Packaging Bags & Pouches Manufacturing

Rinpac is a renowned company in the Chinese marketplace. It has an incredible description of the accomplishments of manufacturing bags and pouches. The eye-catching products bring their customers back to them. The endeavor to bring promising outcomes for customers makes Rinpac distinctive among others. The method of manufacturing the bags and pouches proliferates the chances of selling like hotcakes. Rinpac also facilitates its wholesalers and marketers with free model bags. The quick shipping and 24/7 hours availability of our consultants is available for you. On the other hand, bags are capable to maintain their demand in the marketplace just because of the manufacturing process. The processing of bags is performed step by step under the instructions of experts.

Need short and quick plan for your project?

How to make packaging bags step by step

#1) Raw Materials For Making Packaging Bags & Pouches

The base of everything depends on its raw material. It is just like food that nourishes the entire model built on it. The raw material mostly used for packaging bags and pouches consist of different material which is processed as follows.

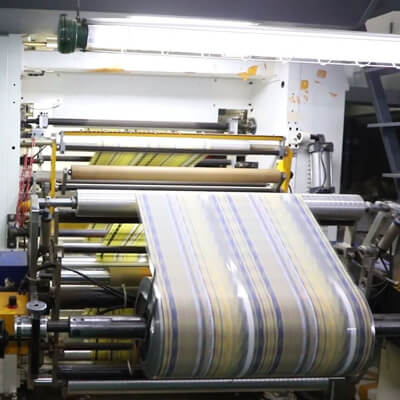

- The foremost priority of our manufacturers is to produce rare plastic bags by laminating them with different films. The film used is of excellent characteristics. Lamination is accomplished with three or four coatings of film, ordered from specialized blown film manufacturers. The lamination is performed under the customized requirements of buyers depending on the size and material of the bag to determine the type of film. The quality of the film is verified first. Trustworthy blown film manufacturers are prioritized. The lamination is suited for our bags like zipper bags, mylar bags, and other food packaging bags.

#02) Copperplate for making packaging bags and Pouches

As we have long-term experience in copperplate engraving, our manufacturing wins the trust of Buyers.

After lamination, the general composite bags are engraved by copper plate printing processes. Then processed with the perfect size and pattern of the plate according to the customer’s needs. As once copper plate engraving is completed, its size of it can no longer be modified. So, we provide the exact size plate of copper according to the customized bag. The engraving procedure satisfies buyers. That’s why our eye-pleasing bags and pouches are preferred. We use different methods for engraving like the gravure process.

- We confirm that the pattern and size are correct so that re-plating may be avoided. It declines our loss ratio and ensures on-time delivery. We ensure an uninterrupted supply of products.

#03) Printing during the Packaging of Bags and Pouches Production Process

Rinpac owns an outstanding team and worthy workers. We accommodate modern machinery and competent employees who manufacture the best-designed and uniquely printed bags for customers. A Colour printing machine that prints the pattern of the layer of the film assembles bags according to the buyers’ choice. The specialized way of printing with pattern ink in the middle layers of finished plastic packaging bags ensures that the bag will not appear to lose color phenomenon. Our printing process assures protection against temperature, humidity, and many other factors. Your product will remain fresh and will not lose its aroma.

One more plus point of our printing is that the design of the bag will catch the attention of customers quickly. We not only sell products but care for your products also.

#04) Complexes for making packaging bags and pouches

The packaging bags are manufactured step by step. The process also includes some difficulties while bringing in customized bags

Plastic packaging bags consist of diverse materials of several layers of film laminated together. The layers are laminated together by a Composite process. Our new plastic packaging bag manufacturers are using a solvent-free compounding machine that does not utilize a very small amount of adhesions and also reduces composite costs by almost 30%. Furthermore doesn’t harm the original equipment. The machine is more environmentally friendly and cost-efficient. These traits increase the production of plastic packaging bags quality another leap. We offer a large number of solutions regarding bag manufacturing. Rinpac is a client-oriented company so we comply with standards and regulations regarding the safety and hygiene of our products. You can rely on our solutions for your manufacturing difficulties.

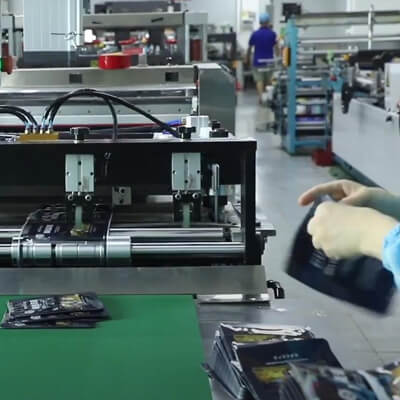

# 05) Plastic Bags and Pouches Manufacturers

The last step of packaging bags and pouches is to press two printed sheets together and cut this rolled tube into the most suitable size the specificity of our bags and pouches is that these can be customized. The protection and hygiene of your product will be assured. You’ll find the exact sized bag according to your provision. If you are hesitant to choose the perfect size and shape for your bag, you can contact our experts. They will solve your problem within a minutes and you will find the modest bag for your product.

Professional packaging Bags and Pouches Manufacturers From China

China is the superior country in the world for its manufacturing industries. The bags and pouches are equipped in China in abundance. Buyers of Chinese packaging bags and pouches are present around the globe. The secret behind this exceptional success is professional packaging bags and pouches manufacturers in the country. One of the top manufacturers in China is Rinpac. We promise premium quality bags and pouches in bulk to buyers, wholesalers, and marketers. We’ve remarkable experience and fantastic services that come only with professional manufacturers with extensive experience and knowledge.

Our products are pocket friendly. We don’t have hidden price tags, extra costs, and trading commissions. You can enjoy our services to start your own business.

Rinpac satisfies its customers with huge discounts and offers free sample bags and pouches which enhances its credibility.

One can experience the huge variety of products and options to get customized bags and pouches in abundance. We offer many sorts of products like bags and pouches for beauty products, healthcare, baby care, skin care, pet food, dry food, and medical needs.

Having a strong business reputation, outstanding client diaries, and modern machinery and equipment use, we’ve got earned fabulous recognition and a name in the manufacturing industry. Our name is our recognition.

If you want to buy elevated-quality bags and pouches in bulk, you can candid our services. We not only provide the product but respect you and your preferences. Our employees work hard to accomplish your requirements.