Home » Bags & Pouches » Stand Up Pouches » Compostable Stand Up Pouches

Compostable Stand Up Pouches

Compostable stand up pouches are the ideal container for a variety of solid, liquid and powdered foods as well as non-food items. They are suitable for growing brands and large brands interested in packaging supply chain management.

Please note that we have a MOQ for our pouch. For pouches in stock, the MOQ is 500 pcs. For customized pouches, please see the MOQ as followed:

1, Digital Printing — 500 pcs

2, Gravure Printing — 5,000pcs

Rinpac assists you throughout your project: bag shape, material, thickness, capacity and printing options. Please contact us or mark your requirements on the inquiry quotation.

Order single or thousands of items at a time. Our warehouse and flexible shipping options are available for last-minute, deadline critical orders.

- Free Sample

*Customization is always available, please mark down your need in cart or just contact us.

Specification

| Materials | Per customer’s packaging needs. Using materials such as clear poly, metalized films, foil laminations and kraft paper. All pouches are made of food grade solvent free packaging materials. |

| Sizes | Per customer’s packaging needs |

| Bottom Gusset Seals | K-Seals: Angled bottom corner seals |

| Doyen Seals: Rounded bottom seals | |

| Re-sealable Features | Press-to-close zippers: Economical and commonly used |

| Sliders: Convenient and easy to open | |

| Additional Features | Spouts or fitments |

| Degassing Valves | |

| Tear notches | |

| Rounded Corners | |

| Hang holes or handles | |

| Laser scoring or laser perforation | |

| Knocked out windows providing a sneak peek of what’s inside: clear window, frosted window, or matte finish with glossy clear window | |

| Die-cut shapes | |

| Printing | Glossy printing |

| Matte finish printing | |

| Glossy printing with spot matte finishes | |

| Per customer’s design and requirements. |

Video

Request A Quote

Need something helped in a short time? We’ve got a plan for you.

Wholesale Compostable Stand Up Pouches From Rinpac In China

In today’s eco-conscious world, businesses are increasingly seeking sustainable packaging solutions to minimize their environmental footprint. One such innovative solution is wholesale compostable stand-up pouches, which offer both functionality and eco-friendliness. Rinpac, based in China, stands out as a leading manufacturer of these environmentally responsible packaging options.

1. Introduction to Wholesale Compostable Stand Up Pouches

Stand-up pouches have gained popularity in various industries due to their convenience, versatility, and ability to provide extended shelf life to products. When these qualities are combined with compostable materials, it creates a packaging solution that aligns with the growing demand for sustainability.

2. The Environmental Impact of Packaging

Importance of Sustainable Packaging

Traditional packaging materials, such as plastic and aluminum, contribute significantly to environmental pollution and resource depletion. Sustainable packaging aims to reduce this impact by using renewable resources and minimizing waste generation throughout the product lifecycle.

Rise of Compostable Packaging Solutions

Compostable packaging has emerged as a viable alternative to traditional materials, offering the advantage of biodegradability without compromising on performance. As consumers become more environmentally conscious, the demand for compostable packaging solutions continues to rise.

3. Rinpac: A Leader in Compostable Packaging

Company Overview

Rinpac is a renowned manufacturer of eco-friendly packaging solutions, specializing in compostable stand-up pouches. With state-of-the-art facilities and a dedicated team, Rinpac is committed to delivering high-quality, sustainable packaging options to its global clientele.

Commitment to Sustainability

Rinpac prioritizes sustainability in every aspect of its operations, from sourcing raw materials to manufacturing processes and product distribution. By adhering to strict environmental standards, Rinpac ensures that its packaging solutions meet the highest sustainability criteria.

4. Advantages of Wholesale Compostable Stand Up Pouches

Durability and Strength

Despite being compostable, stand-up pouches from Rinpac are designed to withstand the rigors of transportation and storage, ensuring that products remain protected throughout the supply chain.

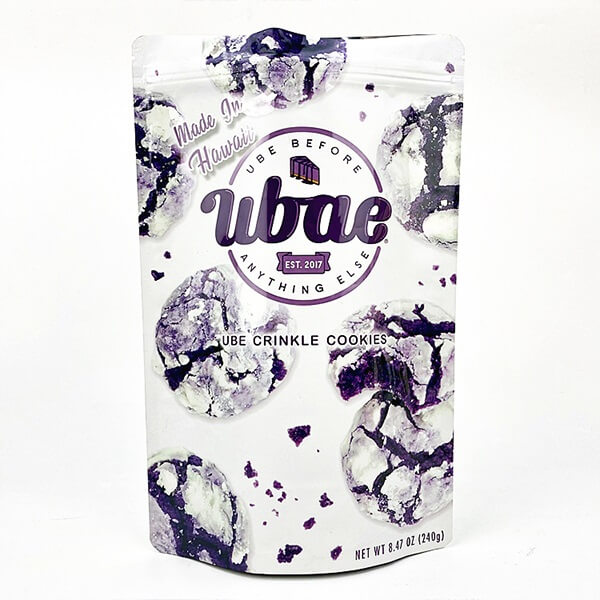

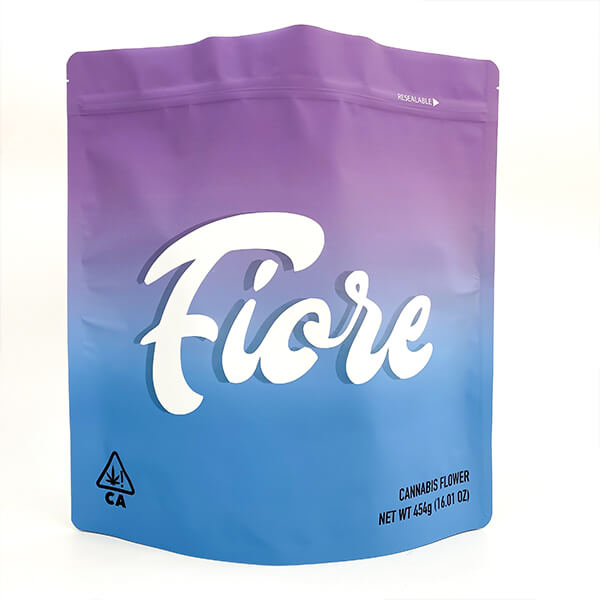

Customization Options

Rinpac offers a wide range of customization options, allowing businesses to tailor their packaging to reflect their brand identity and messaging effectively.

Biodegradability and Eco-friendliness

One of the primary advantages of compostable stand-up pouches is their ability to break down into natural components under composting conditions, minimizing environmental impact and reducing landfill waste.

5. Applications of Stand Up Pouches

Stand-up pouches find applications across various industries, including:

- Food Packaging: Ideal for snacks, coffee, dry fruits, and spices.

- Pet Food Packaging: Ensures freshness and convenience for pet owners.

- Personal Care Products: Suitable for shampoo, lotions, and cosmetics.

6. Quality Assurance and Certifications

Standards for Compostable Packaging

Rinpac’s compostable stand-up pouches adhere to international standards for compostability, ensuring that they meet strict criteria for biodegradability and environmental safety.

Certifications Ensuring Product Integrity

Rinpac holds certifications from recognized organizations, verifying the authenticity and sustainability of its packaging solutions, providing customers with confidence in their choice of eco-friendly packaging.

7. Manufacturing Process of Compostable Stand Up Pouches

Materials Used

Rinpac utilizes renewable and biodegradable materials, such as plant-based PLA (Polylactic Acid) and compostable films, in the manufacturing of its stand-up pouches.

Production Techniques

Advanced manufacturing techniques ensure that Rinpac’s compostable stand-up pouches meet stringent quality standards while minimizing waste and energy consumption.

8. Cost Considerations and Economic Benefits

Initial Investment vs. Long-Term Savings

While the initial cost of compostable packaging may be slightly higher than traditional options, businesses can realize long-term savings through reduced environmental impact, potential marketing advantages, and enhanced brand reputation.

Market Demand and Consumer Perception

As consumer awareness regarding environmental issues grows, the market demand for sustainable packaging solutions, such as compostable stand-up pouches, continues to increase, presenting businesses with an opportunity to differentiate themselves and attract environmentally conscious consumers.

9. Challenges and Solutions

Barrier to Adoption

One of the primary challenges in adopting compostable packaging is the perceived cost and logistical challenges associated with transitioning from traditional materials. However, with the right guidance and support from suppliers like Rinpac, businesses can overcome these barriers effectively.

Overcoming Resistance and Educating Consumers

Educating consumers about the benefits of compostable packaging and dispelling myths regarding its performance and cost can help overcome resistance and drive greater acceptance of sustainable packaging solutions.

10. Future Trends in Sustainable Packaging

Technological Innovations

Advancements in material science and packaging technology are expected to further improve the performance and cost-effectiveness of compostable packaging solutions, driving their widespread adoption across industries.

Market Projections

The market for compostable packaging is projected to experience significant growth in the coming years as more businesses and consumers prioritize sustainability, presenting opportunities for innovation and market expansion.

Conclusion

Wholesale compostable stand-up pouches from Rinpac offer a sustainable packaging solution that combines functionality, durability, and eco-friendliness. By choosing compostable packaging, businesses can demonstrate their commitment to environmental stewardship while meeting consumer demand for sustainable products.

FAQs

Are compostable stand-up pouches as durable as traditional packaging?

Compostable stand-up pouches from Rinpac are designed to offer durability and strength comparable to traditional packaging options while being environmentally friendly.

What certifications do Rinpac’s compostable pouches hold?

Rinpac’s compostable pouches hold certifications from recognized organizations, ensuring compliance with international standards for compostability.

Can compostable stand-up pouches be customized for branding purposes?

Yes, Rinpac offers customization options for its compostable stand-up pouches, allowing businesses to showcase their branding and messaging effectively.

How do compostable stand-up pouches contribute to sustainability?

Compostable stand-up pouches break down into natural components under composting conditions, reducing environmental impact and landfill waste.

What industries can benefit from using compostable stand-up pouches?

Various industries, including food, pet food, and personal care, can benefit from using compostable stand-up pouches due to their versatility and eco-friendliness.