Home » Bags & Pouches » Shaped Pouches » Customized Shaped Pouch

Customized Shaped Pouch

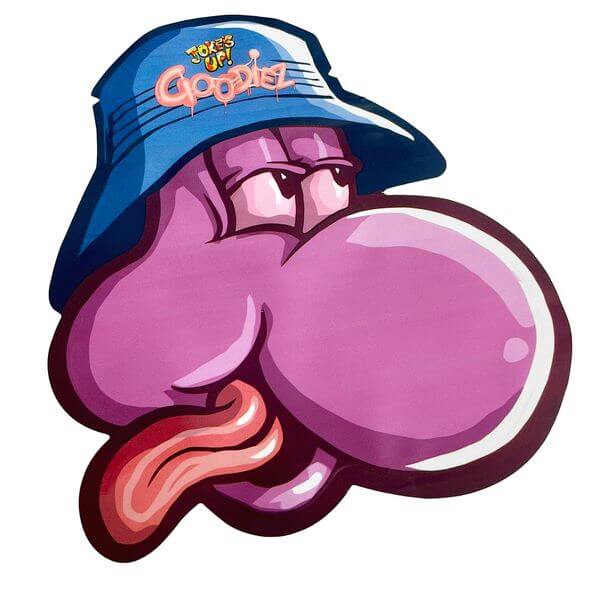

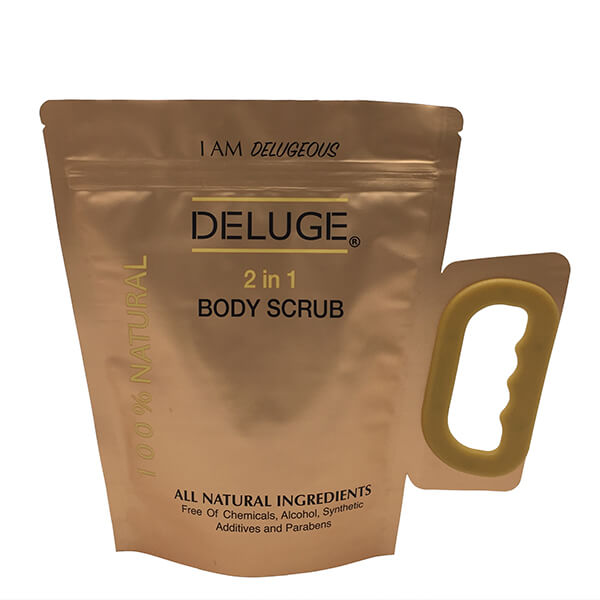

Customized shaped pouches are mainly for promotion products offer a guarantee to stand out on the retail shelf.

Please note that we have a MOQ for our pouch. For pouches in stock, the MOQ is 500 pcs. For customized pouches, please see the MOQ as followed:

1, Digital Printing — 500 pcs

2, Gravure Printing — 5,000pcs

Rinpac assists you throughout your project: bag shape, material, thickness, capacity and printing options. Please contact us or mark your requirements on the inquiry quotation.

Order single or thousands of items at a time. Our warehouse and flexible shipping options are available for last-minute, deadline critical orders.

- Free Sample

*Customization is always available, please mark down your need in cart or just contact us.

Specification

| Size | Custom sizes.It depends on your requirement. |

| Structures/Materials | Custom materials.PET / FOIL / POLY, PET / POLY, PET / MET PET / POLY,etc. |

| Thickness | 50Mircons-200Mircons (2Mil-8Mil) |

| Function | Punch Hole, Handle, Ziplock, Spout |

| Printing | Glossy Vanishing, Matte Finishing, Soft Touch, Hot Stamping |

| Optional Features | Degassing Valve / Ziplock / Foil Tie / Clear Window |

| Technical | Apouch which is irregular in shape.Designed to stand out from the competition.Can be designed to customer shape requirement(\”within specification).Can use special finishes to enhance the design,with options of adding zippers and hang-sell features. |

| Application | Confectionery -(Candy,Chocolates,Fruit Chews)Liquid-(Fruit Juice,Sauces,Energy Drink) Novelty,Seasonal items |

Video

Request A Quote

Need something helped in a short time? We’ve got a plan for you.

Customized Shaped Pouch From China – Rinpac

In today’s dynamic market, packaging plays a pivotal role in product presentation and consumer engagement. One innovative solution gaining prominence is the customized shaped pouch, and when it comes to excellence in this niche, Rinpac from China stands out as a leading manufacturer.

Advantages of Customized Shaped Pouches

Customized shaped pouches offer a myriad of advantages for businesses seeking unique and eye-catching packaging solutions. The flexibility in design allows companies to break free from traditional packaging constraints. Whether it’s a distinctive shape or a creative design element, these pouches provide unparalleled opportunities for branding.

Rinpac, with its expertise in crafting innovative designs, takes customization to the next level. The practicality and convenience of shaped pouches make them an ideal choice for various industries, providing both aesthetic appeal and functionality.

Rinpac’s Expertise in Customized Shaped Pouches

Rinpac boasts a rich background in the manufacturing of customized shaped pouches. With a team of skilled professionals, the company specializes in bringing unique and cutting-edge designs to life. Their commitment to quality assurance is reflected in the certifications they hold, ensuring that customers receive products of the highest standards.

Materials Used in Rinpac’s Shaped Pouches

Environmental consciousness is a key consideration for modern businesses. Rinpac addresses this concern by offering eco-friendly options without compromising on durability and safety. The materials used are carefully chosen to align with sustainability goals, making Rinpac a responsible choice for businesses committed to green practices.

Customization Process

Rinpac understands the importance of customer involvement in the design process. The company works closely with clients to create tailored solutions that align with their brand identity. This collaborative approach ensures that each pouch is a unique representation of the client’s vision, making it a powerful tool for brand differentiation.

Applications Across Industries

The versatility of customized shaped pouches extends across various industries. From the food and beverage sector to cosmetics, pharmaceuticals, and even pet care, Rinpac’s pouches find applications in diverse markets. The adaptability of these pouches makes them a versatile choice for packaging solutions.

Quality Control Measures at Rinpac

Rinpac prioritizes quality control through rigorous testing procedures. The company adheres to international standards, ensuring that every pouch meets the highest benchmarks of quality and safety. This commitment to excellence has contributed to Rinpac’s reputation as a reliable and trustworthy manufacturer.

Environmental Sustainability Initiatives

In an era where environmental concerns are paramount, Rinpac takes proactive steps toward sustainability. The company’s commitment to eco-friendly practices is reflected in its choice of materials and production processes. Businesses can align themselves with Rinpac’s eco-conscious approach by choosing their customized shaped pouches.

Global Reach and Distribution

Rinpac’s global distribution network ensures that their innovative pouches reach businesses worldwide. Testimonials from satisfied clients underscore the company’s reliability and efficiency in delivering high-quality products. The global reach of Rinpac positions it as a preferred partner for businesses seeking packaging solutions that make a lasting impact.

Cost-Effectiveness of Customized Shaped Pouches

While customization often implies higher costs, Rinpac offers competitive pricing for its shaped pouches. A comparative analysis reveals that the long-term benefits, such as increased brand recognition and consumer loyalty, far outweigh the initial investment. Businesses can enjoy both aesthetic appeal and cost-effectiveness with Rinpac’s customized solutions.

Future Trends in Shaped Pouch Manufacturing

As technology evolves and consumer preferences change, the future of shaped pouch manufacturing holds exciting possibilities. Rinpac remains at the forefront of innovation, continuously adapting to emerging trends. The company’s commitment to staying ahead of the curve ensures that businesses partnering with Rinpac receive packaging solutions that meet future demands.

Common Misconceptions About Customized Shaped Pouches

Despite their growing popularity, some misconceptions surround customized shaped pouches. Addressing these myths is crucial to helping businesses make informed decisions. Rinpac provides clarifications to dispel any doubts, ensuring that potential clients have accurate information about the benefits and practicality of shaped pouches.

Customer Satisfaction and Feedback

Positive reviews and testimonials from Rinpac’s clients highlight the level of customer satisfaction the company strives to achieve. Addressing any concerns or criticisms transparently, Rinpac maintains open communication with its clients, fostering trust and long-lasting partnerships. The positive experiences of other businesses serve as a testament to Rinpac’s commitment to customer satisfaction.

Conclusion

In conclusion, Rinpac’s customized shaped pouches offer a harmonious blend of innovation, practicality, and environmental responsibility. Businesses seeking packaging solutions that stand out in a competitive market can benefit significantly from Rinpac’s expertise. By choosing Rinpac, companies not only enhance their brand image but also contribute to a sustainable future.

Frequently Asked Questions (FAQs)

Are Rinpac’s shaped pouches only suitable for specific industries?

No, Rinpac’s shaped pouches find applications in a wide range of industries, including food and beverage, cosmetics, pharmaceuticals, and pet care.

How involved can I be in the design process of my customized shaped pouch?

Rinpac encourages active customer involvement in the design process, ensuring that the final product aligns with the client’s vision and brand identity.

Is Rinpac’s packaging environmentally friendly?

Yes, Rinpac prioritizes environmental sustainability by offering eco-friendly options and implementing green manufacturing practices.

What sets Rinpac apart from other packaging manufacturers?

Rinpac stands out due to its expertise in innovative design, commitment to quality control, and a global distribution network, ensuring timely and reliable delivery.

How cost-effective are Rinpac’s customized shaped pouches in the long run?

Despite initial customization costs, Rinpac’s pouches prove cost-effective in the long run through increased brand recognition and consumer loyalty.