffee, pet food, and more. Their flexible design accommodates various shapes and sizes, making them adaptable to different packaging needs. Whether you’re packaging granola, tea leaves, or household items, block bottom bags offer a versatile and practical solution that meets the diverse requirements of modern consumers and businesses.

Overall, the durability, shelf appeal, and versatility of block bottom bags make them a preferred packaging choice for businesses looking to enhance product presentation, protect contents, and attract consumer interest. With their combination of functionality and aesthetics, block bottom bags offer a winning solution for packaging needs across numerous industries.

Applications of Block Bottom Bags

Block bottom bags are incredibly versatile packaging solutions suitable for a wide range of products across various industries. Their robust construction, attractive presentation, and functional design make them ideal for packaging diverse items. Here are some common applications of block bottom bags:

1. Food Packaging

Block bottom bags are extensively used in the food industry for packaging a variety of products, including:

- Snacks: Chips, nuts, popcorn, and pretzels.

- Bakery Items: Cookies, biscuits, pastries, and granola bars.

- Coffee and Tea: Ground coffee, whole beans, loose leaf tea, and tea blends.

- Confectionery: Chocolates, candies, and gummies.

- Dried Fruits and Nuts: Raisins, almonds, cashews, and dried apricots.

- Grains and Cereals: Rice, pasta, quinoa, and oatmeal.

The durable and moisture-resistant properties of block bottom bags help preserve the freshness and flavor of food products, ensuring they remain intact and protected from external elements.

2. Pet Food Packaging

Block bottom bags are popular choices for packaging pet food products, including:

- Dry Pet Food: Kibble and pellets for dogs, cats, and other pets.

- Treats: Biscuits, jerky, and dental chews.

- Bird Seed: Seeds and grains for birds.

The sturdy construction of block bottom bags ensures that pet food products are securely sealed and protected from moisture, pests, and contamination, maintaining their quality and nutritional value.

3. Industrial Products Packaging

Block bottom bags are also used for packaging various industrial products, including:

- Chemicals: Powders, granules, and pellets.

- Aggregates: Sand, gravel, and stones.

- Building Materials: Cement, mortar, and grout.

- Seeds and Fertilizers: Agricultural seeds, fertilizers, and soil amendments.

These bags provide durable and reliable packaging solutions for industrial products, offering protection against moisture, dust, and other environmental factors during storage and transportation.

In summary, block bottom bags are versatile packaging options suitable for a wide range of products, including food items, pet supplies, and industrial goods. Their durability, versatility, and attractive presentation make them an ideal choice for businesses looking to package and showcase their products effectively.

Get top quality flat bottom pouches. Get a free quote now. Thanks

Materials Used in Block Bottom Bags

Block bottom bags are manufactured using a variety of materials, each offering unique properties and benefits to suit different packaging requirements. Here are the common materials used in the production of block bottom bags:

1. Paper

Paper block bottom bags are made from renewable and biodegradable materials, making them an environmentally friendly option for packaging. These bags are commonly used for packaging food products, such as snacks, coffee, and bakery items. Paper block bottom bags offer good printability, allowing for vibrant graphics and branding to be displayed on the packaging surface.

2. Plastic

Plastic block bottom bags are typically made from polyethylene (PE) or polypropylene (PP) materials, which provide excellent barrier properties against moisture, oxygen, and light. These bags are commonly used for packaging snacks, pet food, and industrial products. Plastic block bottom bags offer durability and flexibility, ensuring that packaged products remain protected and secure during storage and transportation.

3. Biodegradable Options

With increasing concerns about environmental sustainability, biodegradable materials are becoming more popular for manufacturing block bottom bags. Biodegradable options may include materials such as compostable films made from plant-based sources like corn starch or sugarcane. These bags offer similar barrier properties to traditional plastic bags while being compostable in industrial composting facilities, reducing environmental impact.

By offering a range of material options, block bottom bags cater to diverse packaging needs while also considering environmental sustainability. Whether businesses prioritize recyclability, durability, or biodegradability, there is a suitable material choice available for their packaging requirements.

Manufacturing Process of Block Bottom Bags

The production of block bottom bags involves several key steps, including printing, laminating, and bag making, to create high-quality packaging solutions. Here’s an overview of the manufacturing process:

1. Printing

The manufacturing process begins with printing the design and branding elements onto the chosen material, whether it’s paper or plastic. Printing is typically done using advanced printing technologies such as flexography or gravure printing, which allow for precise and vibrant graphics to be applied to the surface of the material. This step is crucial for creating eye-catching packaging that effectively communicates product information and branding.

2. Laminating

After printing, the printed material may undergo a laminating process to enhance its durability and barrier properties. Laminating involves applying a layer of protective film or coating onto the printed surface, which helps to seal the ink, prevent smudging, and provide additional protection against moisture, oxygen, and UV radiation. Laminating also improves the overall strength and tear resistance of the material, ensuring that the finished bags can withstand handling and transportation.

3. Bag Making

Once the printed and laminated material is ready, it is fed into bag making machines to produce the final block bottom bags. The bag making process involves folding, sealing, and shaping the material into the desired bag format. For block bottom bags, the material is folded and sealed along the edges to create side gussets, and then the bottom is sealed to form a flat bottom panel. This unique construction allows the bag to stand upright on its own, providing stability and enhancing product presentation on store shelves.

Throughout the manufacturing process, stringent quality control measures are implemented to ensure that the finished block bottom bags meet the highest standards of quality, consistency, and performance. This includes thorough inspections of the printed material, laminated film, and finished bags to identify any defects or imperfections and address them promptly.

By employing advanced printing, laminating, and bag making technologies, manufacturers can produce block bottom bags that not only meet the functional and aesthetic requirements of packaging but also contribute to the overall success of products in the market.

Customization Options for Block Bottom Bags

Block bottom bags offer a wide range of customization options, allowing businesses to create packaging solutions that align with their brand identity and product specifications. From design to size and additional features, here are the key customization options available for block bottom bags:

1. Design

Customizing the design of block bottom bags enables businesses to showcase their brand identity and product messaging effectively. Design options may include:

- Branding Elements: Incorporating logos, brand colors, and taglines to reinforce brand recognition.

- Graphics and Images: Adding visually appealing graphics, illustrations, or product images to enhance shelf appeal.

- Product Information: Displaying essential product information, such as ingredients, nutritional facts, and usage instructions, to inform consumers.

2. Size

Block bottom bags can be customized in various sizes to accommodate different product quantities and dimensions. Businesses can choose from standard sizes or opt for bespoke sizing options to meet specific packaging requirements. Customizable size options allow for flexibility in packaging different volumes of products while maximizing shelf space and minimizing material waste.

3. Additional Features

In addition to design and size customization, block bottom bags can be enhanced with various additional features to improve functionality and user experience. Some common additional features include:

- Zipper Closures: Adding resealable zipper closures for easy opening and closing, ensuring product freshness and convenience for consumers.

- Window Panels: Incorporating transparent window panels to provide visibility of the packaged product, allowing consumers to see the contents inside.

- Tear Notches: Introducing tear notches for easy opening without the need for scissors or other tools, enhancing user convenience and accessibility.

- Valve Systems: Integrating one-way degassing valves for packaging coffee and other products that release gases, allowing for extended shelf life while maintaining product freshness.

By offering a wide range of customization options, block bottom bags empower businesses to create packaging solutions that effectively communicate their brand identity, showcase their products, and meet the unique needs of consumers.

Environmental Impact of Block Bottom Bags

As businesses increasingly prioritize sustainability, the environmental impact of packaging materials has become a crucial consideration. Block bottom bags offer several environmentally friendly features that contribute to reducing waste and minimizing environmental footprint. Here’s a look at two key aspects of their environmental impact:

1. Recycling

Many block bottom bags are made from recyclable materials, such as paper and certain types of plastics. These materials can be collected, sorted, and processed through recycling facilities to be reused in the manufacturing of new products. By choosing recyclable block bottom bags, businesses can support circular economy principles and reduce the demand for virgin materials, ultimately conserving natural resources and energy.

2. Biodegradability

In addition to recyclability, some block bottom bags are designed to be biodegradable or compostable. These bags are made from materials that break down naturally over time, either in industrial composting facilities or in home composting systems. Biodegradable block bottom bags offer a sustainable end-of-life solution, reducing the accumulation of waste in landfills and minimizing environmental pollution.

By opting for recyclable or biodegradable block bottom bags, businesses can demonstrate their commitment to environmental stewardship and meet the growing consumer demand for sustainable packaging solutions. Furthermore, investing in eco-friendly packaging can enhance brand reputation and appeal to environmentally conscious consumers, driving positive brand perception and loyalty.

Cost Considerations for Block Bottom Bags

When choosing packaging solutions, cost is a crucial factor that businesses must consider alongside other considerations such as functionality, durability, and environmental impact. Block bottom bags offer several cost considerations that can impact overall packaging expenses. Here’s a breakdown of key cost considerations associated with block bottom bags:

1. Material Cost

The choice of material significantly impacts the cost of block bottom bags. Paper-based materials tend to be more affordable compared to certain types of plastics or biodegradable options. However, the cost may vary depending on factors such as material thickness, quality, and availability. Understanding the cost implications of different materials is essential for selecting an option that aligns with budgetary constraints without compromising on quality.

2. Production Volume

The volume of block bottom bags required for packaging affects overall production costs. Larger production volumes typically result in lower unit costs due to economies of scale. Businesses ordering larger quantities of block bottom bags may benefit from bulk pricing discounts offered by manufacturers or suppliers. However, it’s essential to assess demand forecasts and storage capabilities to avoid overstocking and unnecessary expenses.

3. Customization

Customizing block bottom bags with unique designs, sizes, and additional features may incur additional costs compared to standard options. The complexity of customization requirements, such as intricate graphics or specialized features like zipper closures or window panels, can influence production costs. Balancing customization needs with budgetary considerations is essential for optimizing packaging investments.

4. Transportation and Logistics

Shipping and logistics costs should also be factored into the overall cost of block bottom bags. Bulkier or heavier packaging materials may incur higher transportation expenses, particularly for long-distance shipments. Businesses should consider sourcing options that minimize transportation costs while ensuring timely delivery and product availability.

5. Environmental Impact

While sustainability initiatives may entail initial investments in eco-friendly packaging options, such as recyclable or biodegradable block bottom bags, businesses should evaluate the long-term cost benefits. Sustainable packaging solutions can lead to potential cost savings through reduced waste disposal fees, improved brand reputation, and increased customer loyalty.

By carefully assessing these cost considerations, businesses can make informed decisions when selecting block bottom bags that align with their budgetary requirements while meeting quality, functionality, and sustainability objectives.

Future Trends in Block Bottom Bags

As the packaging industry continues to evolve, several emerging trends are shaping the future of block bottom bags. These trends reflect changing consumer preferences, technological advancements, and sustainability initiatives. Here are some key trends to watch out for:

1. Sustainable Materials

The demand for eco-friendly packaging solutions is driving innovation in sustainable materials for block bottom bags. Manufacturers are exploring alternative materials such as bio-based plastics, compostable films, and recycled content to reduce environmental impact and meet consumer expectations for sustainable packaging.

2. Smart Packaging Solutions

Advancements in technology are enabling the development of smart packaging solutions for block bottom bags. Incorporating features such as QR codes, RFID tags, and NFC chips allows brands to provide interactive and engaging experiences for consumers, such as accessing product information, tracking authenticity, and participating in loyalty programs.

3. Customization and Personalization

Consumers are increasingly seeking personalized experiences, and packaging is no exception. Brands are leveraging digital printing technologies and variable data printing to create customized block bottom bags with unique designs, messaging, and promotions tailored to individual preferences and occasions.

4. Enhanced Functionality

Block bottom bags are evolving to offer enhanced functionality beyond basic packaging requirements. Features such as resealable closures, easy-open tear notches, and built-in dispensing mechanisms improve convenience and usability for consumers while maintaining product freshness and integrity.

5. Interactive Packaging Design

Interactive packaging design elements, such as augmented reality (AR) experiences, gamification, and sensory engagement, are becoming more prevalent in block bottom bags. These interactive features create memorable brand experiences and foster deeper connections with consumers, driving brand loyalty and repeat purchases.

6. Regulatory Compliance and Safety

Stringent regulations and consumer safety concerns are driving manufacturers to prioritize compliance and safety in block bottom bag production. This includes adherence to food safety standards, compliance with packaging material regulations, and implementation of quality control measures to ensure product integrity and consumer trust.

By staying abreast of these future trends, businesses can adapt their packaging strategies to meet evolving consumer needs, capitalize on emerging opportunities, and maintain a competitive edge in the market.

Conclusion

In conclusion, block bottom bags offer a versatile and sustainable packaging solution for various industries, including food, pet products, and industrial goods. With their enhanced stability, shelf appeal, and customization options, block bottom bags cater to the evolving needs of businesses and consumers alike.

As the packaging landscape continues to evolve, embracing future trends such as sustainable materials, smart packaging solutions, and enhanced functionality will be essential for staying competitive and meeting consumer expectations. By prioritizing sustainability, innovation, and regulatory compliance, businesses can position themselves for success in the dynamic packaging market.

Overall, block bottom bags represent not only a practical packaging solution but also a strategic investment in brand image, consumer engagement, and environmental responsibility. With careful consideration of cost, customization, and future trends, businesses can harness the full potential of block bottom bags to drive growth, profitability, and sustainability.

Rinpac offers high quality bags and pouches for your business. Contact us. Thanks

FAQs

What is a block bottom bag?

A block bottom bag, also known as a brick bottom bag, is a type of packaging with a rectangular bottom that provides stability and allows it to stand upright on shelves. It is commonly used for packaging various products such as snacks, pet food, and agricultural products.

What do you call a bag with a flat bottom?

A bag with a flat bottom is often referred to simply as a flat bottom bag. This type of bag is characterized by its flat base, which enables it to stand upright on its own, providing stability and making it easier to display and store.

Is a quad seal bag better than a flat bottom bag?

The choice between a quad seal bag and a flat bottom bag depends on specific packaging requirements and preferences. Quad seal bags offer more structural integrity and can hold heavier contents, while flat bottom bags provide a stable base for standing and efficient use of shelf space. Each has its advantages depending on the intended use.

What is a star seal bottom bag?

A star seal bottom bag is a type of plastic bag with a sealed bottom that forms a star-like pattern when viewed from the outside. This design enhances the bag’s strength and prevents leaks by evenly distributing the weight of the contents across multiple points.

What is a pinch bottom bag?

A pinch bottom bag, also known as a flat bottom bag or a brick bottom bag, is a type of packaging made from a single piece of material that is folded and sealed at the bottom using a pinching method. These bags are commonly used for packaging items like flour, sugar, and grains.

What is the difference between flat bottom pouch and stand up pouch?

While both flat bottom pouches and stand-up pouches are flexible packaging options, they differ primarily in their bottom design. Flat bottom pouches have a rectangular base that provides stability and allows them to stand upright on their own. Stand-up pouches, on the other hand, rely on their shape and internal structure to stand vertically without the need for a flat bottom.

What are barrier bags used for?

Barrier bags, also known as foil bags or metallized bags, are designed to protect products from external elements such as moisture, oxygen, light, and odor. They are commonly used for packaging sensitive items like food, pharmaceuticals, and electronics to maintain freshness and extend shelf life.

How do you stabilize the bottom of a bag?

The bottom of a bag can be stabilized by using various methods such as adding a cardboard or plastic insert, heat sealing the bottom for reinforcement, or incorporating a block bottom design that provides inherent stability. These techniques help prevent the bag from collapsing or tipping over when filled with contents.

What is a butcher bag?

A butcher bag, also known as a meat or poultry bag, is a type of packaging commonly used by butchers and meat processors to package fresh meat products for retail sale. These bags are typically made of durable materials like polyethylene and are designed to withstand the moisture and juices released by the meat.

What is a quad bag?

A quad bag refers to a type of packaging that utilizes a quad seal construction, which involves four separate seals at the corners of the bag. This design provides added strength and stability, making quad bags suitable for packaging heavy or bulky items while maintaining structural integrity. They are commonly used for products like pet food, snacks, and agricultural products.