Home » Bags & Pouches » Shaped Pouches » Shaped Pouch For Snacks

Shaped Pouch For Snacks

Shaped pouch for sancks offers a guarantee to stand out on the retail shelf.

Please note that we have a MOQ for our pouch. For pouches in stock, the MOQ is 500 pcs. For customized pouches, please see the MOQ as followed:

1, Digital Printing — 500 pcs

2, Gravure Printing — 5,000pcs

Rinpac assists you throughout your project: bag shape, material, thickness, capacity and printing options. Please contact us or mark your requirements on the inquiry quotation.

Order single or thousands of items at a time. Our warehouse and flexible shipping options are available for last-minute, deadline critical orders.

- Free Sample

*Customization is always available, please mark down your need in cart or just contact us.

Specification

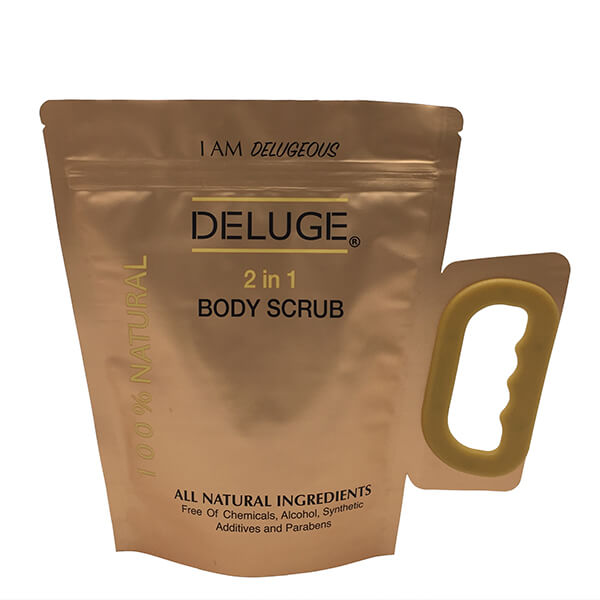

| Size | Custom sizes.It depends on your requirement. |

| Structures/Materials | Custom materials.PET / FOIL / POLY, PET / POLY, PET / MET PET / POLY,etc. |

| Thickness | 50Mircons-200Mircons (2Mil-8Mil) |

| Function | Punch Hole, Handle, Ziplock, Spout |

| Printing | Glossy Vanishing, Matte Finishing, Soft Touch, Hot Stamping |

| Optional Features | Degassing Valve / Ziplock / Foil Tie / Clear Window |

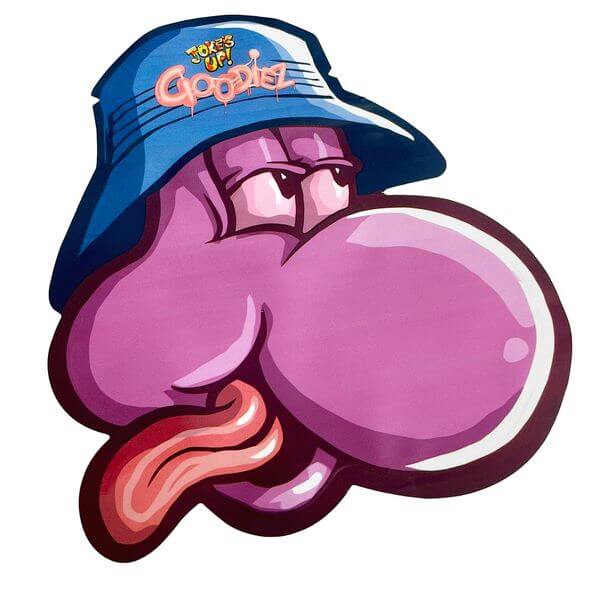

| Technical | Apouch which is irregular in shape.Designed to stand out from the competition.Can be designed to customer shape requirement(\”within specification).Can use special finishes to enhance the design,with options of adding zippers and hang-sell features. |

| Application | Confectionery -(Candy,Chocolates,Fruit Chews)Liquid-(Fruit Juice,Sauces,Energy Drink) Novelty,Seasonal items |

Video

Request A Quote

Need something helped in a short time? We’ve got a plan for you.

Wholesale Shaped Pouch For Snacks From Rinpac In China

In today’s competitive snack industry, packaging plays a crucial role in attracting consumers and ensuring product freshness. Shaped pouches have emerged as a popular packaging solution, offering both functionality and aesthetic appeal. Rinpac, a leading wholesale supplier based in China, specializes in manufacturing high-quality shaped pouches tailored to the unique needs of snack brands worldwide.

Introduction to Shaped Pouches

Shaped pouches, also known as stand-up pouches, are innovative packaging solutions designed to enhance product visibility and convenience. Unlike traditional packaging formats, shaped pouches offer a three-dimensional presentation, making them ideal for displaying snacks prominently on retail shelves.

Importance of Packaging in the Snack Industry

In the snack industry, packaging serves as a powerful marketing tool, influencing consumer purchasing decisions. Eye-catching designs and practical features, such as resealable zippers and tear notches, contribute to the overall consumer experience and brand perception.

Rinpac: A Leading Wholesale Supplier in China

Rinpac has established itself as a trusted supplier of wholesale shaped pouches, catering to the diverse needs of snack manufacturers worldwide. With state-of-the-art manufacturing facilities and a commitment to quality, Rinpac delivers innovative packaging solutions that meet the highest industry standards.

Quality Assurance

Rinpac employs stringent quality control measures throughout the production process to ensure consistency and reliability. From raw material selection to final inspection, every step is carefully monitored to uphold the brand’s reputation for excellence.

Customization Options

One of the key advantages of partnering with Rinpac is its extensive customization capabilities. Whether brands require custom shapes, sizes, or printing designs, Rinpac’s team of experienced professionals works closely with clients to bring their vision to life.

Advantages of Wholesale Shaped Pouches from Rinpac

Cost-effectiveness

By opting for wholesale shaped pouches from Rinpac, snack brands can benefit from cost savings without compromising on quality. Bulk ordering allows for economies of scale, making it a cost-effective solution for businesses of all sizes.

Branding Opportunities

Shaped pouches offer ample space for branding and product messaging, enabling brands to stand out in crowded retail environments. With vibrant graphics and eye-catching designs, Rinpac helps brands create memorable packaging experiences that resonate with consumers.

Convenience and Shelf Appeal

The convenience of shaped pouches, coupled with their shelf appeal, makes them a popular choice among snack manufacturers. Easy-to-open features and resealable closures enhance the consumer experience, encouraging repeat purchases and brand loyalty.

Types of Snacks Suitable for Shaped Pouch Packaging

Shaped pouches are versatile packaging solutions suitable for a wide range of snacks, including:

- Granola bars

- Dried fruits

- Nuts and seeds

- Trail mixes

- Potato chips

- Popcorn

Sustainability Initiatives by Rinpac

In response to growing environmental concerns, Rinpac is committed to sustainability and eco-friendly practices. The company invests in recyclable materials and renewable energy sources, minimizing its carbon footprint and contributing to a greener future.

How to Order Wholesale Shaped Pouches from Rinpac

Customization Process

To order wholesale shaped pouches from Rinpac, brands can start by discussing their requirements with the company’s sales team. From there, Rinpac provides personalized recommendations and design assistance to ensure that the final product meets expectations.

Minimum Order Quantities

Rinpac offers flexible ordering options to accommodate the needs of different businesses. While minimum order quantities apply, the company strives to provide competitive pricing and value-added services to its clients.

Shipping and Delivery

Once the order is confirmed, Rinpac manages the shipping and delivery process efficiently, ensuring timely arrival of the products. With a global logistics network, the company can fulfill orders promptly and reliably.

Future Trends in Shaped Pouch Packaging

Looking ahead, shaped pouch packaging is expected to continue evolving to meet changing consumer preferences and industry trends. Innovations in materials, printing technologies, and sustainability initiatives will drive further advancements in packaging design and functionality.

Conclusion

In conclusion, wholesale shaped pouches from Rinpac offer snack brands a compelling packaging solution that combines aesthetics, functionality, and sustainability. With customizable options, cost-effective pricing, and a commitment to quality, Rinpac is the partner of choice for businesses looking to elevate their brand presence in the competitive snack market.

FAQs

Can Rinpac accommodate unique shapes and sizes for shaped pouches?

Yes, Rinpac specializes in custom packaging solutions and can accommodate unique shapes and sizes based on client specifications.

Are Rinpac’s shaped pouches suitable for both dry and liquid snacks?

Absolutely, Rinpac’s shaped pouches are versatile and can be tailored to accommodate a variety of snack types, including both dry and liquid products.

What printing options are available for branded packaging with Rinpac?

Rinpac offers a range of printing options, including flexographic and digital printing, to ensure vibrant and high-quality branding on shaped pouches.

Does Rinpac offer sustainable packaging solutions?

Yes, sustainability is a top priority for Rinpac, and the company offers eco-friendly packaging options made from recyclable materials.

How can I request a quote for wholesale shaped pouches from Rinpac?

To request a quote or discuss your packaging needs with Rinpac’s team, simply visit their website or contact their sales department directly.