Home » Bags & Pouches » Stand Up Pouches » Stand Up Barrier Pouches

Stand Up Barrier Pouches

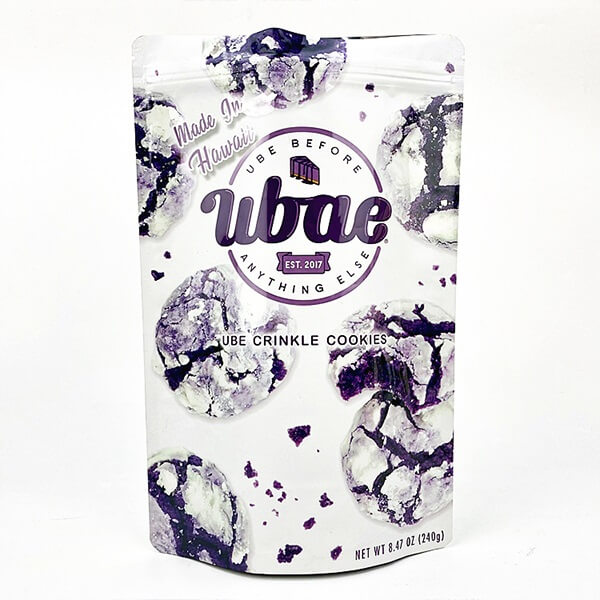

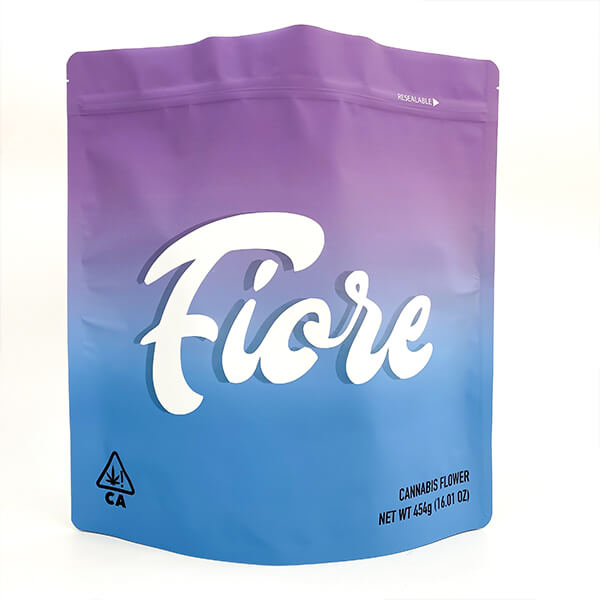

Stand up barrier pouches are the ideal container for a variety of solid, liquid and powdered foods as well as non-food items. They are suitable for growing brands and large brands interested in packaging supply chain management.

Please note that we have a MOQ for our pouch. For pouches in stock, the MOQ is 500 pcs. For customized pouches, please see the MOQ as followed:

1, Digital Printing — 500 pcs

2, Gravure Printing — 5,000pcs

Rinpac assists you throughout your project: bag shape, material, thickness, capacity and printing options. Please contact us or mark your requirements on the inquiry quotation.

Order single or thousands of items at a time. Our warehouse and flexible shipping options are available for last-minute, deadline critical orders.

- Free Sample

*Customization is always available, please mark down your need in cart or just contact us.

Specification

| Materials | Per customer’s packaging needs. Using materials such as clear poly, metalized films, foil laminations and kraft paper. All pouches are made of food grade solvent free packaging materials. |

| Sizes | Per customer’s packaging needs |

| Bottom Gusset Seals | K-Seals: Angled bottom corner seals |

| Doyen Seals: Rounded bottom seals | |

| Re-sealable Features | Press-to-close zippers: Economical and commonly used |

| Sliders: Convenient and easy to open | |

| Additional Features | Spouts or fitments |

| Degassing Valves | |

| Tear notches | |

| Rounded Corners | |

| Hang holes or handles | |

| Laser scoring or laser perforation | |

| Knocked out windows providing a sneak peek of what’s inside: clear window, frosted window, or matte finish with glossy clear window | |

| Die-cut shapes | |

| Printing | Glossy printing |

| Matte finish printing | |

| Glossy printing with spot matte finishes | |

| Per customer’s design and requirements. |

Video

Request A Quote

Need something helped in a short time? We’ve got a plan for you.

Wholesale Stand-Up Barrier Pouches From Rinpac In China

Wholesale stand-up barrier pouches have emerged as a popular choice in the packaging industry for their ability to provide superior protection and extended shelf life for a variety of products. This article explores the benefits of wholesale stand-up barrier pouches and highlights Rinpac, a leading manufacturer in China known for its expertise in barrier packaging solutions.

Advantages of Wholesale Stand-Up Barrier Pouches

Enhanced Product Protection

One of the primary advantages of wholesale stand-up barrier pouches is their ability to offer enhanced protection for packaged goods. These pouches are designed using high-quality barrier materials that provide an effective barrier against moisture, oxygen, light, and other external factors that can compromise product quality and freshness. By creating a protective barrier, stand-up barrier pouches help preserve the integrity and flavor of the contents, ensuring a superior product experience for consumers.

Extended Shelf Life

In addition to enhanced product protection, wholesale stand-up barrier pouches also contribute to the extended shelf life of packaged goods. The barrier properties of these pouches help prevent oxidation, microbial growth, and other forms of deterioration, allowing products to remain fresher for longer periods. This extended shelf life not only reduces the risk of product spoilage and waste but also enhances the overall value proposition for consumers, making stand-up barrier pouches a preferred choice for businesses seeking to maximize product longevity.

Eco-Friendliness

Furthermore, wholesale stand-up barrier pouches are an eco-friendly packaging solution compared to traditional packaging formats such as plastic bottles or rigid containers. Many stand-up barrier pouches are made from lightweight and recyclable materials, reducing the environmental impact of packaging waste. Additionally, their compact size and efficient use of materials result in lower transportation costs and carbon emissions, contributing to a more sustainable supply chain.

Rinpac: A Leading Manufacturer of Wholesale Stand-Up Barrier Pouches

Company Overview

Rinpac is a reputable manufacturer based in China, specializing in the production of high-quality wholesale stand-up barrier pouches. With years of experience and a commitment to innovation, Rinpac has earned a reputation for delivering superior barrier packaging solutions tailored to meet the unique needs of its clients worldwide.

Specialization in Barrier Packaging

One of Rinpac’s key areas of expertise is barrier packaging, including stand-up barrier pouches designed to provide maximum protection for a variety of products. Rinpac utilizes advanced manufacturing processes and cutting-edge barrier materials to create pouches that meet the most stringent quality and performance standards, ensuring optimal product freshness and integrity.

Features of Rinpac’s Wholesale Stand-Up Barrier Pouches

High-Quality Barrier Materials

Rinpac’s wholesale stand-up barrier pouches are crafted from premium barrier materials known for their exceptional strength, durability, and barrier properties. These materials are carefully selected to provide the specific barrier properties required for each application, whether it’s moisture resistance for food packaging or UV protection for pharmaceuticals. With Rinpac’s stand-up barrier pouches, businesses can trust that their products are well-protected against external factors that can compromise quality and safety.

Customization Options

Moreover, Rinpac offers extensive customization options to help businesses create unique and impactful packaging solutions. From custom prints and colors to special finishes and features, Rinpac collaborates closely with clients to bring their branding vision to life and create packaging that resonates with their target audience. Whether it’s a bold design statement or subtle branding elements, Rinpac’s customization capabilities allow businesses to differentiate their products and stand out in competitive markets.

Ordering Process and Customer Support

Streamlined Ordering Experience

Rinpac is committed to providing a streamlined ordering experience for its clients. The company’s user-friendly online platform allows for easy customization and ordering of wholesale stand-up barrier pouches, while its dedicated sales team ensures prompt communication and transparent updates throughout the process. With Rinpac, businesses can expect a hassle-free ordering experience from start to finish.

Responsive Customer Service

Additionally, Rinpac offers responsive customer service to address any questions or concerns that may arise. Whether it’s technical support, product inquiries, or logistics assistance, Rinpac’s knowledgeable team is available to provide personalized assistance and guidance, ensuring that clients have the support they need every step of the way.

Testimonials from Satisfied Clients

Positive Experiences with Rinpac

Numerous testimonials from satisfied clients attest to the quality and reliability of Rinpac’s products and services. From small businesses to multinational corporations, clients praise Rinpac for its attention to detail, timely delivery, and exceptional customer support, highlighting the company’s commitment to exceeding expectations.

Comparison with Traditional Packaging

Advantages Over Other Packaging Formats

Compared to traditional packaging formats such as bottles, jars, and cans, wholesale stand-up barrier pouches offer several distinct advantages. Their lightweight construction reduces shipping costs and environmental impact, while their barrier properties help preserve product freshness and extend shelf life. Additionally, stand-up barrier pouches offer greater flexibility in terms of design and customization, allowing businesses to create packaging that reflects their brand identity and resonates with consumers.

Market Trends and Future Prospects

Growing Demand for Barrier Packaging

As consumer awareness of food safety and product quality continues to grow, there is a rising demand for barrier packaging solutions like wholesale stand-up barrier pouches. With their ability to provide superior protection and extended shelf life, barrier pouches are poised to remain a preferred choice for businesses across various industries, driving innovation and meeting the evolving needs of consumers worldwide.

Conclusion

In conclusion, wholesale stand-up barrier pouches offer numerous benefits for businesses seeking to enhance product protection, extend shelf life, and reduce environmental impact. With their advanced barrier properties, customization options, and responsive customer support, Rinpac’s stand-up barrier pouches are an ideal packaging solution for businesses looking to maximize the freshness and appeal of their products. By partnering with Rinpac, businesses can access high-quality barrier pouches tailored to their specific needs, backed by industry-leading expertise and support.