Home » Bags & Pouches » Spout Pouches » Aluminium Spout Pouch

Aluminium Spout Pouch

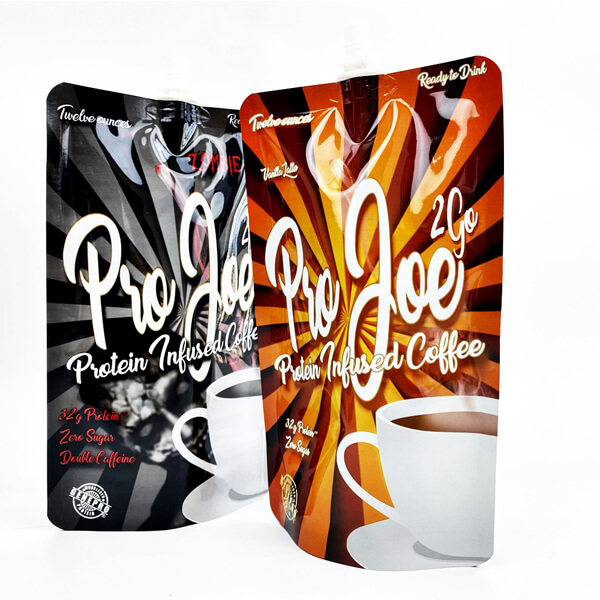

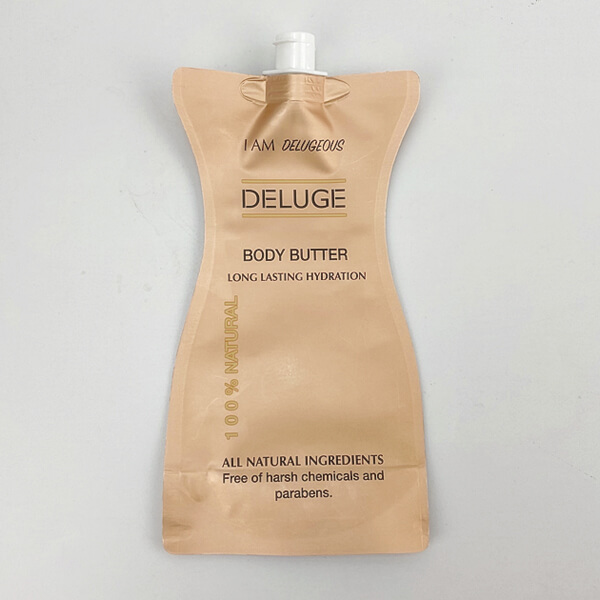

Designed as a flexible alternative to rigid containers, aluminium spout pouches (also known as fitment pouches) are increasingly popular with brand owners and retailers for packaging liquid, sticky and fine powder products.

Please note that we have a MOQ for our pouch. For pouches in stock, the MOQ is 500 pcs. For customized pouches, please see the MOQ as followed:

1, Digital Printing — 500 pcs

2, Gravure Printing — 5,000pcs

Rinpac assists you throughout your project: bag shape, material, thickness, capacity and printing options. Please contact us or mark your requirements on the inquiry quotation.

Order single or thousands of items at a time. Our warehouse and flexible shipping options are available for last-minute, deadline critical orders.

- Free Sample

*Customization is always available, please mark down your need in cart or just contact us.

Specification of Aluminium Spout Pouch

| Features | We have the capability of producing spout pouches of custom shapes and specifications. |

| Advantages of the custom-shaped spout pouch | Standing out from the crowd with the unique shape: to differentiate the product from the competition by having a different look and feel than the general packaging |

| Artwork Enhancement: to enhance artwork with the matched shape of the packaging | |

| Disadvantages of the custom-shaped spout pouch | Tooling charges are required for the die-cut shape |

| Per customer’s design and requirements. | |

| Customizable Features | Shapes are customized to form your unique shape of the packaging. |

| Per customer’s design and requirements. | |

| Applicable to: 3 Side Seal Flat Pouch / Stand Up Pouch |

Request A Quote - Aluminium Spout Pouch

Need something helped in a short time? We’ve got a plan for you.

Introduction to Aluminum Spout Pouches

Aluminum spout pouches represent a cutting-edge packaging solution that combines the convenience of spout pouches with the durability and barrier properties of aluminum foil. These innovative pouches are increasingly popular across various industries due to their ability to preserve product freshness, extend shelf life, and enhance brand visibility. In this article, we will explore the unique features, benefits, and applications of aluminum spout pouches, as well as their impact on the packaging landscape.

Buy top quality Aluminium Foil Spout Pouch from Rinpac at affordable wholesale prices.

Advantages of Aluminum Spout Pouches

Aluminum spout pouches offer a range of benefits that make them an ideal packaging choice for a wide variety of products. Here are some of the key advantages:

Lightweight and Durable: Despite their lightweight nature, aluminum spout pouches are incredibly durable, providing protection against punctures, tears, and other forms of damage during handling and transportation. This combination of lightness and strength makes them suitable for both retail and e-commerce environments, where durability and portability are essential.

Excellent Barrier Properties: Aluminum foil is known for its exceptional barrier properties, which effectively block out light, oxygen, moisture, and other contaminants that can compromise the quality and freshness of packaged products. This barrier protection helps to extend the shelf life of perishable goods, ensuring that they remain fresh and flavorful for longer periods.

Versatility in Packaging: Aluminum spout pouches offer versatility in packaging design and functionality. They can be customized in various shapes, sizes, and configurations to accommodate different product types and packaging requirements. Additionally, the spout feature allows for easy dispensing and resealing, making them suitable for a wide range of liquid and semi-liquid products, including beverages, sauces, creams, and more.

Applications of Aluminum Spout Pouches

Aluminum spout pouches find extensive use across various industries due to their versatility, durability, and excellent barrier properties. Some common applications include:

Food and Beverage Industry: Aluminum spout pouches are widely used for packaging a variety of food and beverage products such as sauces, condiments, soups, juices, energy drinks, and dairy products. The superior barrier properties of aluminum foil help to preserve the freshness and flavor of perishable items, while the spout feature facilitates convenient pouring and dispensing.

Cosmetics and Personal Care Products: In the cosmetics and personal care industry, aluminum spout pouches are favored for packaging a range of liquid and semi-liquid products such as shampoos, conditioners, lotions, creams, and shower gels. The lightweight and flexible nature of the pouches, combined with their ability to protect sensitive formulations from external contaminants, make them an ideal choice for beauty and skincare products.

Pharmaceuticals: Aluminum spout pouches are also utilized in the pharmaceutical sector for packaging medications, vitamins, supplements, and other healthcare products. The hermetic seal provided by the pouches ensures product integrity and helps to extend the shelf life of pharmaceutical formulations. Additionally, the lightweight and portable design of spout pouches makes them suitable for travel-friendly packaging options.

These are just a few examples of the diverse applications of aluminum spout pouches across different industries. Their adaptability, combined with their protective and convenient packaging features, makes them a preferred choice for a wide range of products.

Customization Options for Aluminum Spout Pouches

Aluminum spout pouches offer a high degree of flexibility and customization, allowing brands to create packaging solutions that align with their specific requirements and branding objectives. Some key customization options include:

Size and Shape: Aluminum spout pouches can be tailored to suit different product volumes and packaging dimensions. Whether it’s small single-serving pouches or larger family-sized packs, manufacturers can customize the size and shape of the pouches to accommodate various product quantities and packaging needs.

Printing and Branding: One of the primary advantages of aluminum spout pouches is their excellent printability, which enables vibrant and eye-catching graphics to be applied directly onto the pouch surface. Brands can leverage this printing capability to showcase their logos, product information, promotional messages, and branding elements. Custom printing options include flexographic printing, rotogravure printing, and digital printing, allowing for intricate designs and high-quality graphics.

Additional Features: In addition to size, shape, and printing, aluminum spout pouches can be enhanced with various additional features to meet specific packaging requirements. Some common options include:

- Spout Types: Brands can choose from different spout types such as screw caps, flip caps, or press-to-close caps, depending on the product viscosity and dispensing preferences.

- Zipper Closure: For resealable functionality, zipper closures can be added to aluminum spout pouches, allowing consumers to open and close the packaging multiple times while maintaining product freshness.

- Hang Holes: Hang holes or Euro slots can be incorporated into the pouch design to facilitate vertical display and merchandising on store shelves, maximizing retail visibility.

By offering a wide range of customization options, aluminum spout pouches enable brands to create unique and visually appealing packaging solutions that resonate with consumers and reinforce brand identity. Whether it’s through custom sizing, eye-catching graphics, or additional features, the versatility of aluminum spout pouches allows brands to differentiate their products and stand out in the competitive marketplace.

Environmental Impact of Aluminum Spout Pouches

Aluminum spout pouches are gaining recognition not only for their functionality and versatility but also for their positive environmental attributes. Here’s how aluminum spout pouches contribute to sustainable packaging solutions:

Recyclability: Aluminum spout pouches are highly recyclable, offering a valuable opportunity to minimize waste and conserve resources. Aluminum is a material with high recyclability, meaning that used pouches can be collected, processed, and recycled into new products with relatively low energy consumption. By participating in recycling programs or initiatives, consumers can help divert aluminum spout pouches from landfills and promote a circular economy where materials are reused and repurposed.

Reduced Carbon Footprint: Compared to traditional packaging materials like glass or rigid plastics, aluminum spout pouches offer significant environmental benefits in terms of transportation and energy consumption. Aluminum is lightweight yet durable, allowing for reduced material usage and lower shipping weights. This lightweight nature translates to fewer emissions during transportation, contributing to a lower carbon footprint throughout the supply chain. Additionally, the recyclability of aluminum means that recycled content can be incorporated into new pouches, further reducing the need for virgin materials and associated environmental impacts.

Sustainable Packaging Solutions: Aluminum spout pouches are increasingly recognized as part of the broader shift towards sustainable packaging solutions. As consumers become more environmentally conscious and demand eco-friendly alternatives, brands are turning to aluminum spout pouches as a sustainable packaging option. These pouches offer a compelling combination of recyclability, reduced material usage, and energy efficiency, aligning with brands’ sustainability goals and meeting consumer expectations for responsible packaging choices.

By choosing aluminum spout pouches for their packaging needs, brands can demonstrate their commitment to sustainability and contribute to a greener future. Through collaboration with consumers, recycling facilities, and industry stakeholders, aluminum spout pouches can play a significant role in advancing sustainable packaging practices and reducing environmental impact across the packaging value chain.

Innovations in Aluminum Spout Pouch Technology

As the demand for sustainable and efficient packaging solutions continues to grow, manufacturers are innovating in aluminum spout pouch technology to meet the evolving needs of consumers and businesses. Here are some notable advancements shaping the future of aluminum spout pouches:

Enhanced Barrier Properties: One area of innovation in aluminum spout pouch technology focuses on enhancing the barrier properties of the pouches to prolong product freshness and shelf life. Manufacturers are developing advanced multi-layer structures with specialized barrier films that provide superior protection against moisture, oxygen, and light. These enhanced barrier properties help preserve the quality and integrity of the packaged contents, making aluminum spout pouches suitable for a wide range of products, including food, beverages, and pharmaceuticals.

Convenient Dispensing Features: Another innovation in aluminum spout pouch technology involves the integration of convenient dispensing features that improve user experience and product convenience. Manufacturers are incorporating resealable spouts, flip-top caps, and ergonomic designs to facilitate easy pouring, dispensing, and resealing of the pouches. These user-friendly features enhance the functionality and practicality of aluminum spout pouches, making them ideal for on-the-go consumption and household use.

Eco-Friendly Materials: In response to growing environmental concerns, manufacturers are exploring eco-friendly materials and sustainable manufacturing processes for aluminum spout pouches. This includes the development of bio-based films, compostable laminates, and recyclable components that reduce the environmental impact of packaging while maintaining performance and functionality. By incorporating eco-friendly materials into aluminum spout pouches, manufacturers can offer more sustainable packaging options to environmentally conscious consumers and businesses.

Overall, these innovations in aluminum spout pouch technology represent significant advancements in packaging design, functionality, and sustainability. By leveraging enhanced barrier properties, convenient dispensing features, and eco-friendly materials, aluminum spout pouches are poised to meet the evolving needs of the market while reducing environmental impact and contributing to a more sustainable packaging ecosystem.

How to Choose the Right Aluminum Spout Pouch Supplier

Selecting the right aluminum spout pouch supplier is crucial to ensuring the success of your packaging endeavors. Here are key factors to consider when making your decision:

Quality Assurance: When choosing an aluminum spout pouch supplier, prioritize those with robust quality assurance processes in place. Look for suppliers who adhere to industry standards and regulations for manufacturing aluminum pouches. This includes conducting thorough quality control checks at various stages of production to ensure the pouches meet your specifications and requirements. Additionally, inquire about the supplier’s track record of delivering high-quality products and their commitment to continuous improvement in product quality.

Production Capacity: Evaluate the production capacity of potential aluminum spout pouch suppliers to ensure they can meet your demand and timelines. Consider factors such as production volume, lead times, and flexibility in accommodating fluctuating order sizes. A supplier with ample production capacity and efficient manufacturing processes can provide you with timely deliveries and scalability to support your business growth. Moreover, inquire about the supplier’s ability to handle custom orders and accommodate special requirements, such as unique designs or printing specifications.

Customer Service: Excellent customer service is essential for establishing a successful partnership with an aluminum spout pouch supplier. Seek suppliers who prioritize open communication, responsiveness, and transparency throughout the procurement process. A reliable supplier should be accessible and proactive in addressing any inquiries, concerns, or issues that may arise. Additionally, consider the supplier’s willingness to provide technical support, guidance on product selection, and assistance with customization options. A supplier who values customer satisfaction and builds strong relationships with clients can contribute to a positive and mutually beneficial partnership.

By carefully evaluating these factors and conducting thorough research, you can choose the right aluminum spout pouch supplier that aligns with your packaging needs and business objectives.

Conclusion

In conclusion, aluminum spout pouches offer numerous advantages in terms of durability, barrier properties, and versatility, making them a popular choice across various industries such as food and beverage, cosmetics, and pharmaceuticals. With their lightweight design and excellent barrier properties, aluminum spout pouches provide convenient and sustainable packaging solutions for a wide range of products.

Furthermore, ongoing innovations in aluminum spout pouch technology, such as enhanced barrier properties and convenient dispensing features, continue to drive advancements in packaging solutions. These innovations, coupled with a growing emphasis on sustainability, contribute to the increasing adoption of aluminum spout pouches in the market.

Successful case studies highlight the effectiveness of aluminum spout pouches in meeting the diverse packaging needs of businesses and brands. By selecting the right aluminum spout pouch supplier based on factors such as quality assurance, production capacity, and customer service, businesses can ensure the success of their packaging endeavors and establish long-term partnerships.

In summary, aluminum spout pouches represent a versatile and sustainable packaging solution with a wide range of applications. By embracing technological advancements and partnering with reliable suppliers, businesses can leverage the benefits of aluminum spout pouches to enhance their packaging strategies and meet the evolving demands of consumers and the market.

Looking for bags and pouches for your business. Contact us for more details.

FAQs

What are spout pouches made of?

Spout pouches are typically made from multiple layers of materials, including plastic films such as polyethylene (PE), polypropylene (PP), and sometimes aluminum foil. These layers are laminated together to create a flexible yet sturdy pouch.

How do you make a spout pouch?

Spout pouches are made through a process called laminating. This involves sandwiching multiple layers of materials together, including plastic films and sometimes aluminum foil, and then sealing them to form the pouch shape. The spout is then attached to the pouch through heat sealing or other methods.

What is the use of Aluminum pouch?

Aluminum pouches are commonly used for packaging items that require protection from moisture, oxygen, and light. They are often used for food items, pharmaceuticals, and other products that need to remain fresh and stable.

What are the disadvantages of spout pouches?

Some disadvantages of spout pouches include potential puncture or tearing, limited reusability compared to rigid containers, and difficulty in recycling due to the combination of different materials in their construction.

What are the benefits of aluminum?

Aluminum offers numerous benefits as a packaging material, including its lightweight nature, ability to protect against moisture, oxygen, and light, recyclability, and versatility in design.

Why aluminum is the best packaging?

Aluminum is often considered one of the best packaging materials due to its excellent barrier properties, recyclability, lightweight nature, and versatility. It effectively protects products from moisture, oxygen, and light, while also being eco-friendly.

Is aluminum packaging safe?

Yes, aluminum packaging is generally considered safe for packaging food and pharmaceuticals. It is inert, meaning it does not react with the contents of the package, and is approved for use by regulatory agencies around the world.

Why is aluminum used in food?

Aluminum is used in food packaging because it provides an effective barrier against moisture, oxygen, and light, helping to preserve the freshness and quality of the food. It is also lightweight, recyclable, and cost-effective.

How thick is an aluminum can?

Aluminum cans typically have a thickness ranging from about 0.1 to 0.2 millimeters (0.004 to 0.008 inches), depending on the specific application and manufacturer.

What are the main properties of aluminum?

The main properties of aluminum include its lightweight nature, corrosion resistance, excellent conductivity, recyclability, and malleability, allowing it to be easily formed into various shapes.

Is aluminum packaging eco-friendly?

Yes, aluminum packaging is considered eco-friendly because it is highly recyclable. Recycling aluminum requires significantly less energy compared to producing new aluminum, making it a sustainable choice for packaging materials.

Why is food stored in aluminum containers?

Food is often stored in aluminum containers because aluminum provides an effective barrier against moisture, oxygen, and light, helping to preserve the freshness and quality of the food. Additionally, aluminum containers are lightweight, recyclable, and convenient for storage and transportation.