Home » Bags & Pouches » Spout Pouches » Custom Spout Pouches

Custom Spout Pouches

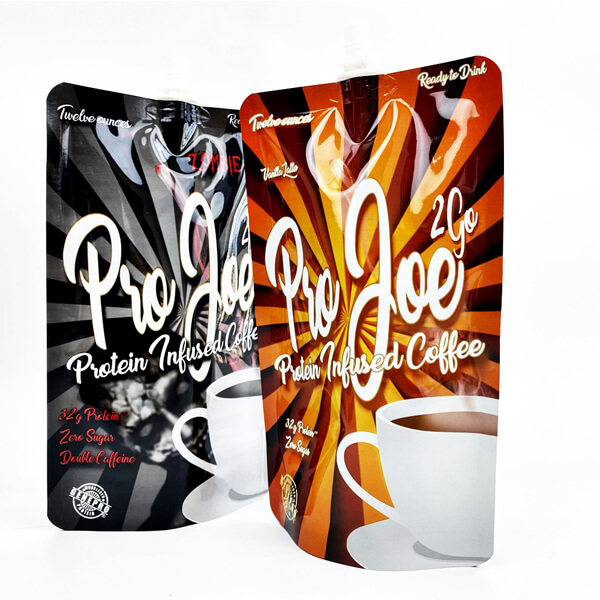

Designed as a flexible alternative to rigid containers, custom spout pouches (also known as fitment pouches) are increasingly popular with brand owners and retailers for packaging liquid, sticky and fine powder products.

Please note that we have a MOQ for our pouch. For pouches in stock, the MOQ is 500 pcs. For customized pouches, please see the MOQ as followed:

1, Digital Printing — 500 pcs

2, Gravure Printing — 5,000pcs

Rinpac assists you throughout your project: bag shape, material, thickness, capacity and printing options. Please contact us or mark your requirements on the inquiry quotation.

Order single or thousands of items at a time. Our warehouse and flexible shipping options are available for last-minute, deadline critical orders.

- Free Sample

*Customization is always available, please mark down your need in cart or just contact us.

Specification of Custom Spout Pouches

| Features | We have the capability of producing spout pouches of custom shapes and specifications. |

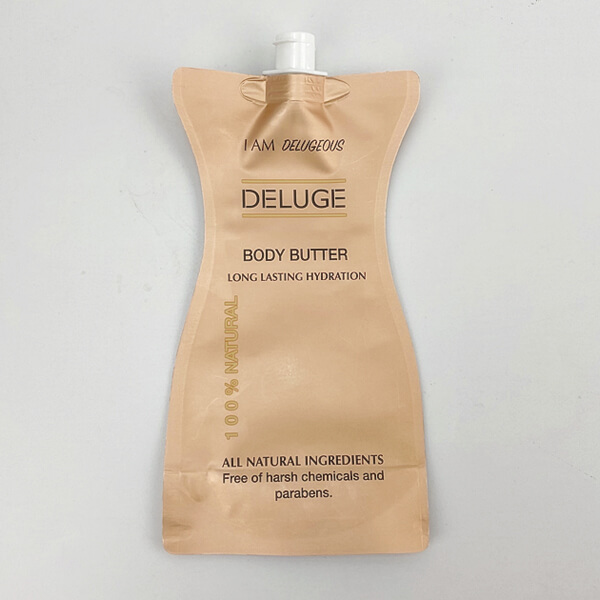

| Advantages of the custom-shaped spout pouch | Standing out from the crowd with the unique shape: to differentiate the product from the competition by having a different look and feel than the general packaging |

| Artwork Enhancement: to enhance artwork with the matched shape of the packaging | |

| Disadvantages of the custom-shaped spout pouch | Tooling charges are required for the die-cut shape |

| Per customer’s design and requirements. | |

| Customizable Features | Shapes are customized to form your unique shape of the packaging. |

| Per customer’s design and requirements. | |

| Applicable to: 3 Side Seal Flat Pouch / Stand Up Pouch |

Request A Quote - Custom Spout Pouches

Need something helped in a short time? We’ve got a plan for you.

Introduction to Custom Spout Pouches

Custom spout pouches have emerged as a versatile and innovative packaging solution, revolutionizing the way products are stored, transported, and consumed across various industries. Let’s explore the definition, purpose, and growing popularity of custom spout pouches.

Rinpac also offers the best quality cosmetic spout pouches. Get quote now.

Definition and Purpose

Custom spout pouches are flexible packaging containers with a built-in spout or nozzle, designed to dispense liquids, powders, or semi-liquids with ease and precision. These pouches typically feature a sealed bottom and sides, with the spout located at the top for convenient pouring or dispensing of the product. The primary purpose of custom spout pouches is to provide a convenient and efficient packaging solution for a wide range of products, including beverages, sauces, condiments, baby food, and personal care items. By incorporating a spout into the packaging design, custom spout pouches offer enhanced functionality, portability, and user convenience compared to traditional packaging formats.

Growing Popularity in Various Industries

Custom spout pouches have gained significant popularity across a diverse range of industries due to their numerous advantages and practical applications. In the food and beverage industry, spout pouches are widely used for packaging juices, smoothies, sauces, and liquid snacks, offering manufacturers a convenient and cost-effective packaging solution that extends product shelf life and enhances brand visibility. Similarly, in the household and personal care sectors, spout pouches are utilized for packaging detergents, cleaning solutions, shampoo, and lotions, providing consumers with easy-to-use, mess-free packaging options that are ideal for on-the-go use. The pharmaceutical and healthcare industries also utilize spout pouches for packaging liquid medications, nutritional supplements, and medical fluids, ensuring accurate dosing and safe storage of sensitive products. As consumer preferences continue to evolve towards convenience, sustainability, and user-friendly packaging solutions, custom spout pouches are expected to witness continued growth and adoption across various industries worldwide.

Advantages of Custom Spout Pouches

Custom spout pouches offer a range of advantages that make them a preferred packaging solution across various industries. Let’s explore these advantages in detail:

Convenience and Functionality

One of the primary advantages of custom spout pouches is their exceptional convenience and functionality. With a built-in spout or nozzle, these pouches allow for easy dispensing and pouring of liquids, powders, or semi-liquids without the need for additional utensils or tools. The user-friendly design of spout pouches makes them ideal for on-the-go consumption, enabling consumers to enjoy their favorite products anytime, anywhere, with minimal hassle or mess.

Cost-effectiveness

Custom spout pouches offer significant cost savings compared to traditional packaging formats such as bottles, jars, or cans. The lightweight and flexible nature of spout pouches result in reduced transportation costs, storage space requirements, and packaging material expenses. Additionally, the efficient manufacturing process of spout pouches allows for high-speed production and lower labor costs, further contributing to their overall cost-effectiveness for both manufacturers and consumers.

Sustainability

Another key advantage of custom spout pouches is their sustainability credentials. These pouches are typically made from flexible and lightweight materials such as laminated films or recyclable plastics, which require fewer resources and energy to produce compared to rigid packaging alternatives. Additionally, the compact and space-saving design of spout pouches results in reduced carbon emissions during transportation and storage, further minimizing their environmental impact. Moreover, many custom spout pouches are recyclable or made from biodegradable materials, offering eco-conscious consumers a more sustainable packaging option that aligns with their values.

In summary, custom spout pouches offer unparalleled convenience and functionality, cost-effectiveness, and sustainability, making them an attractive packaging choice for a wide range of products across diverse industries. With their innovative design and numerous benefits, custom spout pouches continue to gain popularity and market share as a preferred packaging solution in today’s competitive marketplace.

Customization Options for Spout Pouches

Custom spout pouches offer a wide range of customization options, allowing brands to tailor their packaging to meet specific product requirements and branding objectives. Let’s explore the various customization options available for spout pouches:

Material Choices

Custom spout pouches can be constructed from a variety of materials, each offering unique properties and benefits. Common materials used for spout pouches include:

Laminated Films: Flexible and versatile, laminated films provide excellent barrier properties to protect products from moisture, oxygen, and light. They are available in various thicknesses and compositions, including foil, polyethylene, polyester, and nylon, allowing brands to select the most suitable material based on product characteristics and shelf-life requirements.

Recyclable Plastics: Environmentally friendly options such as recyclable plastics are gaining popularity due to their sustainability credentials. These materials can be recycled after use, reducing environmental impact and contributing to a circular economy.

Biodegradable Materials: For brands seeking more sustainable packaging solutions, biodegradable materials derived from renewable sources such as plant-based polymers offer an eco-friendly alternative to traditional plastics. These materials break down naturally in the environment, reducing pollution and landfill waste.

Size and Shape Customization

Custom spout pouches can be tailored to specific size and shape requirements to accommodate various product volumes and packaging formats. Brands can choose from a range of standard sizes or opt for custom dimensions to fit their unique product specifications. Additionally, spout pouches can be designed with different configurations, including stand-up, flat bottom, or gusseted styles, to optimize shelf presence and storage efficiency.

Printing and Branding Options

Spout pouches offer ample surface area for branding and promotional messaging, making them an effective marketing tool for building brand awareness and attracting consumer attention. Brands can leverage advanced printing technologies such as flexography, rotogravure, or digital printing to achieve vibrant, high-quality graphics and imagery on spout pouches. Customization options for printing and branding include:

Custom Colors: Brands can select custom colors to match their brand identity and design aesthetics, creating visually appealing packaging that stands out on the shelf.

Logo Placement: Logos, brand names, and product information can be prominently displayed on spout pouches to reinforce brand recognition and communicate key messages to consumers.

Graphics and Patterns: Intricate graphics, patterns, and illustrations can be printed on spout pouches to enhance visual appeal and create a distinctive brand image.

Applications of Custom Spout Pouches

Custom spout pouches are versatile packaging solutions suitable for a wide range of industries and product categories. Let’s explore some of the key applications of custom spout pouches:

Food and Beverage Industry

Custom spout pouches are widely used in the food and beverage industry for packaging various liquid, semi-liquid, and powdered products. They are ideal for packaging:

Sauces and Condiments: Spout pouches are perfect for packaging sauces, dressings, and condiments such as ketchup, mayonnaise, and salad dressing, providing convenient dispensing and mess-free pouring.

Beverages: Spout pouches are popular for packaging beverages such as juices, smoothies, and flavored water, offering lightweight and portable packaging solutions for on-the-go consumption.

Baby Food: Spout pouches are commonly used for packaging baby food purees and snacks, providing convenient portion control and easy feeding for parents and caregivers.

Healthcare and Pharmaceuticals

In the healthcare and pharmaceutical industries, custom spout pouches are utilized for packaging a variety of medical and personal care products. They are suitable for packaging:

Liquid Medications: Spout pouches are used for packaging liquid medications such as syrups, oral suspensions, and topical solutions, offering precise dosing and easy administration for patients.

Personal Care Products: Spout pouches are employed for packaging personal care products such as shampoos, conditioners, lotions, and liquid soaps, providing mess-free dispensing and convenient storage.

Household Products

Custom spout pouches are also widely used for packaging household cleaning and maintenance products. They are suitable for packaging:

Cleaning Solutions: Spout pouches are used for packaging liquid cleaning solutions such as detergents, disinfectants, and multi-purpose cleaners, offering convenient and controlled dispensing for household chores.

Automotive Products: Spout pouches are employed for packaging automotive fluids and lubricants such as motor oil, coolant, and windshield washer fluid, providing leak-proof and space-saving packaging solutions for automotive enthusiasts and professionals.

Pet Food and Products

In the pet care industry, custom spout pouches are utilized for packaging a variety of pet food and products. They are suitable for packaging:

Pet Food: Spout pouches are used for packaging wet pet food, treats, and supplements, offering convenient portioning and freshness preservation for pet owners.

Pet Care Products: Spout pouches are employed for packaging pet care products such as shampoos, conditioners, and grooming solutions, providing mess-free dispensing and easy application for pet grooming routines.

Factors to Consider When Choosing Custom Spout Pouches

Selecting the right custom spout pouches involves considering various factors to ensure optimal packaging performance and product integrity. Here are key factors to consider:

Barrier Properties

Barrier properties play a critical role in preserving the quality and freshness of packaged products. When choosing custom spout pouches, consider the barrier properties of the packaging material to protect against external factors such as moisture, oxygen, light, and odors. Select materials with high-barrier properties to ensure extended shelf life and prevent product spoilage.

Shelf Life Requirements

Understanding the shelf life requirements of the packaged products is essential for selecting suitable custom spout pouches. Different products have varying shelf life considerations based on factors such as formulation, sensitivity to environmental factors, and storage conditions. Choose spout pouches with barrier properties and features that align with the desired shelf life of the packaged products to maintain quality and freshness over time.

Environmental Impact

In today’s environmentally conscious landscape, considering the environmental impact of packaging materials is crucial. Opt for eco-friendly materials and sustainable packaging solutions to minimize environmental footprint and support sustainability initiatives. Look for recyclable, biodegradable, or compostable options for custom spout pouches to reduce waste and promote environmental stewardship.

Compatibility with Filling and Sealing Equipment

Ensure that the selected custom spout pouches are compatible with your filling and sealing equipment to facilitate efficient production processes. Consider factors such as pouch size, shape, and material properties to ensure seamless integration with filling and sealing machinery. Compatibility with equipment will help streamline production operations and minimize downtime.

Branding and Design Requirements

Custom spout pouches offer ample opportunities for branding and design customization to enhance product visibility and consumer engagement. Consider your branding requirements, including logo placement, color schemes, and graphic design elements, when selecting pouch options. Choose pouches that provide optimal printing surfaces and customization options to create eye-catching packaging that reinforces brand identity and attracts consumer attention.

Cost Considerations

Balancing packaging performance with cost considerations is essential for maximizing value and profitability. Evaluate the overall cost of custom spout pouches, taking into account factors such as material costs, production volume, printing expenses, and shipping logistics. Compare pricing from different suppliers and assess the total cost of ownership to ensure cost-effectiveness while meeting quality and performance requirements.

By carefully considering these factors when choosing custom spout pouches, brands can select packaging solutions that meet their specific needs, enhance product appeal, and deliver superior value to consumers.

Design Considerations for Custom Spout Pouches

Design plays a crucial role in the success of custom spout pouches, influencing both consumer appeal and practical functionality. Here are key design considerations to keep in mind when selecting and creating custom spout pouches:

Visual Appeal

The visual appeal of custom spout pouches is vital for attracting consumer attention and differentiating products on the shelf. Consider incorporating vibrant colors, captivating graphics, and eye-catching designs that resonate with your target audience. Engaging visual elements can enhance product visibility and draw consumers’ interest, ultimately driving purchase decisions.

Practicality

While aesthetics are important, it’s equally essential to prioritize practicality in the design of custom spout pouches. Optimize pouch dimensions, shape, and spout placement for ergonomic handling and easy dispensing. Ensure that the pouch design allows for efficient filling, sealing, and storage, minimizing production and logistical challenges. Practical design features enhance user experience and convenience, fostering positive consumer perceptions of the brand.

Brand Representation

Custom spout pouches serve as a tangible representation of your brand identity and values. Use design elements such as logos, taglines, and brand colors to reinforce brand recognition and create a cohesive brand experience. Align the visual aesthetics of the pouch design with your brand’s personality and positioning to establish a strong brand presence on the packaging. Consistent brand representation builds trust and loyalty among consumers, encouraging repeat purchases and brand advocacy.

Functionality

Beyond visual appeal, prioritize functionality in the design of custom spout pouches to ensure seamless usability for consumers. Choose spout configurations and closure mechanisms that facilitate easy opening, dispensing, and resealing, enhancing user convenience and product freshness. Consider incorporating features such as tear notches, handles, and ergonomic grips to improve handling and usability. Functional design elements contribute to overall product satisfaction and consumer delight.

Sustainability

Incorporate sustainability considerations into the design of custom spout pouches to align with environmentally conscious consumer preferences. Opt for eco-friendly materials, minimalist designs, and recyclable packaging options to reduce environmental impact and support sustainable practices. Communicate sustainability initiatives and certifications on the packaging to resonate with eco-conscious consumers and differentiate your brand in the market.

Regulatory Compliance

Ensure that the design of custom spout pouches complies with regulatory requirements and industry standards for product safety and labeling. Adhere to packaging regulations related to food contact materials, product information, and warning labels to maintain legal compliance and consumer trust. Work with experienced packaging suppliers and design professionals to navigate regulatory complexities and ensure compliance throughout the design process.

By carefully considering these design considerations, brands can create custom spout pouches that not only captivate consumers with visually appealing packaging but also deliver practical functionality, reinforce brand identity, and support sustainability initiatives.

Manufacturing Process of Custom Spout Pouches

The production of custom spout pouches involves a series of carefully orchestrated steps to transform raw materials into finished packaging solutions. Here’s an overview of the manufacturing process:

Materials Sourcing

The manufacturing process begins with materials sourcing, where high-quality packaging materials are selected to meet the specific requirements of the custom spout pouches. These materials typically include barrier films such as PET, PE, or aluminum foil, which provide protection against moisture, oxygen, and light. Sourcing sustainable and eco-friendly materials is increasingly prioritized to align with consumer preferences for environmentally conscious packaging solutions.

Printing and Lamination

Once the materials are sourced, they undergo printing and lamination to apply graphics, branding elements, and product information onto the packaging substrate. Advanced printing technologies such as flexography, gravure, or digital printing are utilized to achieve vibrant colors, intricate designs, and precise graphics reproduction on the pouch surface. After printing, the packaging materials are laminated together to create a multilayered structure that enhances barrier properties and durability.

Spout Insertion and Sealing

The next step in the manufacturing process involves spout insertion and sealing, where the spout components are integrated into the pouch design and securely sealed to ensure leak-proof functionality. Automated machinery is used to precisely position the spout on the pouch body, followed by heat sealing or ultrasonic welding to bond the spout to the packaging material. This sealing process creates a hermetic seal that prevents product leakage and maintains product freshness throughout the shelf life.

Quality Control and Inspection

Throughout the manufacturing process, rigorous quality control and inspection procedures are implemented to ensure that each custom spout pouch meets the highest standards of quality, consistency, and performance. Quality control measures may include visual inspections, dimensional checks, and seal integrity tests to identify any defects or imperfections in the packaging. Strict adherence to quality standards ensures that only defect-free pouches are released for packaging and distribution.

Packaging and Distribution

Once the custom spout pouches have undergone thorough quality assurance checks, they are packaged and prepared for distribution to customers. The pouches may be bundled into batches, boxed, or palletized for transportation to various destinations. Efficient logistics and supply chain management ensure timely delivery of the finished pouches to clients, where they are filled with product and introduced into the market for consumer purchase.

By following these meticulous manufacturing processes, manufacturers can produce custom spout pouches that offer superior quality, functionality, and visual appeal, meeting the diverse packaging needs of various industries and brands.

Future Trends in Custom Spout Pouches

As the packaging industry continues to evolve and adapt to changing consumer preferences and market demands, several key trends are shaping the future of custom spout pouches. Here’s a glimpse into the future of this innovative packaging solution:

Innovations in Materials

One of the future trends in custom spout pouches is the continuous innovation in materials. Manufacturers are exploring new sustainable materials and advanced barrier films that offer enhanced protection, functionality, and eco-friendliness. Bio-based polymers, compostable films, and recyclable materials are expected to gain traction, catering to the growing demand for environmentally responsible packaging solutions. These innovations in materials will enable brands to reduce their carbon footprint and meet sustainability goals while maintaining product freshness and quality.

Technological Advancements

Advancements in technology are poised to revolutionize the manufacturing process of custom spout pouches, driving efficiency, precision, and customization capabilities. Cutting-edge printing technologies, such as digital printing and smart packaging solutions, will enable brands to create highly personalized and interactive packaging experiences. Automation and robotics will streamline production processes, reducing lead times and enhancing production scalability. Additionally, digitalization and data-driven insights will empower brands to optimize packaging designs, improve supply chain visibility, and engage consumers through innovative packaging solutions.

Market Projections

Market projections indicate continued growth and expansion opportunities for custom spout pouches across various industries and regions. With increasing consumer demand for convenient, portable, and on-the-go packaging formats, custom spout pouches are expected to witness heightened adoption in food and beverage, personal care, pharmaceuticals, and household products sectors. As e-commerce continues to flourish, the demand for flexible, lightweight, and durable packaging solutions like spout pouches will soar, driving market growth and investment in manufacturing capabilities.

Sustainability and Circular Economy

The emphasis on sustainability and the circular economy will remain a prominent trend in the future of custom spout pouches. Brands will prioritize recyclability, biodegradability, and lifecycle assessments in packaging design and material selection to minimize environmental impact and meet regulatory requirements. Collaborative initiatives between industry stakeholders, government bodies, and consumers will drive the development of closed-loop recycling systems and sustainable packaging solutions that promote resource efficiency and waste reduction.

Consumer-Centric Packaging

Consumer-centric packaging will be a driving force in the future of custom spout pouches, with brands focusing on consumer convenience, safety, and engagement. Innovative features such as resealable closures, ergonomic designs, and interactive packaging elements will cater to evolving consumer lifestyles and preferences. Personalized packaging experiences, including augmented reality, QR codes, and product storytelling, will create emotional connections with consumers and foster brand loyalty.

By embracing these future trends and innovations, manufacturers and brands can unlock new opportunities, address emerging challenges, and stay ahead in the dynamic landscape of custom spout pouches.

Environmental Impact of Custom Spout Pouches

As sustainability becomes increasingly important in the packaging industry, understanding the environmental impact of custom spout pouches is crucial. Let’s explore how these innovative packaging solutions compare with traditional packaging and examine recycling and disposal options:

Comparison with Traditional Packaging

Custom spout pouches offer several environmental advantages compared to traditional packaging formats such as rigid containers, glass bottles, and metal cans. Firstly, spout pouches are typically made from lightweight and flexible materials, resulting in reduced material usage and transportation emissions. Their compact and stackable design minimizes storage space and shipping costs, further lowering carbon footprint throughout the supply chain. Additionally, the customizable nature of spout pouches allows for optimal product-to-package ratio, reducing food waste and environmental impact.

Recycling and Disposal Options

Recycling options for custom spout pouches depend on the specific materials used in their construction. Many spout pouches are made from multilayered films that can be challenging to recycle through traditional municipal recycling programs. However, advancements in recycling technologies and the development of specialized recycling facilities are improving the recyclability of flexible packaging materials. Some manufacturers offer recyclable or compostable options for spout pouches, addressing concerns about end-of-life disposal.

Disposal options for custom spout pouches vary based on local waste management infrastructure and regulations. While some regions may accept spout pouches for recycling alongside other plastic packaging, others may classify them as non-recyclable waste. It’s essential for consumers to check with their local recycling facilities or waste management authorities to determine the appropriate disposal method for spout pouches. In areas where recycling is not feasible, responsible disposal methods such as waste-to-energy incineration or landfill diversion may be employed to minimize environmental impact.

Embracing Sustainable Practices

To further enhance the environmental sustainability of custom spout pouches, manufacturers and brands are embracing sustainable practices throughout the packaging lifecycle. This includes reducing packaging material waste through lightweighting and optimization, prioritizing the use of renewable and recyclable materials, and investing in closed-loop recycling systems. Collaboration across the packaging value chain, from raw material suppliers to end-of-life recyclers, is essential to drive innovation and advance sustainable packaging solutions.

In conclusion, while custom spout pouches offer several environmental benefits compared to traditional packaging, there are still challenges to address regarding recyclability and disposal. By investing in sustainable materials, technologies, and practices, the packaging industry can minimize environmental impact and contribute to a more circular economy.

Regulatory Compliance in Custom Spout Pouches

Ensuring compliance with food safety regulations and packaging standards is paramount in the manufacturing and distribution of custom spout pouches. Let’s delve into the regulatory landscape governing these aspects:

Food Safety Regulations

Custom spout pouches intended for packaging food products must adhere to stringent food safety regulations to safeguard consumer health and well-being. These regulations encompass various aspects of food contact materials, including packaging materials, printing inks, adhesives, and closures. In the United States, the Food and Drug Administration (FDA) regulates food contact materials under the Federal Food, Drug, and Cosmetic Act (FD&C Act) and the Food Contact Substance Notification (FCN) program. The European Union (EU) follows similar regulations under the framework of the European Food Safety Authority (EFSA) and the Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food.

Key considerations for compliance with food safety regulations include:

-

Material Safety: Custom spout pouch materials must be evaluated for their safety and suitability for food contact, ensuring they do not leach harmful substances into the packaged food.

-

Migration Testing: Manufacturers conduct migration testing to assess the transfer of substances from packaging materials to food under various conditions, such as temperature and duration of contact.

-

Compositional Compliance: Packaging materials must comply with specific compositional requirements and restrictions on substances of concern, including heavy metals, phthalates, and Bisphenol A (BPA).

-

Good Manufacturing Practices (GMP): Adherence to GMP principles is essential to maintain hygiene, cleanliness, and quality control throughout the manufacturing process, minimizing the risk of contamination.

Packaging Standards

In addition to food safety regulations, custom spout pouches must meet established packaging standards to ensure product integrity, functionality, and consumer satisfaction. These standards encompass dimensions, closures, barrier properties, and performance requirements for different packaging applications.

Internationally recognized packaging standards include:

-

ISO 9001: Quality Management Systems (QMS) certification ensures consistency in manufacturing processes, product quality, and customer satisfaction.

-

ISO 22000: Food Safety Management Systems (FSMS) certification addresses food safety hazards throughout the food chain, including packaging materials and processes.

-

ASTM D3475: Standard Test Method for Sampling and Testing Flexible Barrier Packaging provides guidelines for testing the barrier properties of flexible packaging materials, including spout pouches.

-

EN 13427: European standard for packaging requirements and acceptance criteria, covering aspects such as material compatibility, closure integrity, and environmental impact.

By adhering to these food safety regulations and packaging standards, manufacturers can demonstrate their commitment to product safety, quality, and compliance with regulatory requirements. Continuous monitoring, testing, and documentation of compliance ensure the integrity and reliability of custom spout pouches throughout their lifecycle.

Cost Analysis of Custom Spout Pouches

Conducting a comprehensive cost analysis is essential for evaluating the economic viability of custom spout pouches compared to other packaging options. Let’s delve into the key considerations and factors impacting the cost-effectiveness of spout pouch packaging:

Comparing Costs with Other Packaging Options

Custom spout pouches offer several cost advantages compared to traditional packaging formats such as rigid containers, glass bottles, and metal cans. Here’s a breakdown of cost considerations:

Material Costs: Spout pouches are typically made from lightweight and flexible materials, such as laminated films or multilayered plastics, which are often more cost-effective than rigid packaging materials like glass or metal. The lower material weight also translates to reduced shipping costs, especially for bulk quantities.

Production Costs: The manufacturing process for custom spout pouches involves fewer production steps and less energy-intensive processes compared to rigid packaging options. This results in lower production costs and faster turnaround times, contributing to overall cost savings.

Storage and Transportation: Spout pouches’ flexible and stackable design minimizes storage space requirements and facilitates efficient transportation, reducing warehousing and logistics expenses. Moreover, their lightweight nature lowers shipping costs, especially for long-distance transportation.

Long-Term Savings

While the initial investment in custom spout pouches may be comparable or slightly higher than traditional packaging options, the long-term savings and benefits outweigh the upfront costs:

Reduced Material Waste: Spout pouches optimize product-to-package ratio, minimizing material waste and reducing packaging costs over time. Additionally, their flexible design allows for efficient use of shelf space, maximizing retail display and reducing restocking frequency.

Extended Shelf Life: The barrier properties of spout pouches help preserve product freshness and extend shelf life, reducing food waste and associated costs. This not only enhances product quality and customer satisfaction but also minimizes the need for promotional discounts or markdowns due to spoilage.

Brand Differentiation: Custom spout pouches offer ample opportunities for branding and visual appeal, enabling brands to stand out on retail shelves and attract consumer attention. The enhanced brand visibility and perceived value can lead to increased sales and market share, offsetting initial packaging costs.

Environmental Savings: Spout pouches’ lightweight and flexible design result in lower carbon emissions during transportation and reduced environmental impact compared to rigid packaging options. Embracing sustainable packaging practices can further enhance brand reputation and customer loyalty, driving long-term business success.

In conclusion, while custom spout pouches may entail slightly higher initial costs than traditional packaging options, their long-term savings potential, coupled with numerous operational and environmental benefits, make them a cost-effective choice for businesses across various industries.

Customer Satisfaction and Market Demand

Understanding consumer preferences and staying attuned to market demand are paramount for businesses seeking sustained success in today’s competitive landscape. Let’s explore the factors influencing customer satisfaction and market demand in the context of custom spout pouches:

Consumer Preferences

Convenience and Functionality:

- Ease of Use: Consumers value packaging that offers convenience and simplicity, and custom spout pouches excel in this regard. The user-friendly design, with a resealable spout and easy-pour functionality, enhances convenience and minimizes mess, resonating well with busy lifestyles.

- Portability: Portable packaging solutions are increasingly favored by consumers who prioritize on-the-go convenience. Spout pouches’ lightweight and compact design make them ideal for travel, outdoor activities, and packed lunches, catering to modern consumer preferences.

Environmental Considerations:

- Sustainability: Growing environmental consciousness has spurred demand for eco-friendly packaging options. Custom spout pouches, often made from recyclable materials and offering reduced material waste, align with consumers’ sustainability expectations, fostering positive brand perception and loyalty.

Market Research Insights

Emerging Trends:

- Health and Wellness: With an increasing focus on health-conscious consumption, there’s a rising demand for packaging that preserves product freshness and quality. Custom spout pouches, with their superior barrier properties and extended shelf life, cater to health-conscious consumers seeking nutritious and minimally processed products.

- Convenience Foods: The rise of convenience foods and ready-to-drink beverages has fueled demand for packaging solutions that offer both convenience and freshness. Spout pouches are well-suited for a diverse range of products, including soups, sauces, baby food, and beverages, meeting the evolving needs of busy consumers.

Market Expansion:

- Diversification: Custom spout pouches are increasingly adopted across various industries beyond food and beverage, including personal care, household products, and pet care. As manufacturers recognize the versatility and adaptability of spout pouch packaging, the market continues to expand, driving innovation and market penetration.

In conclusion, by aligning with consumer preferences for convenience, sustainability, and product freshness, custom spout pouches have garnered significant market demand and consumer satisfaction. Businesses that leverage these insights to tailor their packaging solutions can capitalize on growing opportunities and foster enduring customer relationships.

Tips for Effective Implementation

Implementing custom spout pouches successfully requires careful planning, collaboration, and attention to detail. Here are some valuable tips to ensure a seamless and efficient implementation process:

Partnering with Experienced Suppliers

Supplier Selection:

- Research and Due Diligence: Conduct thorough research to identify reputable suppliers with proven expertise in custom spout pouch manufacturing. Look for suppliers with a track record of delivering high-quality products and excellent customer service.

- Evaluate Capabilities: Assess the supplier’s manufacturing capabilities, including equipment, technology, and production capacity. Choose a supplier equipped to meet your specific packaging requirements and volume demands.

Collaboration and Communication:

- Open Dialogue: Foster open communication with your chosen supplier to discuss project goals, timelines, and expectations. Collaborate closely throughout the development process to ensure alignment and address any concerns or challenges proactively.

- Feedback Mechanisms: Establish clear feedback mechanisms to facilitate ongoing communication and address any issues promptly. Encourage constructive feedback from both parties to drive continuous improvement and optimize outcomes.

Testing and Quality Control Measures

Prototype Development:

- Prototype Testing: Work closely with your supplier to develop prototype spout pouches for thorough testing and evaluation. Conduct comprehensive testing to assess functionality, durability, and compatibility with your product.

- Iterative Refinement: Use feedback from prototype testing to refine design elements, optimize performance, and address any potential issues or shortcomings. Iterate as needed to achieve the desired balance of functionality and aesthetics.

Quality Assurance:

- Stringent Standards: Establish stringent quality assurance protocols to uphold product integrity and consistency throughout the manufacturing process. Implement rigorous quality control measures at every stage, from material sourcing to final inspection.

- Compliance and Certification: Ensure compliance with industry regulations and standards governing packaging materials and food safety. Work with suppliers who adhere to relevant certifications and undergo regular audits to uphold quality and compliance.

By partnering with experienced suppliers, fostering open communication, and prioritizing testing and quality control measures, businesses can effectively implement custom spout pouches and realize the full range of benefits they offer.

Conclusion

In summary, custom spout pouches offer a multitude of benefits that make them a preferred packaging solution across various industries. From enhanced convenience and functionality to sustainability and versatility, spout pouches address key consumer preferences while meeting stringent industry standards. Their sturdy construction, advanced barrier properties, and eye-catching design contribute to improved shelf presence, product protection, and brand visibility.

Looking ahead, the future outlook for custom spout pouches appears promising. With ongoing advancements in materials, manufacturing technologies, and market demand, spout pouches are poised to continue their upward trajectory. As businesses increasingly prioritize sustainability, innovation, and consumer-centric packaging solutions, custom spout pouches are well-positioned to meet evolving needs and preferences.

By leveraging the benefits of custom spout pouches and embracing opportunities for collaboration, innovation, and quality assurance, businesses can drive growth, enhance customer satisfaction, and stay ahead of the curve in a competitive market landscape.

Rinpac offers the top quality bags and pouches. Get quote now. Thanks

Important Terms

Custom spout pouches wholesale: Refers to spout pouch packaging that is tailored to specific requirements such as size, shape, material, and design, and is available for purchase in bulk quantities at wholesale prices. These pouches typically feature a spout for easy dispensing and are customizable to meet the needs of various industries and products.

Custom spout pouches with logo: These are spout pouches that are personalized with a specific logo or branding elements of a company or product. The logo is typically printed onto the pouches using techniques like printing or labeling, allowing businesses to enhance brand visibility and recognition through their packaging.

Custom spout pouches for food: Spout pouches specifically designed and manufactured for packaging food products. These pouches offer advantages such as ease of storage, transportation, and dispensing, while also providing protection from moisture, oxygen, and other external factors that can affect food quality and shelf life.

Liquid spout bags wholesale: Refers to flexible packaging solutions designed for liquids, such as beverages, sauces, oils, and more, available for purchase in bulk quantities at wholesale prices. These bags feature a spout for convenient pouring or dispensing of the liquid contents and are suitable for various industries including food and beverage, household products, and personal care.

Pouches with spouts: Flexible packaging containers equipped with a spout for easy pouring or dispensing of contents. These pouches are commonly used for packaging a wide range of products including liquids, powders, gels, and semi-solid substances. They offer convenience, portability, and reduced material usage compared to traditional rigid packaging options.