Home » Market Served » Cannabis Packaging » THC Packaging

THC Packaging

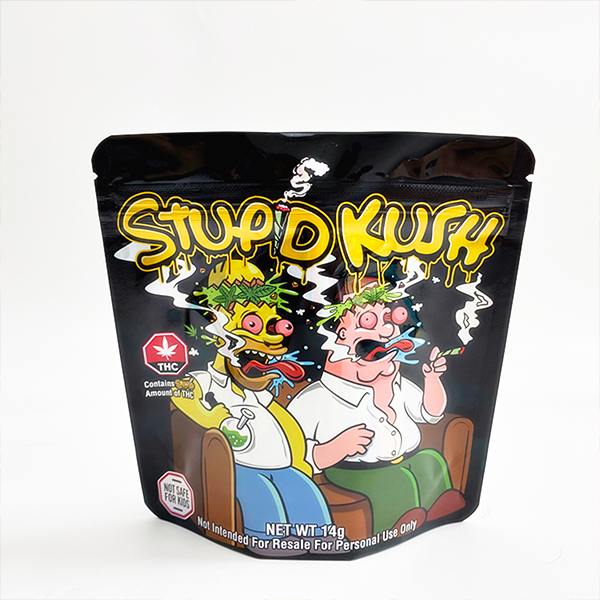

THC packaging should not be geared toward children to mimic major candy and beverage brands. However, restrictive THC packaging and handling regulations make it difficult for operators to meet all requirements.

The Rinpac team has continued refining our process to provide the best materials, add-ons, coatings, and printing options for THC packaging.

Please note that we have a MOQ for our pouch. For pouches in stock, the MOQ is 500 pcs. For customized pouches, please see the MOQ as followed:

1, Digital Printing — 500 pcs

2, Gravure Printing — 5,000pcs

Rinpac assists you throughout your project: bag shape, material, thickness, capacity and printing options. Please contact us or mark your requirements on the inquiry quotation.

Order single or thousands of items at a time. Our warehouse and flexible shipping options are available for last-minute, deadline critical orders.

- Free Sample

*Customization is always available, please mark down your need in cart or just contact us.

Video

Request A Quote

Need something helped in a short time? We’ve got a plan for you.

Related Products

Cannabis Gummies Packaging

Cannabis Flower Packaging

Cannabis Chocolate Packaging

Edible Packaging

THC Packaging

CBD Packaging

Shatter Packaging

Cannabis Concentrate Packaging

Cannabis Pre Roll Packaging

Dispensaries Packaging

Blunt Wrap Packaging

Cannabis Shake Packaging

Cannabis Seed Packaging

Tincture Packaging

Distillate Syringe Packaging

Delta-8 Packaging

THC Packaging: Safeguarding the Green Goodness

In the world of cannabis, proper packaging is an essential element in preserving the quality and integrity of the products. The acronym “THC” stands for delta-9-tetrahydrocannabinol, the primary psychoactive compound found in cannabis. THC packaging is not only about ensuring product safety but also complying with various legal regulations and making a mark in the market through innovative and environmentally friendly solutions.

Introduction

What is THC Packaging?

THC packaging refers to the art and science of packaging cannabis products, such as marijuana and edibles, in a way that ensures safety, compliance with legal requirements, and marketing appeal. It involves the use of different materials, designs, and techniques to protect the product, inform the consumer, and create a unique brand identity.

Importance of Proper THC Packaging

The significance of THC packaging cannot be overstated. It serves several crucial purposes:

- Keeps products fresh and potent

- Protects against contamination and tampering

- Ensures child-resistant packaging

- Conveys essential information and warnings

- Supports marketing and branding efforts

- Contributes to sustainability and environmental responsibility

Regulations and Compliance

Legal Requirements for THC Packaging

The cannabis industry is heavily regulated, and THC packaging is no exception. Regulations can vary from one jurisdiction to another, but some common requirements include child-resistant packaging, clear labeling, and specific warning messages. It’s essential for businesses to understand and comply with these regulations to avoid legal complications.

Packaging Standards and Guidelines

In addition to legal requirements, there are industry standards and guidelines for THC packaging. These standards aim to ensure the safety and quality of the products. They cover aspects like the choice of packaging materials, testing for child resistance, and labeling requirements.

Types of THC Packaging

Child-Resistant Packaging

Child-resistant packaging is a top priority in the cannabis industry. It’s designed to prevent young children from accessing cannabis products, which could be dangerous. This type of packaging often includes features like special closures or locking mechanisms.

Labels and Warning Requirements

Labels play a critical role in THC packaging. They provide vital information about the product, including its potency, ingredients, and usage instructions. Warnings about the potential health risks associated with cannabis use are also mandatory.

Eco-Friendly Packaging Options

With growing concern for the environment, many businesses are exploring eco-friendly packaging options. These may include biodegradable materials, minimalistic designs, and recycling instructions. Sustainable packaging not only appeals to environmentally conscious consumers but also reduces the industry’s carbon footprint.

Challenges in THC Packaging

Keeping Products Fresh

Cannabis products are perishable, and maintaining their freshness is a challenge. Packaging solutions need to provide a barrier against light, air, and moisture, which can degrade the product.

Protection Against Contamination

Contamination is a significant concern in the cannabis industry. Proper packaging should ensure that the product remains free from contaminants and pollutants throughout its shelf life.

Sustainability Concerns

The cannabis industry is increasingly recognizing its responsibility toward sustainability. Reducing waste and adopting eco-friendly practices are becoming integral to THC packaging strategies.

Innovations in THC Packaging

Advanced Sealing and Barrier Technologies

To address freshness and contamination issues, innovative sealing and barrier technologies are emerging. These technologies provide an airtight and lightproof seal, preserving the product’s quality.

Creative and Appealing Designs

Design plays a vital role in attracting customers. Creative and visually appealing packaging can set a brand apart from the competition and leave a lasting impression on consumers.

Sustainable Packaging Solutions

Sustainability is not just a trend but a necessity. Businesses are exploring sustainable packaging solutions, from using recyclable materials to reducing excess packaging.

Branding and Marketing

Creating a Unique Brand Identity

Packaging is an excellent canvas for creating a unique brand identity. It can reflect the values and personality of a brand, making it memorable to consumers.

Connecting with the Target Audience

Effective packaging should resonate with the target audience, helping consumers feel a connection with the product and the brand.

Using Packaging as a Marketing Tool

Packaging can be a powerful marketing tool, conveying a brand’s message and values. Clever packaging can be a conversation starter and generate buzz.

Future Trends in THC Packaging

Personalized Packaging Solutions

As the industry evolves, personalization is becoming more important. Businesses are exploring ways to provide unique packaging experiences for customers.

Integration of Technology

Technology, such as QR codes for product information, is being integrated into packaging to enhance the user experience and provide essential information.

Impact of Changing Regulations

The landscape of cannabis regulations is continually evolving. Businesses need to stay informed and adapt their packaging strategies accordingly.

Ensuring Safety and Security

Preventing Access by Children

Child-resistant packaging is vital for ensuring that cannabis products do not end up in the wrong hands.

Protection Against Counterfeiting

Counterfeiting is a growing concern. Packaging can include security features to help consumers identify genuine products.

Maintaining Product Integrity

Preserving the integrity of the product is crucial for consumers to have a consistent and reliable experience.

The Environmental Impact

Sustainable Materials and Practices

The cannabis industry is embracing sustainability by adopting eco-friendly materials and practices.

Recycling and Waste Management

Efficient recycling and waste management strategies can reduce the environmental impact of cannabis packaging.

Reducing the Carbon Footprint

Reducing the carbon footprint is a priority for many cannabis businesses, and packaging is a significant part of that effort.

Conclusion

In conclusion, THC packaging is a multifaceted field that plays a pivotal role in the cannabis industry. It is not merely a matter of enclosing products but a comprehensive strategy that involves compliance, innovation, branding, and environmental responsibility. As the cannabis industry continues to evolve, so will the art and science of THC packaging.

FAQs

1. What are the legal requirements for THC packaging?

The legal requirements for THC packaging can vary by jurisdiction but often include child-resistant packaging, clear labeling, and specific warning messages.

2. Why is child-resistant packaging essential in the cannabis industry?

Child-resistant packaging is crucial to prevent young children from accessing cannabis products, which could be dangerous to their health.

3. How does sustainable packaging benefit the cannabis industry?

Sustainable packaging benefits the cannabis industry by reducing its environmental impact and appealing to environmentally conscious consumers.

4. What role does branding play in THC packaging?

Branding is essential in THC packaging as it creates a unique identity for a brand and connects with the target audience, making products more memorable.

5. How can businesses stay informed about changing cannabis regulations?

To stay informed about changing cannabis regulations, businesses should regularly monitor updates from regulatory authorities and industry associations and seek legal counsel when necessary.