Home » Market Served » Cannabis Packaging » Distillate Syringe Packaging

Distillate Syringe Packaging

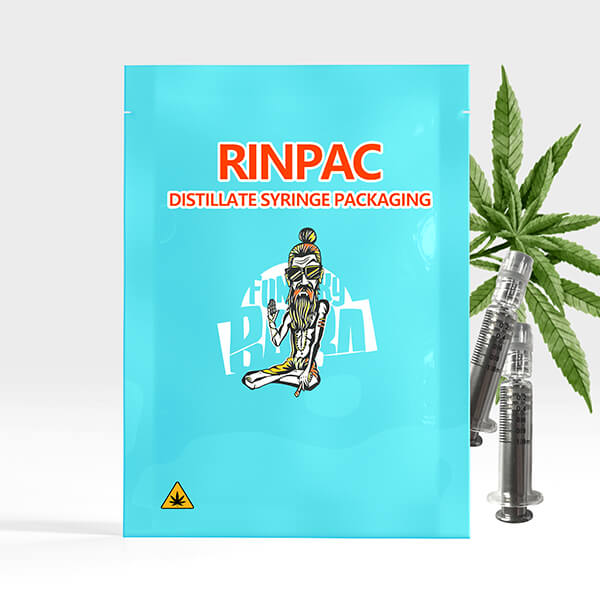

A distillate syringe is one of the best concentrate packaging types for cutting back waste. Rinpac distillate syringe packaging is the perfect way to display our syringe and needle.

Please note that we have a MOQ for our pouch. For pouches in stock, the MOQ is 500 pcs. For customized pouches, please see the MOQ as followed:

1, Digital Printing — 500 pcs

2, Gravure Printing — 5,000pcs

Rinpac assists you throughout your project: bag shape, material, thickness, capacity and printing options. Please contact us or mark your requirements on the inquiry quotation.

Order single or thousands of items at a time. Our warehouse and flexible shipping options are available for last-minute, deadline critical orders.

- Free Sample

*Customization is always available, please mark down your need in cart or just contact us.

Request A Quote

Need something helped in a short time? We’ve got a plan for you.

Related Products

Cannabis Gummies Packaging

Cannabis Flower Packaging

Cannabis Chocolate Packaging

Edible Packaging

THC Packaging

CBD Packaging

Shatter Packaging

Cannabis Concentrate Packaging

Cannabis Pre Roll Packaging

Dispensaries Packaging

Blunt Wrap Packaging

Cannabis Shake Packaging

Cannabis Seed Packaging

Tincture Packaging

Distillate Syringe Packaging

Delta-8 Packaging

Distillate Syringe Packaging: Ensuring Quality and Safety for Cannabis Extracts

In the world of cannabis concentrates, distillates are a prized form of extraction known for their purity and potency. Distillate syringes have become a popular choice for both recreational and medicinal users, offering precise dosing and a clean, versatile product. This article delves into the art of distillate syringe packaging, exploring the various aspects that ensure the quality and safety of these cannabis extracts.

Introduction

Distillate syringes contain highly concentrated cannabis oil, which is a valuable and sensitive product. Packaging plays a pivotal role in preserving the quality, safety, and brand identity of these extracts. In this article, we will explore the multifaceted world of distillate syringe packaging, addressing various aspects that manufacturers and consumers should consider.

What is Distillate Syringe Packaging?

Distillate syringe packaging refers to the containers, materials, and design used to house cannabis distillates. Distillates are made through a process that purifies cannabinoids and removes impurities, resulting in a highly potent product. The packaging should reflect this purity and keep the product safe from external factors.

The Importance of Quality Packaging

Quality packaging is paramount for distillate syringes. It not only protects the product but also conveys a sense of trust to the consumer. Inferior packaging can compromise the product’s integrity, affecting both its quality and safety.

Protecting the Product: Airtight Seals

One of the primary functions of distillate syringe packaging is to maintain the airtight seal. This seal ensures that the product remains free from contaminants, degradation, and oxidation, preserving its purity.

Labels and Branding

Branding is crucial in the cannabis industry. Labels should provide essential information such as strain, dosage, and testing results, as well as reflect the brand’s image. A well-designed label can make a product stand out on dispensary shelves.

Childproofing and Safety Regulations

Ensuring that distillate syringes are childproof is not only a legal requirement but a moral obligation. Stringent childproofing measures must be in place to prevent accidental ingestion.

Convenience and User Experience

The packaging should be user-friendly, allowing for easy and precise dosing. A well-designed syringe should provide a smooth and controlled dispensing experience for the consumer.

Materials Used in Packaging

The choice of materials for packaging plays a significant role in sustainability and product safety. Eco-friendly materials and recyclable options are increasingly favored in the cannabis industry.

Sustainability in Packaging

Environmental responsibility is a growing concern. Sustainable packaging not only helps the planet but also appeals to consumers who value eco-conscious choices.

Storage and Shelf Life

Proper storage and packaging can extend the shelf life of distillate syringes. Factors such as temperature, light, and humidity should be considered.

Compliance with State Laws

Different states have varying regulations regarding cannabis packaging. Manufacturers must stay informed and comply with local laws to avoid legal issues.

Distribution and Transportation

Packaging must withstand the rigors of distribution and transportation. Ensuring that products reach their destination intact is crucial for manufacturers and consumers alike.

Consumer Education

Educating consumers about the importance of proper storage and usage is essential. Packaging can play a role in providing clear instructions and warnings.

Challenges in Distillate Syringe Packaging

The cannabis industry faces unique challenges, including evolving regulations and a competitive market. Overcoming these challenges is vital for businesses in this sector.

Conclusion

Distillate syringe packaging is a critical element in the cannabis industry. It ensures that a high-value product retains its quality and safety from production to consumption. Manufacturers, regulators, and consumers must work together to create a secure and thriving market for distillate syringes.

Frequently Asked Questions (FAQs)

Are distillate syringes legal in all states?

The legality of distillate syringes varies by state. It’s essential to know the local laws and regulations in your area.

Can I reuse distillate syringe packaging?

Reusing packaging is not recommended, as it may compromise the product’s integrity and safety.

How should I store distillate syringes to ensure their quality?

Store distillate syringes in a cool, dark place and keep them airtight to maintain their quality.

What should I look for in a reputable distillate syringe brand?

A reputable brand should have quality packaging, clear labeling, and compliance with safety regulations.

Can I recycle distillate syringe packaging?

Many distillate syringe packaging materials are recyclable. Check with your local recycling facilities for guidance.