Home » Bags & Pouches » Spout Pouches » Aluminium Foil Spout Pouch

Aluminium Foil Spout Pouch

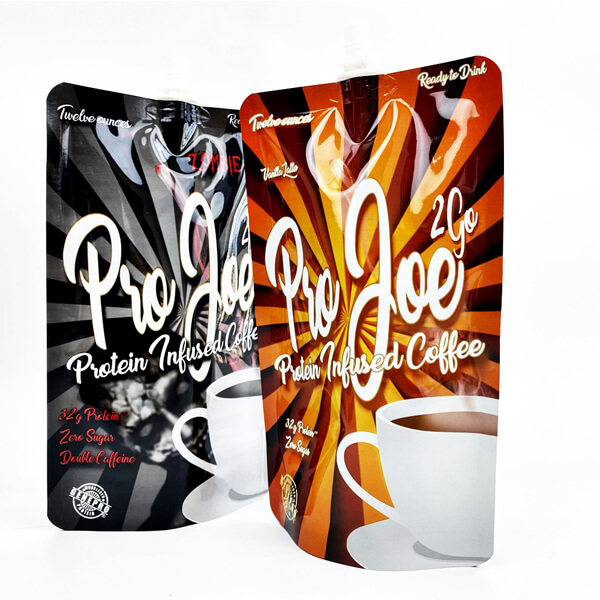

Designed as a flexible alternative to rigid containers, aluminium foil spout pouches (also known as fitment pouches) are increasingly popular with brand owners and retailers for packaging liquid, sticky and fine powder products.

Please note that we have a MOQ for our pouch. For pouches in stock, the MOQ is 500 pcs. For customized pouches, please see the MOQ as followed:

1, Digital Printing — 500 pcs

2, Gravure Printing — 5,000pcs

Rinpac assists you throughout your project: bag shape, material, thickness, capacity and printing options. Please contact us or mark your requirements on the inquiry quotation.

Order single or thousands of items at a time. Our warehouse and flexible shipping options are available for last-minute, deadline critical orders.

- Free Sample

*Customization is always available, please mark down your need in cart or just contact us.

Specification of Aluminium Foil Spout Pouch

| Features | We have the capability of producing spout pouches of custom shapes and specifications. |

| Advantages of the custom-shaped spout pouch | Standing out from the crowd with the unique shape: to differentiate the product from the competition by having a different look and feel than the general packaging |

| Artwork Enhancement: to enhance artwork with the matched shape of the packaging | |

| Disadvantages of the custom-shaped spout pouch | Tooling charges are required for the die-cut shape |

| Per customer’s design and requirements. | |

| Customizable Features | Shapes are customized to form your unique shape of the packaging. |

| Per customer’s design and requirements. | |

| Applicable to: 3 Side Seal Flat Pouch / Stand Up Pouch |

Request A Quote - Aluminium Foil Spout Pouch

Need something helped in a short time? We’ve got a plan for you.

Introduction to Aluminium Foil Spout Pouch

Aluminium foil spout pouches are a versatile and innovative packaging solution that combines the benefits of aluminum foil with the convenience of a spout. These pouches are widely used across various industries due to their exceptional barrier properties, durability, and user-friendly design. In this introduction, we’ll explore the features, advantages, and applications of aluminium foil spout pouches, highlighting their importance in modern packaging solutions.

Rinpac offers the best quality recyclable spout pouches at affordable prices.

Advantages of Aluminium Foil Spout Pouches

Aluminium foil spout pouches offer several advantages that make them a popular choice for packaging solutions:

Flexibility: Aluminium foil spout pouches are highly flexible, allowing for easy storage and transportation. They can be folded or rolled up when empty, saving space and reducing shipping costs. This flexibility makes them ideal for both retail and e-commerce packaging applications.

Barrier Protection: One of the key benefits of aluminium foil spout pouches is their excellent barrier protection. The aluminium foil layer acts as a barrier against moisture, oxygen, light, and other external factors that can degrade the quality of the packaged products. This helps to extend the shelf life of perishable goods and preserve their freshness and flavor.

Convenience: Aluminium foil spout pouches are designed for convenience and ease of use. The built-in spout allows for precise pouring and dispensing of liquids, sauces, and other products, minimizing mess and waste. Additionally, the pouches can be equipped with features such as resealable zippers or caps, allowing consumers to open and close the pouches multiple times without compromising product integrity.

Overall, the flexibility, barrier protection, and convenience offered by aluminium foil spout pouches make them an ideal packaging solution for a wide range of products, including food and beverages, pharmaceuticals, and personal care items.

Applications of Aluminium Foil Spout Pouches

Aluminium foil spout pouches find versatile applications across various industries due to their excellent barrier properties and convenience of use. Some common applications include:

Food Packaging: Aluminium foil spout pouches are widely used for packaging a variety of food products such as sauces, soups, condiments, and liquid snacks. The barrier properties of aluminium foil help to preserve the freshness and flavor of the contents, while the spout allows for easy pouring and dispensing, making them ideal for on-the-go consumption.

Beverage Packaging: These pouches are also popular for packaging beverages such as fruit juices, energy drinks, and dairy products. The aluminium foil layer provides protection against light, oxygen, and moisture, ensuring that the beverages retain their quality and taste for longer periods. The spout feature enables controlled pouring and prevents spillage, making them suitable for both single-serve and family-sized beverage packaging.

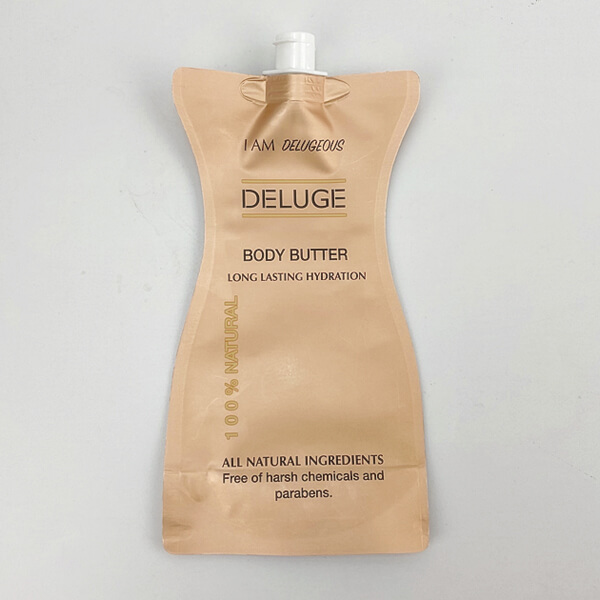

Cosmetic Packaging: Aluminium foil spout pouches are commonly used for packaging cosmetic and personal care products such as shampoo, shower gel, lotion, and liquid soap. The barrier properties of aluminium foil help to protect the contents from external contaminants and maintain their efficacy. The spout design allows for precise dispensing, minimizing product wastage and ensuring a clean and hygienic application.

Overall, aluminium foil spout pouches offer an effective and convenient packaging solution for a wide range of products in the food and beverage, cosmetic, and personal care industries.

Environmental Impact of Aluminium Foil Spout Pouches

The environmental impact of aluminium foil spout pouches is a topic of interest due to concerns about sustainability and waste management. While aluminium foil itself is recyclable, the recyclability of spout pouches depends on the entire packaging structure, including other materials such as plastics and laminates.

Recyclability: Aluminium foil is highly recyclable and can be recovered and reused in various applications. However, the recyclability of spout pouches may be affected by the presence of multiple materials in the packaging structure. Some recycling facilities may not have the technology to separate and process composite materials effectively, leading to challenges in recycling spout pouches. To address this issue, manufacturers are exploring innovative recycling technologies and collaborating with recycling facilities to improve the recyclability of spout pouches.

Reduced Material Usage: Aluminium foil spout pouches typically use less material compared to traditional rigid packaging formats such as cans and bottles. This reduction in material usage contributes to resource conservation and minimizes the environmental footprint of packaging. Additionally, the lightweight and flexible nature of spout pouches result in lower transportation emissions and energy consumption during production, further enhancing their environmental sustainability.

Overall, while aluminium foil spout pouches offer several environmental benefits such as reduced material usage and energy efficiency, their recyclability may vary depending on the specific composition of the packaging. Continued efforts to optimize packaging design, enhance recycling infrastructure, and promote consumer awareness are essential for maximizing the environmental sustainability of aluminium foil spout pouches.

Innovations in Aluminium Foil Spout Pouches

Innovations in aluminium foil spout pouches are driving advancements in packaging design and customization options, catering to diverse consumer preferences and industry requirements.

Enhanced Designs: Manufacturers are continually refining the design of aluminium foil spout pouches to improve functionality, aesthetics, and performance. Enhanced designs may include features such as reinforced seals for added durability, easy-grip spouts for convenient dispensing, and innovative closures for improved resealability. These design enhancements not only enhance the user experience but also contribute to the overall appeal and marketability of the product.

Customization Options: Customization is a key area of innovation in aluminium foil spout pouches, allowing brands to differentiate their products and connect with consumers on a deeper level. Manufacturers offer a wide range of customization options, including custom shapes and sizes, vibrant printing and branding capabilities, and special finishes such as matte or glossy textures. Additionally, advanced printing technologies enable the incorporation of intricate designs, vibrant colors, and eye-catching graphics to enhance shelf appeal and brand recognition.

By leveraging these innovations in design and customization, aluminium foil spout pouches offer brands the flexibility to create unique and impactful packaging solutions that resonate with their target audience. Whether it’s through enhanced functionality, eye-catching aesthetics, or sustainable features, aluminium foil spout pouches continue to evolve to meet the ever-changing demands of the modern consumer landscape.

How to Choose the Right Aluminium Foil Spout Pouch

Choosing the right aluminium foil spout pouch involves careful consideration of several factors to ensure that it meets your specific packaging needs and requirements.

Material Considerations: When selecting an aluminium foil spout pouch, it’s essential to evaluate the material composition to ensure it provides the necessary barrier properties and protection for your product. Aluminium foil offers excellent barrier protection against moisture, oxygen, light, and other external factors, preserving the freshness and quality of the contents. Additionally, consider factors such as puncture resistance, heat resistance, and compatibility with your product to ensure optimal performance and shelf life.

Size and Shape: Aluminium foil spout pouches come in a variety of sizes and shapes to accommodate different product volumes and packaging requirements. Assess your product’s volume and dimensions to determine the appropriate pouch size and shape that provides sufficient space for packaging while minimizing excess material. Consider whether a stand-up pouch design or a flat pouch design is more suitable for your product presentation and storage needs.

Closure Mechanisms: The closure mechanism of the aluminium foil spout pouch plays a crucial role in ensuring product freshness, preventing leaks, and facilitating convenient dispensing. Evaluate the different closure options available, such as screw caps, press-to-close zippers, and tamper-evident seals, to determine which one offers the best combination of security, functionality, and user-friendliness for your product. Consider factors such as ease of opening and resealing, tamper resistance, and compatibility with your product’s viscosity and flow characteristics.

By carefully considering these factors, you can choose the right aluminium foil spout pouch that meets your packaging requirements, enhances product protection, and delivers an excellent user experience for your customers.

Manufacturing Process of Aluminium Foil Spout Pouches

The manufacturing process of aluminium foil spout pouches involves several key steps to ensure the production of high-quality and functional packaging solutions.

Materials Selection: The process begins with the selection of suitable materials for the aluminium foil spout pouch. The primary materials include aluminium foil, which provides excellent barrier properties against moisture, oxygen, and light, ensuring the preservation of product freshness and quality. Additionally, other materials such as plastic films and laminates may be chosen to provide structural support, flexibility, and printing capabilities. These materials are selected based on factors such as product compatibility, desired barrier properties, and aesthetic requirements.

Printing: Once the materials are selected, the next step in the manufacturing process is printing. Printing is performed to apply graphics, branding elements, product information, and other visual designs onto the surface of the aluminium foil spout pouch. High-quality printing techniques such as flexography, gravure printing, or digital printing may be used to achieve vibrant colors, sharp images, and precise text placement. Printing is essential for enhancing shelf appeal, brand recognition, and consumer engagement.

Lamination: After printing, the printed materials are laminated together to create a multi-layered structure for the aluminium foil spout pouch. Lamination involves bonding the various layers of aluminium foil, plastic films, and other materials using heat and pressure to ensure they adhere firmly to each other. The lamination process enhances the pouch’s durability, strength, and barrier properties while also providing resistance to punctures, tears, and external contaminants. Additionally, lamination helps to seal the printed graphics and protect them from abrasion, fading, and moisture damage, ensuring the longevity of the packaging design.

By carefully executing each of these manufacturing steps, aluminium foil spout pouch manufacturers can produce high-quality, functional, and visually appealing packaging solutions that meet the diverse needs of their customers across various industries

Maintaining Quality and Shelf Life of Aluminium Foil Spout Pouches

Maintaining the quality and shelf life of aluminium foil spout pouches requires proper storage and handling practices to ensure optimal performance and product integrity.

Storage Recommendations:

- Store aluminium foil spout pouches in a clean, dry, and well-ventilated environment away from direct sunlight, heat sources, and moisture.

- Avoid storing pouches in areas with extreme temperatures or humidity levels, as this can compromise the integrity of the packaging materials and affect product freshness.

- Store pouches on pallets or shelves to prevent them from coming into contact with the ground or other surfaces that may harbor contaminants.

- Ensure proper airflow around the stored pouches to prevent the accumulation of condensation and mold growth.

Handling Instructions:

- Handle aluminium foil spout pouches with care to avoid damage to the packaging materials or spout components.

- When filling pouches with product, use equipment that is compatible with the pouch design and size to prevent overfilling or underfilling.

- Avoid sharp objects or rough handling that could puncture or tear the pouches, compromising their integrity and barrier properties.

- Seal the spouts securely after filling to prevent leakage and maintain product freshness during storage and transportation.

- Label filled pouches with appropriate product information, including batch numbers, expiry dates, and handling instructions, to ensure traceability and consumer safety.

By following these storage recommendations and handling instructions, manufacturers and suppliers can maintain the quality and shelf life of aluminium foil spout pouches, ensuring that they deliver superior performance and protection for packaged products throughout their lifecycle.

Cost Considerations of Aluminium Foil Spout Pouches

When considering the cost of aluminium foil spout pouches, it’s essential to conduct a comparative analysis to evaluate their long-term savings potential compared to other packaging options.

Comparative Analysis:

- Conduct a comprehensive cost comparison between aluminium foil spout pouches and alternative packaging formats, such as rigid containers, glass jars, or plastic bottles. Consider factors such as material costs, production expenses, transportation fees, and storage requirements.

- Evaluate the total cost of ownership for each packaging option, taking into account initial investment costs, ongoing operational expenses, and potential savings over the product lifecycle.

- Assess the environmental impact of each packaging solution, including factors such as recyclability, material waste, and carbon footprint, to determine the overall sustainability and cost-effectiveness of aluminium foil spout pouches.

Long-term Savings:

- Aluminium foil spout pouches offer significant long-term savings potential due to their lightweight construction, which reduces shipping and transportation costs compared to heavier packaging formats.

- The flexible design of spout pouches allows for efficient use of packaging materials, minimizing material waste and maximizing storage space utilization, resulting in potential cost savings for manufacturers and retailers.

- Additionally, the barrier properties of aluminium foil provide excellent protection against oxygen, moisture, and light, extending the shelf life of packaged products and reducing the risk of spoilage or product loss, which can result in significant cost savings over time.

By conducting a thorough comparative analysis and considering the long-term savings potential of aluminium foil spout pouches, businesses can make informed decisions about their packaging choices, ensuring cost-effectiveness and sustainability while maintaining product quality and integrity.

Future Trends in Aluminium Foil Spout Pouches

As the packaging industry continues to evolve, several future trends are emerging in the realm of aluminium foil spout pouches, focusing on sustainable packaging solutions and technological advancements.

Sustainable Packaging Solutions:

- Future trends in aluminium foil spout pouches are increasingly influenced by the growing demand for sustainable packaging solutions. Manufacturers are exploring innovative ways to reduce environmental impact by incorporating eco-friendly materials and adopting sustainable production practices.

- There is a shift towards the use of renewable and biodegradable materials in the manufacturing of aluminium foil spout pouches, such as bio-based plastics and compostable films, to minimize the use of non-renewable resources and reduce waste generation.

- Additionally, the implementation of closed-loop recycling systems and circular economy models is becoming more prevalent, enabling the recovery and reuse of materials to create new packaging products, thereby promoting resource efficiency and waste reduction.

Technological Advancements:

- Technological advancements play a crucial role in shaping the future of aluminium foil spout pouches, driving innovation and enhancing product performance. Manufacturers are investing in research and development efforts to develop advanced packaging solutions that offer improved functionality, convenience, and sustainability.

- Future aluminium foil spout pouches may feature enhanced barrier properties, extending product shelf life and preserving freshness for longer periods. This can be achieved through the incorporation of nanotechnology or advanced coating technologies that provide superior protection against oxygen, moisture, and light.

- Furthermore, technological innovations in printing and manufacturing processes enable greater customization and personalization of aluminium foil spout pouches, allowing brands to create unique packaging designs and engage consumers more effectively.

By embracing sustainable packaging solutions and leveraging technological advancements, the future of aluminium foil spout pouches is poised to deliver enhanced functionality, environmental benefits, and brand differentiation in the marketplace.

Conclusion

In conclusion, aluminium foil spout pouches offer a versatile and sustainable packaging solution for a wide range of products across various industries. With their numerous advantages, including flexibility, barrier protection, and convenience, these pouches continue to gain popularity among manufacturers and consumers alike. As the demand for eco-friendly packaging grows, the industry is witnessing a shift towards the use of renewable materials and closed-loop recycling systems, driving innovation and promoting environmental stewardship.

Looking ahead, future trends in aluminium foil spout pouches are expected to focus on sustainable packaging solutions and technological advancements, offering enhanced functionality, performance, and brand differentiation. By embracing these trends, manufacturers can meet the evolving needs of consumers while contributing to a more sustainable and environmentally conscious packaging ecosystem.

Get top quality bags and pouches from Rinpac. Get quote now.

FAQs

What are the disadvantages of spout pouches?

Spout pouches offer several advantages such as convenience, portability, and eco-friendliness, but they also come with some disadvantages. These include:

- Barrier Properties: Spout pouches may not offer the same level of barrier protection as rigid packaging options like cans or glass bottles, which could affect the shelf life of certain products.

- Puncture Risk: Compared to rigid packaging, spout pouches are more susceptible to punctures or tears, which can lead to product spoilage or leakage.

- Limited Size Range: Spout pouches may not be suitable for packaging larger volumes of products due to their flexible nature, limiting their application in certain industries.

- Manufacturing Complexity: The production process for spout pouches involves multiple layers and components, which can increase manufacturing complexity and potentially lead to higher production costs.

What is a spout pouch used for?

Spout pouches are versatile packaging solutions used for various products across different industries. Some common uses include:

- Liquid Products: Spout pouches are ideal for packaging liquids such as beverages, sauces, soups, and oils due to their ability to prevent leakage and maintain product freshness.

- Semi-Liquid Products: They are also suitable for packaging semi-liquid products like baby food, yogurt, condiments, and purees, offering convenient dispensing and portion control.

- Dry Products: Certain dry products like snacks, pet food, powdered supplements, and grains can also be packaged in spout pouches with appropriate modifications to the packaging design.

What is the use of Aluminium foil pouch?

Aluminium foil pouches are widely used for packaging various products due to their excellent barrier properties and versatility. Some common uses of aluminium foil pouches include:

- Food Packaging: Aluminium foil pouches are commonly used for packaging perishable food items such as snacks, dried fruits, chocolates, and ready-to-eat meals, providing protection against moisture, oxygen, and light.

- Pharmaceutical Packaging: They are also used in the pharmaceutical industry for packaging medications, tablets, capsules, and other sensitive healthcare products, ensuring product integrity and shelf life.

- Industrial Applications: Aluminium foil pouches find applications in various industrial sectors for packaging chemicals, electronic components, and other sensitive materials that require protection from environmental factors.

How do you fill a spout pouch?

Filling a spout pouch typically involves the following steps:

- Preparation: Ensure that the spout pouch is clean and free from any contaminants before filling.

- Positioning: Place the spout pouch in a filling machine or station designed specifically for spout pouch filling.

- Filling: Use an appropriate filling mechanism, such as a nozzle or pump, to dispense the product into the spout pouch. The filling process should be controlled to prevent overfilling or underfilling.

- Sealing: Once the pouch is filled with the desired amount of product, seal the spout using heat sealing or other suitable sealing methods to ensure the product remains intact and secure during storage and transportation.

- Quality Check: Conduct quality checks to verify that the spout pouches are properly filled and sealed before they are packaged for distribution.